- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Aug . 09, 2025 04:00 Back to list

Explore Crowd Control Barrier Types | Stanchions & Barricades

In today's dynamic public and industrial environments, effective crowd management is not just a logistical necessity but a critical safety imperative. From bustling concerts and sporting events to critical infrastructure sites and large-scale public gatherings, the ability to guide, secure, and protect individuals relies heavily on robust and reliable crowd control solutions. Among these, crowd control barrier types stand as foundational elements, evolving significantly in design, material, and application over the years. This article delves deep into the world of crowd control barriers, exploring industry trends, technical specifications, diverse applications, and the crucial factors to consider when sourcing these essential assets.

The global market for security and safety equipment, including crowd control barricades for sale, has seen consistent growth, driven by increasing public events, heightened security concerns, and regulatory compliance requirements. Reports by market research firms such as Grand View Research and Mordor Intelligence project the global physical security market, encompassing barriers and access control, to reach significant valuations, underscoring the sustained demand for advanced solutions. This trend highlights a shift towards more sophisticated, durable, and versatile crowd control barrier systems that can adapt to various scenarios while ensuring maximum safety and operational efficiency.

Industry Trends and Technological Advancements in Crowd Control Barriers

The evolution of crowd control barrier types is marked by several key trends:

- Enhanced Durability and Materials Science: A move towards higher-grade steels (e.g., Q235, galvanized steel), advanced plastics (HDPE), and composite materials for increased lifespan, corrosion resistance, and lighter weight.

- Modularity and Interlocking Systems: Modern barriers often feature advanced interlocking mechanisms that allow for quick setup, dismantling, and secure formation of long, continuous lines without gaps, significantly improving stability and integrity.

- Smart Integration: Emerging trends include barriers with integrated sensor technology for real-time crowd density monitoring, or those designed for seamless integration with surveillance systems and access control technologies.

- Sustainability: Manufacturers are increasingly focusing on recyclable materials and environmentally friendly production processes, aligning with global sustainability initiatives.

- Customization and Branding: Growing demand for barriers that can be customized with company logos, event branding, or specific color schemes, turning functional equipment into a branding opportunity.

These trends reflect an industry committed to innovation, aiming to provide solutions that are not only effective in managing crowds but also adaptable, sustainable, and economically viable for diverse applications, from high-stakes security perimeters to temporary queue lines.

Key Crowd Control Barrier Types and Their Technical Parameters

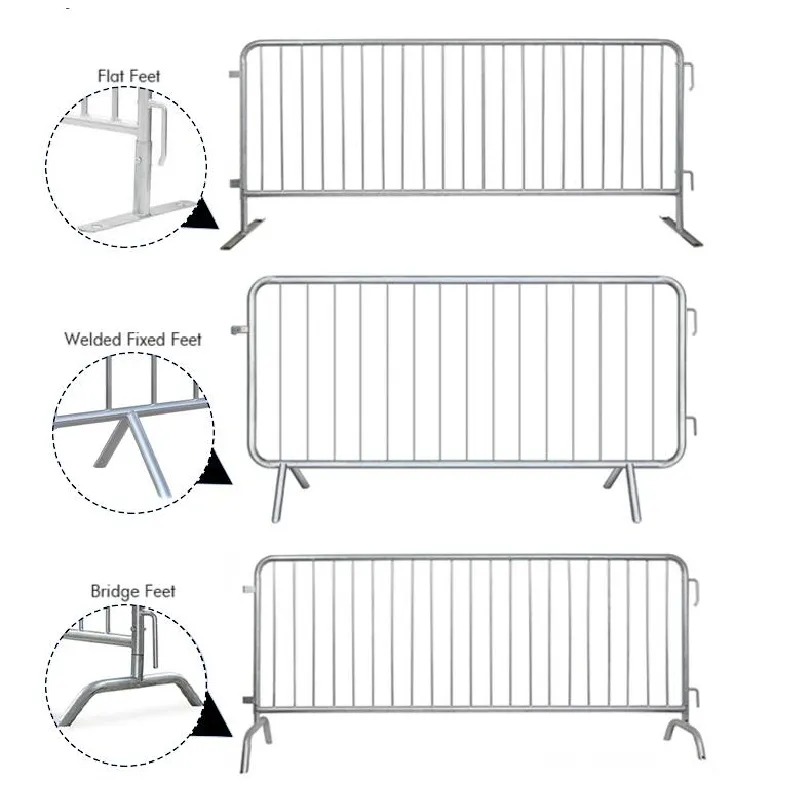

When considering crowd control barrier types, it's essential to understand the distinctions and specifications that make each suitable for different applications. The primary types include:

- Standard Steel Barricades (Bike Rack Barricades): These are the most common, characterized by a robust steel frame and vertical infill bars. They are excellent for defining perimeters, creating queues, and managing pedestrian flow.

- Water-Filled Barriers (Plastic Barriers): Made from durable plastic (usually HDPE), these barriers are lightweight when empty for transport but become incredibly stable once filled with water or sand. Ideal for road closures, construction zones, and temporary traffic redirection.

- Stanchions (Queue Barriers): Typically lighter, often featuring retractable belts or velvet ropes. Primarily used for indoor queuing in retail, airports, museums, and red-carpet events. While not offering physical containment like barricades, they provide clear guidance and organization.

- Heavy-Duty Pedestrian Barriers: Engineered for situations requiring extreme durability and impact resistance, often seen in large-scale public safety events or industrial settings.

- Specialty Barriers: Includes police barriers, anti-climb barriers, and vehicle-stopping barriers designed for specific security threats.

Crowd Control Barrier Types: Parameter Comparison Table

To aid in selection, here's a comparative table of common crowd control barrier types based on key technical parameters:

| Barrier Type | Typical Material | Standard Dimensions (L x H) | Weight (approx.) | Interlocking Mechanism | Portability | Primary Application |

|---|---|---|---|---|---|---|

| Standard Steel Barricade | Hot-dip Galvanized Steel (Q235) | 2.5m x 1.1m (8.2ft x 3.6ft) | 15-25 kg (33-55 lbs) | Hook and Eye/Pin Interlock | High (Stackable) | Concerts, Sporting Events, Queuing, Perimeters |

| Water-Filled Barrier | HDPE (High-Density Polyethylene) | 1.5m - 2.0m x 1.0m (5-6.5ft x 3.3ft) | 8-15 kg (empty); 150-300 kg (filled) | Molded Male/Female Connectors | High (Empty); Low (Filled) | Road Closures, Construction, Traffic Redirection |

| Retractable Belt Stanchion | Stainless Steel, Chrome, Plastic | Base Dia. 32-35cm x H 90-100cm | 6-10 kg (13-22 lbs) | Internal Belt Mechanism | Very High (Lightweight) | Indoor Queuing, VIP Areas, Retail |

| Heavy-Duty Pedestrian Barrier | Thick Wall Steel Tube | 2.0m x 1.2m (6.5ft x 3.9ft) | 30-45 kg (66-99 lbs) | Heavy-Duty Pin/Clamp | Medium (Less Stackable) | High-Security Events, Industrial Zones |

This table highlights that while all serve crowd control, their design and material choices cater to distinct operational requirements and environmental challenges. For instance, crowd control stanchions wholesale are perfect for interior elegance and gentle guidance, whereas heavy-duty steel barriers are built for robust external crowd containment.

The Craft Behind the Control: Manufacturing Process of Our Crowd Control Barriers

At DQ Fence, our Crowd Control Barriers (Product URL: https://www.dqfence.com/crowd-control-barrier.html) are engineered for superior performance and longevity, starting with a meticulous manufacturing process. This commitment to quality ensures that each barrier meets the highest standards of safety, durability, and reliability. We prioritize the selection of premium materials and employ advanced fabrication techniques to produce barriers that excel in diverse challenging environments, including those found in petrochemical, metallurgy, and municipal water supply/drainage industries where corrosion resistance and structural integrity are paramount.

Detailed Manufacturing Process Flow for Crowd Control Barrier

The journey of our crowd control barrier types from raw material to finished product involves several critical stages, each governed by stringent quality control measures:

-

Material Selection & Preparation:

Input: High-quality Q235 carbon steel tubing and flat bars, selected for their excellent strength-to-weight ratio and weldability. Q235 steel is a common structural carbon steel in China, equivalent to ASTM A36, known for its good mechanical properties.

Process: Raw materials undergo initial inspection for defects and dimensional accuracy. They are then cut to precise lengths using automated CNC (Computer Numerical Control) cutting machines, ensuring consistent size and minimizing waste.

(Imagine a diagram showing steel bundles, then precise cuts by a robotic arm with 'Material Infeed' -> 'CNC Cutting' arrows.)

-

Bending and Forming:

Process: The cut steel tubes are fed into precision bending machines to form the top and bottom rails, as well as the 'U' shaped feet. This stage is crucial for ensuring the ergonomic design and stability of the barrier. Advanced hydraulic bending equipment ensures accurate angles and radii, preventing material stress and weakening.

(Visualizing bent tubes emerging from a machine with 'Cut Tubing' -> 'Precision Bending' arrows.)

-

Welding Assembly:

Process: This is a critical stage where all individual components – the main frame, vertical infill bars, and feet – are securely joined. We employ advanced MIG (Metal Inert Gas) welding techniques, often utilizing robotic welding for enhanced precision, consistency, and stronger, cleaner welds. Skilled welders perform final touch-ups and quality checks, ensuring every joint is robust and free from imperfections. This meticulous approach minimizes weak points, enhancing the overall structural integrity and impact resistance of the crowd barriers.

(A scene of robotic welders working on frames, with 'Formed Components' -> 'Robotic MIG Welding' -> 'Manual Inspection' arrows.)

-

Surface Treatment - Hot-Dip Galvanization:

Process: After assembly, the barriers undergo a thorough cleaning process (degreasing, pickling, rinsing) to remove impurities. They are then immersed in a bath of molten zinc at approximately 450°C (840°F). This hot-dip galvanization process creates a metallurgically bonded zinc coating that provides superior corrosion resistance compared to paint or electro-galvanization. This thick, durable coating is self-healing to minor scratches and offers decades of protection against rust, even in harsh outdoor and industrial environments (e.g., coastal areas, chemical plants).

(A depiction of barriers submerged in a hot-dip galvanizing tank, followed by cooling, with 'Welded Barriers' -> 'Cleaning & Fluxing' -> 'Hot-Dip Galvanizing' arrows.)

-

Optional Powder Coating:

Process: For enhanced aesthetics, additional corrosion protection, or specific branding requirements, some barriers receive an electrostatic powder coating. This involves applying a dry powder (polyester or epoxy) to the galvanized surface, which is then cured under heat to form a hard, durable finish. This step adds an extra layer of protection against UV degradation and provides a wide range of color options.

(An image of barriers moving through a powder coating booth, then an oven, with 'Galvanized Barriers' -> 'Powder Application' -> 'Curing Oven' arrows.)

-

Quality Inspection & Testing:

Process: Each finished barrier undergoes a comprehensive multi-point inspection. This includes checks for weld integrity (visual and sometimes destructive testing), coating thickness (using non-destructive methods like magnetic induction), dimensional accuracy against specifications (e.g., ISO 14001, ASTM A123 for galvanization), interlocking functionality, and overall finish. We adhere to international quality standards such as ISO 9001 for our manufacturing processes and ensure compliance with relevant industry benchmarks like ANSI/ASSE A10.33-2012 for construction and demolition operations safety.

(An inspector examining a barrier with measurement tools, 'Finished Barrier' -> 'Final QC Inspection' arrows.)

-

Packaging & Dispatch:

Process: Barriers are carefully stacked and secured with protective wrapping or palletizing to prevent damage during transit. They are then prepared for dispatch, ensuring efficient and safe delivery to client sites globally.

(Barriers stacked and wrapped on pallets, ready for loading onto trucks.)

This rigorous process ensures that our Crowd Control Barriers offer exceptional performance. Their robust construction and superior galvanization result in a lifespan often exceeding 15-20 years under normal use, even in demanding environments. This longevity, coupled with their inherent corrosion resistance, translates into significant long-term cost savings and reduced maintenance for our clients, making them a preferred choice for reliable crowd control barricades for sale.

Technical Advantages and Performance in Application

The meticulous manufacturing process translates into significant technical advantages for our crowd control barrier types:

- Unmatched Durability and Corrosion Resistance: The hot-dip galvanization process provides a thick, resilient zinc coating that offers superior protection against rust and corrosion, even in harsh weather conditions, saline environments (coastal regions), or chemically aggressive industrial settings (e.g., petrochemical plants with exposure to various fumes). This extends the product's lifespan significantly, far outperforming painted or electro-galvanized alternatives.

- Exceptional Structural Integrity: The use of Q235 steel and advanced welding techniques ensures a highly stable and robust structure. This allows the barriers to withstand significant impacts and pressures from large crowds, maintaining their form and function.

- Efficient Interlocking Design: Our barriers feature a robust hook-and-eye or pin interlocking system that allows for quick, seamless connection of multiple units. This creates a continuous, stable barrier line without gaps, enhancing safety and preventing unauthorized entry or egress. The design facilitates rapid deployment and dismantling, crucial for event management.

- Optimized Portability and Storage: Despite their strength, the design allows for efficient stacking, reducing storage space requirements and simplifying transportation logistics.

- Enhanced Safety Features: All edges are carefully deburred, and connections are designed to be smooth, minimizing the risk of injury to both crowd members and installation personnel. The flat feet design further reduces tripping hazards and ensures stable placement on various surfaces.

- Versatile Application: While excellent for public events, their inherent resistance to corrosion and robust build make them ideal for industrial applications such as demarcating safe zones in metallurgical facilities, managing pedestrian traffic around heavy machinery, or securing worksites in water treatment plants, where they resist the corrosive effects of wastewater or chemical spills. Their non-conductive nature (due to the galvanization/coating) can also be beneficial in certain industrial contexts.

These advantages underscore why our crowd barriers are not just simple fences, but engineered solutions designed to perform under pressure, offering a blend of safety, efficiency, and longevity that provides exceptional value.

Application Scenarios: Where Our Barriers Excel

The versatility of our crowd control barrier types means they are indispensable across a broad spectrum of applications:

- Public Events & Festivals: Essential for defining perimeters, creating entry/exit points, managing queues, separating VIP areas, and controlling flow at concerts, music festivals, marathons, and parades. Their quick deployment and secure interlocking capabilities are critical for large-scale temporary setups.

- Sporting Events: Used to manage spectator traffic, secure athlete-only zones, create safe pathways, and define boundaries around fields or tracks.

- Construction Sites: Providing secure perimeters, protecting the public from hazards, and guiding workers within designated zones. Their durability makes them suitable for rough construction environments.

- Traffic Management: Temporarily redirecting vehicles and pedestrians around roadworks, accidents, or special events, ensuring smooth flow and safety.

- Retail & Commercial Venues: Organizing queues during peak hours, creating clear pathways, and managing access to specific sections within stores or exhibition halls. This is where options for crowd control stanchions wholesale often complement the heavier barricades.

- Industrial & Infrastructure Projects (Petrochemical, Metallurgy, Water Treatment): In environments like petrochemical refineries, metallurgical plants, or water/wastewater treatment facilities, our galvanized barriers shine. They are used to:

- Demarcate Exclusion Zones: Clearly separate hazardous areas from pedestrian pathways, enhancing worker safety.

- Control Access: Guide personnel and vehicles to specific entry points, crucial for site security and operational efficiency.

- Contain Spills: In some cases, to create temporary containment around minor leaks or spills (though not primary containment).

- Resist Corrosion: The hot-dip galvanization provides superior resistance to corrosive agents common in these industries (e.g., chemical fumes, wastewater, acidic runoff), ensuring a longer service life and reduced replacement costs compared to untreated barriers.

- Withstand Harsh Conditions: Their robust build is vital in heavy industrial settings where equipment can be subjected to harsh impacts and extreme temperatures.

Our experience spans thousands of successful deployments, from small community gatherings to major international events and critical industrial infrastructure projects, demonstrating the adaptability and reliability of our crowd control barricades for sale.

Choosing Your Partner: Manufacturer Comparison and Quality Assurance

Selecting the right manufacturer for your crowd control barrier types is paramount. It's not just about the product itself, but the reliability, expertise, and support of your supplier. Here are key considerations when comparing manufacturers:

- Certifications and Standards Compliance: A reputable manufacturer will adhere to international quality management systems (e.g., ISO 9001:2015), demonstrating consistent quality. They should also meet specific product standards such as ASTM for materials or relevant national safety regulations.

- Material Quality & Traceability: Insist on manufacturers who use prime raw materials (like certified Q235 steel) and can provide material certificates, ensuring the integrity and durability of the finished product.

- Manufacturing Expertise: Look for evidence of advanced manufacturing processes (e.g., robotic welding, automated galvanization lines) and a skilled workforce. Experience in diverse applications, particularly challenging industrial ones, indicates a higher level of engineering capability.

- Customization Capabilities: The ability to offer custom dimensions, branding, specific finishes, or unique designs is a strong indicator of a flexible and client-focused manufacturer.

- Warranty and After-Sales Support: A strong warranty (e.g., 5-10 years on material and workmanship) and responsive customer support for inquiries, installation guidance, and troubleshooting are crucial for long-term satisfaction.

- Track Record and References: Look for companies with a long history (e.g., 10+ years in the industry), positive client testimonials, and a portfolio of successful projects, including collaborations with major events or industrial clients.

- Ethical and Sustainable Practices: A commitment to environmental responsibility and ethical labor practices reflects a reputable and trustworthy partner.

DQ Fence stands on a foundation of over 15 years of industry experience, specializing in high-quality fencing and barrier solutions. Our consistent investment in technology, adherence to ISO-certified processes, and a dedicated customer support team underline our commitment to excellence, providing reliable crowd barriers to clients worldwide. We pride ourselves on the authority we've built through decades of supplying durable and effective solutions.

Tailored Solutions: Customization and Design Services

Recognizing that every project has unique requirements, we offer comprehensive customization services for our crowd control barrier types. Whether you need specific dimensions, unique branding, or specialized functionality, our engineering and design teams work closely with clients to develop bespoke solutions. Our process typically involves:

- Initial Consultation: Understanding your specific needs, site conditions, crowd dynamics, and regulatory requirements.

- Design & Prototyping: Developing detailed CAD designs and, if necessary, creating prototypes for testing and approval. This can include integrating specific features such as wider feet for uneven terrain, custom heights, or specialized attachment points.

- Material & Finish Selection: Advising on the best materials and finishes (e.g., additional powder coating colors over galvanization) to meet durability and aesthetic needs.

- Branding Integration: Incorporating company logos, event names, or advertising panels directly into the barrier design or as attachable elements. This transforms functional barriers into valuable marketing assets for event organizers or brand promoters.

- Production & Quality Control: Manufacturing custom orders with the same rigorous quality control and inspection standards applied to our standard products.

This tailored approach ensures that clients receive crowd barriers that are perfectly suited to their application, maximizing effectiveness and return on investment. Our flexibility in delivering specific crowd control stanchions wholesale orders or large-scale customized barricades is a key differentiator.

Application Cases and Client Success Stories

Our crowd control barrier types have been deployed in a myriad of challenging and high-profile settings, proving their reliability and effectiveness:

- Case Study A: International Music Festival (2023, Europe): We supplied over 3,000 meters of hot-dip galvanized steel barricades for perimeter control, stage barriers, and VIP area segregation. The client reported "unprecedented ease of installation and dismantling, coupled with robust stability throughout the event, even with high crowd pressure." The barriers withstood variable weather conditions without any signs of rust or degradation, proving their long-term durability. This large-scale deployment required significant logistical coordination and rapid delivery, which our team executed flawlessly.

- Case Study B: Urban Infrastructure Project (2022, North America): For a major bridge renovation project in a densely populated urban area, we provided custom-height crowd barriers with integrated warning signage. These barriers effectively managed pedestrian and vehicular traffic around the construction zone for over 18 months. The project manager noted, "The durability of these barriers in a constant high-traffic, outdoor environment has been exceptional. We haven't had to replace a single unit due to rust or damage, saving us significant maintenance costs."

- Case Study C: Petrochemical Plant Expansion (2021, Middle East): Our specialized, corrosion-resistant galvanized crowd barriers were utilized to establish restricted access zones and create safe pathways within a new processing unit area. The barriers were exposed to harsh industrial chemicals and high temperatures. Client feedback highlighted the barriers' "superior resistance to chemical degradation and their ability to maintain structural integrity, crucial for safety compliance in our volatile environment."

These cases exemplify our commitment to providing solutions that not only meet but exceed client expectations in terms of performance, durability, and operational efficiency. The positive feedback and repeat business from our diverse client base reinforce our position as a trusted provider of quality crowd control barricades for sale.

Frequently Asked Questions (FAQ) about Crowd Control Barrier Types

Here are answers to some common professional questions regarding crowd control barrier types:

-

Q1: What are the primary material advantages of hot-dip galvanized steel for crowd control barriers?

A1: Hot-dip galvanized steel, typically Q235, offers superior corrosion resistance compared to other finishes. The zinc coating forms a metallurgical bond with the steel, creating a durable, self-healing barrier against rust, even if scratched. This significantly extends the lifespan of the barrier (15-20+ years), reduces maintenance, and ensures reliable performance in harsh outdoor or industrial environments (e.g., coastal areas, chemical facilities). -

Q2: How do your interlocking mechanisms enhance barrier stability and safety?

A2: Our barriers feature robust hook-and-eye or pin interlocking systems. These mechanisms create a continuous, rigid line when multiple barriers are connected, preventing individual units from being easily moved or toppled. This enhances overall stability, eliminates gaps for unauthorized entry, and creates a more secure perimeter, critical for effective crowd containment and safety. -

Q3: What quality control standards do your crowd control barriers adhere to during manufacturing?

A3: We adhere to stringent international quality standards, including ISO 9001:2015 for our manufacturing processes. Material quality (e.g., Q235 steel) is verified upon arrival. Post-welding, we conduct dimensional accuracy checks, and for galvanization, we ensure compliance with standards like ASTM A123/A123M for coating thickness and adhesion. Final inspections cover weld integrity, finish quality, and interlocking functionality. -

Q4: Can these barriers be customized for specific height requirements or branding?

A4: Yes, we offer comprehensive customization services. This includes adjusting barrier height and length, integrating custom logos or branding elements directly into the design, or providing specific color powder coatings over the galvanized finish. Our engineering team works with clients to meet unique dimensional, functional, or aesthetic requirements. -

Q5: What is the typical lifespan of a hot-dip galvanized crowd control barrier in outdoor conditions?

A5: Under normal outdoor conditions, a properly hot-dip galvanized crowd control barrier can have a service life of 15 to 20 years or more without significant corrosion. In less aggressive environments (e.g., dry, rural areas), it can last even longer. The thick zinc coating provides long-term protection against weathering and wear. -

Q6: Are your crowd barriers suitable for industrial applications like petrochemical or metallurgical plants?

A6: Absolutely. Due to their robust Q235 steel construction and superior hot-dip galvanization, our barriers offer excellent resistance to harsh industrial environments, including exposure to corrosive chemicals, high temperatures, and heavy impacts. They are ideal for demarcating safety zones, managing pedestrian/vehicular traffic, and securing perimeters in petrochemical, metallurgical, and water treatment facilities, where their durability and anti-corrosion properties are highly beneficial. -

Q7: What is the standard delivery lead time for a bulk order of crowd control barriers, and what warranty is provided?

A7: Standard delivery lead times for bulk orders typically range from 2 to 4 weeks, depending on order volume and customization requirements. We also offer expedited options for urgent projects. All our crowd control barrier types come with a limited warranty, usually 5 to 10 years, covering defects in materials and workmanship, ensuring peace of mind for our clients.

Delivery and Customer Support

Understanding the urgency often associated with crowd control needs, we strive for efficient order fulfillment and robust customer support. Our standard delivery lead times are typically 2-4 weeks for bulk orders of standard crowd barriers, with expedited options available upon request. We coordinate logistics to ensure timely and safe delivery to your specified location, anywhere in the world.

Beyond delivery, our commitment extends to comprehensive after-sales support. We provide a 5-10 year limited warranty on our crowd control barrier types, covering defects in materials and workmanship. Our dedicated customer service team is available via email, phone, and online portal to assist with installation guidance, maintenance tips, or any inquiries you may have, ensuring your investment continues to perform optimally for years to come.

Conclusion: Investing in Reliability and Safety

The choice of crowd control barrier types is a critical decision that impacts safety, operational efficiency, and long-term cost. As highlighted, the industry is moving towards more robust, versatile, and technologically integrated solutions. By understanding the manufacturing processes, technical specifications, and diverse application scenarios, organizations can make informed decisions when selecting their crowd management equipment. Investing in high-quality, hot-dip galvanized crowd barriers from a reputable manufacturer like DQ Fence means investing in durable, reliable solutions that stand the test of time and demand, ensuring optimal safety and control for any environment, from bustling public events to the most challenging industrial landscapes. Our product, available at https://www.dqfence.com/crowd-control-barrier.html, represents the pinnacle of this commitment to excellence.

Further Reading and Resources

- Grand View Research: Physical Security Market Analysis

- Mordor Intelligence: Physical Security Market - Industry Trends & Forecasts

- American Galvanizers Association: What is Hot-Dip Galvanizing?

- ASTM International: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025