- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Aug . 10, 2025 05:40 Back to list

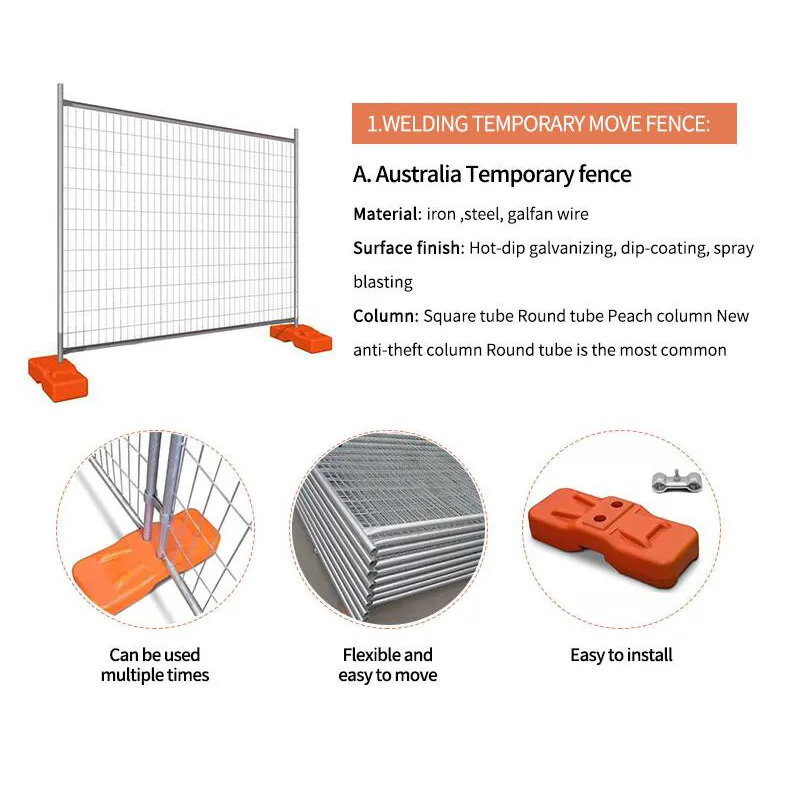

Wholesale Australian Temporary Fence - Durable, Secure Solutions

Navigating the Landscape of Wholesale Australian Temporary Fencing: Market Dynamics and Innovations

In the rapidly evolving sectors of construction, event management, and public safety across Australia, the demand for robust, reliable, and compliant temporary fencing solutions is at an all-time high. A comprehensive understanding of the market dynamics pertaining to wholesale australian temporary fence systems is paramount for businesses seeking to optimize their operational efficiency and ensure adherence to stringent Australian standards. This article delves into the intricate facets of this specialized product segment, exploring current industry trends that are shaping its trajectory, from the increasing emphasis on sustainable materials and enhanced durability to the integration of smart technologies for better asset management. The Australian temporary fencing market is characterized by a unique set of regulatory requirements, notably the AS 4687-2007 standard for temporary fencing and hoardings, which dictates specific performance criteria including wind loading, panel stability, and gate mechanisms. This standard is crucial, as non-compliance can lead to significant penalties, project delays, and safety hazards, making the selection of a reputable supplier offering compliant products non-negotiable for any large-scale project. Furthermore, the burgeoning infrastructure development across major Australian cities and regional hubs, coupled with a robust calendar of public events and festivals, consistently fuels the need for high-quality, easily deployable, and secure temporary perimeter solutions. The shift towards lightweight yet resilient materials, advanced corrosion protection techniques like hot-dip galvanization, and modular designs that facilitate rapid deployment and dismantling, are key trends driving innovation within the `australian temporary fence` manufacturing sector. As businesses increasingly seek economies of scale and consistent product quality, the role of reliable `wholesale australian temporary fence` suppliers becomes critically important, requiring a deep dive into not only the product specifications but also the manufacturing integrity and supply chain efficiencies offered by various providers. Understanding these trends empowers buyers to make informed decisions that align with both project requirements and long-term business objectives, ensuring a superior return on investment through enhanced safety, extended product lifespan, and reduced operational overheads. The market also sees a growing demand for specialized solutions such as `temporary pool fencing australia`, which adheres to even more rigorous safety standards designed to prevent accidental drownings, underscoring the diverse and critical applications of these fencing systems. This detailed exploration aims to provide B2B decision-makers and technical personnel with the insights necessary to navigate this complex market, ensuring they procure solutions that are not only cost-effective but also embody the highest standards of safety, durability, and regulatory compliance.

The Genesis of Strength: Unpacking the Manufacturing Process of Australian Temporary Fence Panels

The robust performance and extended service life of a high-quality Australian Temporary Fence Panel are direct outcomes of a meticulously engineered manufacturing process, one that integrates advanced material science with precise fabrication techniques. This detailed journey begins with the careful selection of raw materials, predominantly high-grade steel, which forms the skeletal structure of the fence panels. For `wholesale australian temporary fence` products, the steel typically used is low-carbon steel, chosen for its excellent weldability and malleability, allowing for the formation of the required frame and mesh without compromising structural integrity. The manufacturing process can be conceptually broken down into several critical stages, each contributing to the final product's compliance with demanding standards like AS 4687-2007 and ISO 9001 quality management systems. The initial phase involves the precise cutting and bending of steel tubes and wires. The tubes, commonly galvanized before fabrication or post-galvanized, are shaped to form the outer frame, while the wires are prepared for the infill mesh. This infill mesh is typically an anti-climb design, characterized by small aperture openings, often 60x150mm or 75x150mm, which makes it exceedingly difficult to climb, thereby enhancing site security. The wires are precisely welded to create a strong, uniform mesh panel. Following the preparation of the frame and mesh, the core manufacturing process commences with automated welding. Robotic welding systems are often employed to ensure consistent, strong, and clean weld points between the mesh and the tubular frame. This precise fabrication minimizes human error and guarantees uniform panel dimensions and structural integrity across large batches of `australia temporary fencing`. The quality of these welds is paramount for the fence's overall stability and resistance to impact and environmental stresses. Once the welding is complete, the panels undergo a crucial surface treatment: galvanization. Two primary methods are common: pre-galvanization, where galvanized steel tubes and wires are used from the outset, and post-weld hot-dip galvanization. Hot-dip galvanization involves immersing the fabricated steel panel into a bath of molten zinc at approximately 450°C. This process creates a metallurgically bonded zinc coating that offers superior corrosion resistance compared to other surface treatments. The thickness of this zinc layer is critical, with specifications often adhering to AS/NZS 4680:2006 for hot-dip galvanized coatings, ensuring a service life of many years, even in harsh Australian coastal environments. The zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and extending the life of the `temp fence australia`. After galvanization, some manufacturers apply an additional layer of protection, such as powder coating, which not only provides an extra barrier against corrosion but also offers aesthetic versatility, allowing for different color options to blend with surroundings or meet specific branding requirements. This multi-layer protection significantly enhances the durability and longevity of the temporary fence panels. Throughout these stages, rigorous quality control and testing standards are applied. Before, during, and after fabrication, materials are inspected for conformity to specifications. Post-galvanization, visual inspections are performed to check for uniform coating, drips, or bare spots. Dimension checks ensure panels meet specified lengths, heights, and mesh sizes. Strength tests, including weld strength and impact resistance, are also conducted to verify that the panels can withstand typical operational stresses and comply with AS 4687-2007, which dictates specific wind loading capacities. Manufacturers adhering to ISO 9001:2015 quality management systems implement comprehensive inspection protocols at every step, from raw material receipt to final product dispatch, ensuring that every `wholesale australian temporary fence` panel leaving their facility meets the highest benchmarks for quality and performance. This meticulous attention to detail in the manufacturing process guarantees that the resulting temporary fencing solutions are not only structurally sound but also offer exceptional longevity and reliability in diverse application settings, from bustling construction sites in urban centers to remote mining operations and temporary infrastructure projects in the harsh Australian outback. The commitment to these advanced manufacturing practices is what differentiates a premium product capable of delivering optimal performance and safety benefits throughout its extensive service life.

Technical Specifications and Performance Benchmarks for Australian Temporary Fencing

Understanding the precise technical parameters and performance benchmarks is crucial when evaluating `wholesale australian temporary fence` solutions. These specifications not only dictate the product's suitability for various applications but also ensure compliance with critical Australian standards, notably AS 4687-2007 for Temporary Fencing and Hoardings. This standard sets forth minimum requirements for structural integrity, stability, and safety, specifically addressing aspects like wind loading, impact resistance, and panel interlocking mechanisms. Manufacturers of premium `australian temporary fence` panels adhere rigorously to these guidelines, often exceeding them to provide a superior product. A typical panel stands at a height of 2.1 meters (approximately 82.7 inches) and a width of 2.4 meters (approximately 94.5 inches), dimensions proven to offer optimal coverage and stability for most site requirements. The frame, the backbone of the panel, is typically constructed from high-quality galvanized steel tubing, with common specifications including a 32mm or 42mm outside diameter (OD) and a wall thickness ranging from 1.5mm to 2.0mm. The choice of tube diameter and thickness directly influences the panel's rigidity and resistance to bending under external forces. The infill mesh, designed to prevent unauthorized access and climbing, is usually made from 4mm or 5mm galvanized wire, forming a tight grid pattern, commonly 60x150mm or 75x150mm. This anti-climb mesh design is a key feature, enhancing security by making it difficult for individuals to gain a foothold. The galvanization process, typically hot-dip galvanization, ensures a minimum zinc coating thickness of 42 microns or higher, providing exceptional corrosion resistance in diverse environmental conditions, including coastal areas with high salt content. This level of galvanization is critical for the long-term durability and extended service life of `temp fence australia` products, minimizing rust and degradation over years of repeated use. The stability of these temporary fence systems is further bolstered by robust concrete or plastic feet, weighing between 25kg to 35kg each, which provide a stable base even in challenging ground conditions. Clamping mechanisms, often made from galvanized steel, are designed for quick and secure panel-to-panel connection, ensuring the fence line remains continuous and stable. Furthermore, gates designed to integrate seamlessly with these panels are available, featuring heavy-duty hinges and secure latching systems to control access points. These gates also adhere to the same stringent material and manufacturing standards as the panels. The combined effect of these carefully chosen materials and precise engineering ensures that a high-quality `wholesale australian temporary fence` system can withstand significant wind loads – often rated to Category C cyclonic conditions when properly installed with bracing – and resist impact, thereby safeguarding construction sites, events, and public areas. When assessing suppliers, it is imperative to request detailed technical data sheets, certifications (such as ISO 9001 for quality management and AS 4687-2007 compliance reports), and specific test results to verify these critical performance parameters, ensuring that the chosen fencing solution meets or exceeds all project-specific and regulatory requirements, including those for specialized applications like `temporary pool fencing australia` which demands even tighter mesh and specific gate latching mechanisms for child safety.

Typical Australian Temporary Fence Panel Specifications

Beyond Compliance: Technical Advantages and Performance Metrics that Elevate Australian Temporary Fencing

While adherence to AS 4687-2007 is non-negotiable for `wholesale australian temporary fence` solutions, leading manufacturers go beyond mere compliance, embedding technical advantages and performance metrics that significantly enhance the utility, durability, and cost-effectiveness of their products. These advancements are crucial for B2B clients who prioritize long-term value, operational efficiency, and superior safety on their sites. A primary technical advantage lies in the superior corrosion resistance achieved through advanced galvanization techniques. While standard hot-dip galvanization provides a robust zinc coating, some manufacturers implement additional passivation treatments or duplex coating systems (galvanization followed by powder coating) that extend the life of the fence panels by an additional 20-30%, even in aggressive environments such as coastal areas, industrial zones, or sites exposed to corrosive chemicals. This enhanced protection translates directly into a lower total cost of ownership over the product's extended lifespan, as replacement cycles are significantly prolonged. Another critical performance metric is wind loading capacity. While AS 4687-2007 provides a baseline, high-quality `australian temporary fence` systems are often engineered with specific bracing and support systems, such as temporary fence stays or anti-gale bracing, that allow them to withstand much higher wind speeds—often categorized for cyclonic regions (e.g., Category C or D wind ratings). This resilience is achieved through stronger welds, thicker gauge steel in critical stress points, and innovative base designs that improve stability. This capability is paramount for projects in exposed locations or during periods of adverse weather, preventing fence blow-downs that can lead to significant safety risks, property damage, and project delays. The design of the infill mesh also offers distinct technical advantages. While the standard anti-climb mesh (small aperture) is effective, some premium `temp fence australia` solutions incorporate even tighter mesh patterns or reinforced wire gauges, making them virtually impossible to climb without specialized tools and significantly increasing the deterrence factor for intruders. This is particularly valuable for high-security construction sites or restricted access zones during events. Furthermore, the interlocking and clamping mechanisms are engineered for both security and ease of use. Premium clamps feature robust construction, often made from pressed steel with high-tensile bolts, ensuring a secure connection between panels that resists tampering and accidental dislodgement. The design also often allows for quicker assembly and disassembly, reducing labor costs during installation and removal phases, a significant operational advantage for companies managing multiple sites. Manufacturers also focus on the integration of various accessories that enhance functionality and safety. This includes heavy-duty gates with tamper-proof latches, often equipped with self-closing mechanisms for pool fencing applications, and pedestrian gates that offer controlled access. Additionally, specialized safety features like highly visible reflective tape or mesh screening for dust control can be integrated, adding further value. For instance, temporary pool fencing Australia often features specific self-closing and self-latching gate hardware that complies with stringent pool safety regulations, going beyond the general requirements for other temporary fencing applications. The structural integrity is often verified through independent third-party testing, including finite element analysis (FEA) for complex designs and physical load-bearing tests. These tests provide quantifiable data on the fence's resistance to impact, crowd pressure, and high winds, offering empirical evidence of its superior performance. When considering a `wholesale australian temporary fence` supplier, probing into these advanced technical specifications and requesting corresponding test data and certifications will distinguish a basic compliant product from a genuinely superior solution that offers enhanced safety, durability, and long-term economic benefits, ensuring a resilient and secure perimeter for any demanding application.

Versatility in Action: Diverse Application Scenarios for Wholesale Australian Temporary Fencing

The inherent versatility and robust design of `wholesale australian temporary fence` systems make them indispensable across a multitude of industries and specific application scenarios throughout Australia. Their ability to provide rapid, secure, and compliant perimeter control solutions ensures safety and order in environments ranging from dynamic construction sites to large-scale public gatherings. In the construction industry, which is a primary consumer, temporary fencing is critical for establishing secure boundaries around active work zones, protecting the public from potential hazards, preventing unauthorized access to equipment and materials, and clearly defining pedestrian pathways. These fences are extensively used for residential, commercial, and industrial building projects, civil engineering works, road constructions, and demolition sites. The modular nature of `australian temporary fence` panels allows for easy reconfiguration as project phases evolve, providing adaptable security solutions that move with the construction progress. For instance, on a major infrastructure project, the fencing might cordon off a large area initially, then be reconfigured to secure specific work cells or material laydown areas as the project advances. Beyond construction, the events management sector heavily relies on `temp fence australia` for crowd control, perimeter security, and defining distinct zones at festivals, concerts, sporting events, and exhibitions. These fences guide pedestrian flow, manage queues, secure VIP areas, and prevent gate-crashing, contributing significantly to public safety and event logistics. Their ease of installation and removal makes them ideal for temporary event setups that need to be deployed and dismantled quickly. Another crucial application is in public works and civil maintenance. When utility repairs, roadworks, or landscaping projects are underway in public spaces, temporary fencing is essential for isolating the work area, protecting passersby, and preventing accidental entry. This includes everything from trenching work to tree removal operations, where a clear, visible barrier is paramount for safety. Mining and resource sectors also frequently employ `wholesale australian temporary fence` for securing exploration sites, temporary processing areas, and rehabilitation zones, particularly in remote and challenging terrains where durable and easily deployable solutions are a must. The robust galvanization ensures they withstand harsh environmental conditions prevalent in these areas. Furthermore, the specialized segment of `temporary pool fencing australia` addresses a critical safety need. Mandated by law in most Australian states, these fences provide a secure barrier around swimming pools, both permanent and temporary (e.g., portable or inflatable pools), to prevent accidental drownings, especially among young children. These specific fences often feature tighter mesh, self-closing and self-latching gates, and specific height requirements to meet the stringent AS 1926.1-2012 standard for swimming pool safety barriers. Even in residential settings, temporary fencing finds use during landscaping projects, home renovations, or for temporary pet enclosures. The rapid deployment capability makes these fences ideal for emergency response situations, such as delineating hazardous areas after natural disasters or controlling access during public health crises. The common advantage across all these scenarios is the system's balance of strength, compliance with safety standards, and logistical efficiency. The ability to rapidly deploy, reconfigure, and remove these fences makes them an economically viable and highly effective solution for managing temporary access and security requirements across Australia’s dynamic industrial and public landscape.

Strategic Procurement: Manufacturer Comparison and Selection Criteria for Wholesale Australian Temporary Fencing

Selecting the right manufacturer for `wholesale australian temporary fence` solutions is a critical strategic decision that impacts not only immediate project costs but also long-term operational efficiency, safety compliance, and overall return on investment. The market is populated by numerous suppliers, each offering varying levels of product quality, service, and pricing structures. A thorough manufacturer comparison is therefore essential, focusing on a comprehensive set of selection criteria that extend beyond mere cost. Firstly, paramount importance must be placed on Compliance and Certifications. The chosen manufacturer must unequivocally adhere to Australian Standards, specifically AS 4687-2007 for temporary fencing and AS 1926.1-2012 for `temporary pool fencing australia`. Beyond product compliance, look for manufacturers holding ISO 9001:2015 certification for their quality management systems, indicating a commitment to consistent quality and continuous improvement. Verifiable test reports for wind loading, impact resistance, and material specifications (e.g., galvanization thickness as per AS/NZS 4680:2006) should be readily available. Secondly, Material Quality and Manufacturing Integrity are non-negotiable. Inquire about the grade of steel used, the type and thickness of galvanization (hot-dip galvanization being superior for longevity), and the welding processes employed. Robotic welding, for example, often indicates higher precision and stronger welds compared to manual methods. A manufacturer's transparency regarding their raw material sourcing and production line processes speaks volumes about their confidence in product quality. Thirdly, Product Range and Customization Capabilities are vital for diverse operational needs. A comprehensive supplier should offer not only standard fence panels but also a full suite of accessories including various types of bases (concrete, plastic), clamps, stays, gates (pedestrian, vehicle), and specialized solutions like high-visibility screening or heavy-duty bracing for cyclonic regions. The ability to provide customized panel sizes, gate configurations, or specific branding (e.g., company logos on panels) can be a significant advantage, allowing clients to tailor solutions precisely to their project requirements. Fourthly, Supply Chain Efficiency and Delivery Logistics are crucial for timely project execution. Evaluate the manufacturer's capacity to handle large `wholesale australian temporary fence` orders, their average lead times, and their logistical network for delivery across Australia. A manufacturer with established distribution channels and efficient warehousing can significantly reduce waiting times and ensure consistent supply, minimizing project delays. Fifthly, After-Sales Support and Warranty provide peace of mind. A reputable manufacturer stands behind its products with clear warranty terms covering defects in material and workmanship. Furthermore, responsive customer support for technical queries, installation guidance, and troubleshooting reflects a commitment to client satisfaction. Consider the manufacturer's service history, years in business, and reputation within the industry. Companies that have served the Australian market for a significant period often possess invaluable experience and a proven track record. Lastly, while not the sole determinant, Pricing and Value Proposition must be assessed. Compare quotations from multiple manufacturers, but always consider the overall value rather than just the lowest price. A slightly higher upfront cost for a superior quality `australian temporary fence` with extended lifespan, reduced maintenance, and enhanced safety features will invariably yield better long-term value than a cheaper, less durable alternative that may require frequent repairs or early replacement. Engaging in detailed discussions with potential suppliers, requesting samples, and reviewing their client testimonials or case studies will provide further insights into their capabilities and reliability, ensuring a procurement decision that aligns perfectly with strategic objectives for optimal site security and operational excellence.

Tailored Security: Customization Options and Bespoke Solutions for Australian Temporary Fencing Needs

While standard `wholesale australian temporary fence` panels meet a broad spectrum of requirements, the dynamic and often unique demands of large-scale projects, specialized events, or complex industrial sites frequently necessitate tailored security solutions. Leading manufacturers offer extensive customization options, allowing B2B clients to specify `australian temporary fence` systems that are perfectly aligned with their precise operational, safety, and aesthetic needs, thereby maximizing efficiency and effectiveness. One of the most common customization requests revolves around panel dimensions. While 2.1m x 2.4m is standard, projects might require taller panels for enhanced security, shorter panels for specific crowd control barriers, or panels of varying widths to perfectly fit irregular perimeters without excessive cutting or awkward gaps. This precision fitting reduces installation time and improves overall site integrity. Beyond standard dimensions, the mesh specification can be customized. While common anti-climb mesh (e.g., 60x150mm) is widely adopted, some high-security applications may benefit from even smaller mesh apertures or thicker wire gauges to deter determined intruders or prevent the passage of small items. Conversely, for certain applications where visibility is key, a slightly wider mesh might be preferable, though always ensuring compliance with relevant safety standards. Surface finishes and color options represent another area for significant customization. While hot-dip galvanization is the gold standard for corrosion protection, clients may opt for additional powder coating in specific RAL colors to match corporate branding, blend with architectural aesthetics, or enhance visibility for safety purposes. This duplex coating not only adds a layer of visual appeal but also provides an extra barrier against environmental degradation, extending the lifespan of the `temp fence australia`. Gate configurations are frequently customized to manage specific access control needs. This includes variations in gate width (single pedestrian gates, double vehicle gates), the inclusion of self-closing and self-latching mechanisms (critical for `temporary pool fencing australia` compliance), and the integration of specific locking mechanisms or electronic access control systems. Some manufacturers can also design gates to swing in a particular direction or to be removable for occasional wide access. For projects in high-wind regions or those requiring exceptional stability, specialized bracing and support systems can be custom-engineered. This might involve heavier duty temporary fence stays, advanced foot designs for uneven terrain, or custom-fabricated counterweights to ensure the fence system withstands extreme weather conditions beyond standard ratings, often verified through specific wind tunnel testing or engineering calculations. The integration of branding and signage directly onto the fence panels is another valuable customization. This can range from attaching specific warning signs and directional arrows to incorporating company logos or project details onto banner mesh or directly onto the fence fabric, turning the perimeter into a dynamic advertising or informational medium. Furthermore, leading manufacturers often provide bespoke solutions for unique challenges. This could involve designing fence systems for highly corrosive environments (e.g., using specific marine-grade coatings or even alternative materials in extreme cases), creating temporary acoustic barriers for noise reduction, or developing specialized hoarding panels that integrate both security and aesthetic requirements. The process for engaging in such customization typically involves a detailed consultation with the manufacturer's engineering or design team. This collaborative approach allows for a thorough assessment of project-specific risks, environmental factors, regulatory requirements, and budget constraints, culminating in a tailored `wholesale australian temporary fence` solution that delivers optimal performance, enhanced safety, and long-term cost-effectiveness. This ability to provide bespoke solutions underscores a manufacturer's expertise and commitment to meeting the precise and evolving needs of their diverse B2B clientele across Australia.

Real-World Impact: Application Case Studies and Client Success Stories in Australian Temporary Fencing

The tangible benefits of high-quality `wholesale australian temporary fence` systems are best illustrated through real-world application case studies and testimonials from satisfied clients. These examples underscore how robust, compliant, and efficiently deployable fencing solutions contribute directly to project success, safety, and operational continuity across diverse sectors. Case Study 1: Major Urban Infrastructure Project (Sydney Metro Line Extension) A consortium undertaking a multi-billion-dollar metro line extension in Sydney required thousands of linear meters of temporary fencing to secure active construction corridors, manage pedestrian flow in high-traffic urban areas, and protect sensitive equipment. The challenge involved not only securing vast perimeters but also ensuring compliance with stringent safety regulations, mitigating noise and dust, and maintaining a professional appearance in a public-facing environment. A reputable `australian temporary fence` manufacturer supplied a tailored solution featuring 2.1m high galvanized panels with specialized anti-climb mesh, integrated with high-visibility orange screening for dust suppression and improved aesthetics. Heavy-duty concrete feet and wind-rated bracing systems were implemented to withstand urban wind gusts and maintain stability around active excavation sites. The rapid deployment capabilities of the `temp fence australia` systems, combined with clearly marked pedestrian access points and securely latched vehicle gates, ensured that the project could scale its security needs quickly, maintain public safety, and minimize disruption to surrounding businesses and residents. Client feedback highlighted the fencing's exceptional durability, ease of re-configuration as construction progressed, and the professional support provided by the supplier in ensuring compliance and timely delivery. The investment in high-quality temporary fencing directly contributed to a safer site, reduced security incidents, and positive community perception. Case Study 2: Large-Scale Music Festival (Regional Victoria) An event management company organizing a multi-day music festival in regional Victoria faced the challenge of securing a vast open-air venue, controlling access points, delineating various zones (stage, camping, vendor, VIP), and managing crowd flow for over 50,000 attendees. The primary requirement was for a versatile `wholesale australian temporary fence` solution that could be rapidly installed, withstand significant crowd pressure, and be easily dismantled post-event. The chosen supplier provided a mix of standard temporary fence panels for outer perimeters and specialized crowd control barriers for stage fronts and high-density areas. All panels were hot-dip galvanized for durability and featured a robust clamping system for secure interconnection. Crucially, specific pedestrian and vehicle gate systems were integrated with clear signage, allowing for efficient entry and exit management while preventing unauthorized access. The rapid deployment, facilitated by the fence's modular design and lightweight yet strong components, allowed for setup within a tight pre-event schedule. The stability of the fences, even with large crowds pressing against them, was a key success factor, ensuring public safety throughout the festival. The client commended the supplier for their logistical efficiency and the reliability of the fencing, which minimized security breaches and facilitated a smooth, well-managed event. Case Study 3: Residential Pool Construction & Renovation (Perth, WA) A pool construction company in Perth frequently required reliable `temporary pool fencing australia` solutions to comply with Western Australian state regulations (AS 1926.1-2012) during new pool installations and renovations. The critical need was for fences that offered uncompromising child safety, were quick to install and remove, and were robust enough for repeated use. The chosen supplier provided specialized temporary pool fence panels featuring tighter mesh gaps (typically 50x50mm or smaller) to prevent climbing, a minimum height of 1.2 meters, and critically, self-closing and self-latching gates that automatically secured the pool area. These fences were supplied with compliant plastic or concrete feet designed for stability on various ground surfaces. The key advantage highlighted by the client was the peace of mind provided by knowing the temporary fencing fully met legislative requirements, thereby avoiding fines and ensuring the utmost safety for children in proximity to construction sites. The ease of installation and the ability to reuse the fencing across multiple projects significantly enhanced the company's operational efficiency and cost-effectiveness. These case studies underscore the pivotal role of robust and compliant `wholesale australian temporary fence` solutions in safeguarding people, assets, and project timelines across Australia's diverse industrial and public landscapes.

Ensuring Trustworthiness: Quality Assurance, Warranty, Delivery, and Customer Support

For B2B purchasers of `wholesale australian temporary fence` systems, trustworthiness in a supplier is as critical as the product's technical specifications. A reputable manufacturer differentiates itself not just through superior products but also through transparent policies on quality assurance, robust warranty commitments, efficient delivery cycles, and responsive customer support. These pillars collectively build confidence and ensure a smooth, reliable procurement experience, fostering long-term partnerships. Quality Assurance (QA) is fundamental. Beyond the manufacturing process detailed earlier, a trustworthy supplier implements comprehensive QA protocols. This includes rigorous pre-shipment inspections, detailed material traceability records (from raw steel coils to finished fence panels), and adherence to internationally recognized quality management systems such as ISO 9001:2015. They will often conduct internal audits and encourage third-party verification of their products against AS 4687-2007, AS/NZS 4680:2006 (for galvanization), and AS 1926.1-2012 (for `temporary pool fencing australia`). This commitment to quality assurance ensures that every `australian temporary fence` panel you receive consistently meets the highest standards for durability, safety, and performance, reducing the risk of product failure on site and associated liabilities. Warranty Commitment is a direct reflection of a manufacturer's confidence in their product. A reliable supplier will offer a clear and comprehensive warranty covering defects in materials and workmanship for a specified period, typically ranging from 5 to 10 years, or even longer for the galvanization coating. This warranty provides financial protection against unforeseen issues and demonstrates the manufacturer's accountability. Before finalizing a `wholesale australian temporary fence` purchase, it is imperative to thoroughly review the warranty terms, including what is covered, the duration, and the claims process. Delivery Cycle and Logistics are paramount for project timelines. A trustworthy supplier understands the critical nature of timely delivery. They will have established efficient logistical networks, potentially including multiple warehouses or partnerships with reliable freight companies across Australia, to ensure prompt dispatch and transit. They should provide clear communication regarding lead times, order tracking, and potential delays, allowing clients to plan their project schedules effectively. For large `temp fence australia` orders, they should have the capacity to manage bulk shipments and specialized delivery requirements, such as to remote mining sites or limited access urban areas. Customer Support and After-Sales Service further solidify trustworthiness. This includes a dedicated point of contact for inquiries, technical assistance for installation and maintenance, and a responsive mechanism for addressing any issues that may arise post-purchase. An excellent supplier will offer expert advice on product selection, help with customized solutions, and provide ongoing support to ensure the optimal performance and longevity of their fencing systems. Their commitment to customer satisfaction extends beyond the sale, aiming to build lasting relationships based on mutual trust and reliability. This holistic approach to client engagement, coupled with transparent policies and a proven track record, empowers B2B decision-makers to select a `wholesale australian temporary fence` partner with confidence, knowing their investment is secured by a commitment to quality, service, and integrity.

Frequently Asked Questions (FAQ)

-

Q: What are the key Australian Standards applicable to temporary fencing?

A: The primary standard is AS 4687-2007 (Temporary Fencing and Hoardings). For temporary fencing around pools, AS 1926.1-2012 (Swimming Pool Safety) is also critical. Galvanization standards typically follow AS/NZS 4680:2006.

-

Q: How do I determine the right quantity of `wholesale australian temporary fence` for my project?

A: Measure the total linear perimeter required and divide by the width of a single panel (typically 2.4 meters). Always add a buffer (e.g., 5-10%) for gates, corners, and potential damage or unforeseen needs. Consult with your supplier for precise calculations.

-

Q: What is the typical lifespan of a hot-dip galvanized `australian temporary fence` panel?

A: With proper hot-dip galvanization meeting AS/NZS 4680:2006 (minimum 42 microns zinc coating), a high-quality temporary fence panel can last 10 to 15 years, and even longer in less corrosive environments, with appropriate care and storage.

-

Q: Can these `temp fence australia` systems withstand high winds?

A: Yes, when properly installed with adequate bracing (stays/supports) and sturdy bases, high-quality temporary fencing systems are engineered to meet specific wind load ratings as per AS 4687-2007. Some systems are designed to withstand cyclonic conditions, but this requires specific anchoring and bracing. Always refer to the manufacturer's wind rating charts and installation guidelines.

-

Q: Are there eco-friendly options for `wholesale australian temporary fence`?

A: While the core material is steel, which is recyclable, focus on suppliers who use recycled steel content in their manufacturing. Additionally, the long lifespan of hot-dip galvanized fences reduces waste compared to less durable alternatives. Opting for plastic bases made from recycled materials is another eco-conscious choice. Look for manufacturers with transparent sustainability practices.

The Horizon of Security: Future Trends and Concluding Thoughts on Australian Temporary Fencing

The sector of `wholesale australian temporary fence` is not static; it is continually evolving, driven by advancements in materials science, increasingly stringent safety regulations, and the integration of smart technologies. As we look towards the future, several key trends are poised to reshape how businesses perceive, procure, and deploy `australian temporary fence` solutions, further enhancing their utility and efficiency. One significant trend is the growing emphasis on smart temporary fencing solutions. This involves integrating IoT (Internet of Things) devices, such as motion sensors, RFID tags for asset tracking, and even small, solar-powered surveillance cameras directly onto fence panels. These smart features allow for real-time monitoring of site perimeters, providing instant alerts for breaches or unauthorized access, thereby significantly enhancing security on construction sites or at large events. For large-scale `wholesale australian temporary fence` deployments, this can lead to reduced reliance on static guarding, optimizing security personnel allocation and leading to considerable cost savings while elevating overall site security. Another emerging trend is the development of lighter, stronger, and more sustainable materials. While galvanized steel remains the industry standard, research into composite materials or advanced alloys that offer comparable strength with reduced weight is ongoing. Lighter panels would drastically reduce logistical costs, simplify handling, and potentially lower installation labor requirements. Furthermore, manufacturers are increasingly focusing on the lifecycle assessment of their products, aiming for processes that minimize environmental impact, including reduced energy consumption during manufacturing and increased use of recycled content in both fence panels and bases. The demand for multi-functional fencing systems is also on the rise. Future `temp fence australia` solutions may integrate features beyond just security, such as embedded LED lighting for improved visibility and safety during nighttime operations, integrated charging points for tools or devices, or modular components that double as scaffolding tie-off points. This convergence of functionalities enhances the value proposition of temporary fencing, transforming it from a simple barrier into a dynamic operational asset. Regulatory landscapes, particularly concerning `temporary pool fencing australia` and general construction site safety, are likely to become even more stringent. This will compel manufacturers to innovate further, ensuring their products not only meet but anticipate future compliance requirements, leading to even more robust and fail-safe designs. The role of data analytics in procurement and asset management will also expand. Businesses will increasingly leverage data on fence usage, damage rates, and maintenance cycles to make more informed purchasing decisions and optimize their inventory, moving towards a more predictive maintenance model for their fencing assets. Finally, the emphasis on customization and modularity will only intensify. As projects become more complex and sites more varied, the ability to rapidly assemble and reconfigure bespoke fencing solutions from a standardized set of high-quality components will be a decisive factor for B2B clients. This will drive innovation in connection systems, base designs, and accessory integration, ensuring `wholesale australian temporary fence` remains the most adaptable and effective solution for temporary perimeter control. In conclusion, the Australian temporary fencing market is dynamic and innovative. Businesses that choose to invest in high-quality, compliant, and forward-thinking `wholesale australian temporary fence` solutions, supported by trustworthy manufacturers, are not just purchasing a product; they are investing in enhanced safety, operational efficiency, and long-term project success. The continuous evolution of this sector promises even more advanced and integrated solutions for the complex security and logistical challenges of tomorrow.

References and Further Reading

- Standards Australia: AS 4687-2007 Temporary fencing and hoardings – Procurement – Design – Construction

- Standards Australia: AS 1926.1-2012 Swimming pool safety – Safety barriers for swimming pools

- Standards Australia: AS/NZS 4680:2006 Hot-dip galvanized (zinc) coatings on fabricated ferrous articles

- International Organization for Standardization: ISO 9001:2015 Quality management systems – Requirements

- SafeWork NSW: Fencing and hoardings for construction sites (Guidance material)

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025