- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Aug . 11, 2025 12:20 Back to list

Canada Temporary Fence & Fencing Solutions - Durable & Secure

Navigating the Canadian Market: Insights into Temporary Fencing Solutions

In Canada's rapidly expanding infrastructure, construction, and event sectors, the demand for robust and reliable temporary fencing solutions is paramount. A high-quality canada temporary fence is not merely a barrier; it's a critical safety component, a security perimeter, and a crowd control mechanism. Businesses, project managers, and event organizers rely on these systems to delineate boundaries, protect assets, and ensure public safety in dynamic environments. Understanding the nuances of these systems, from material specifications to deployment logistics, is essential for selecting the optimal solution that complies with local regulations and delivers long-term value. This detailed guide aims to equip B2B decision-makers with the knowledge needed to make informed procurement choices, ensuring their projects are secure and compliant with the stringent demands of the Canadian climate and operational needs.

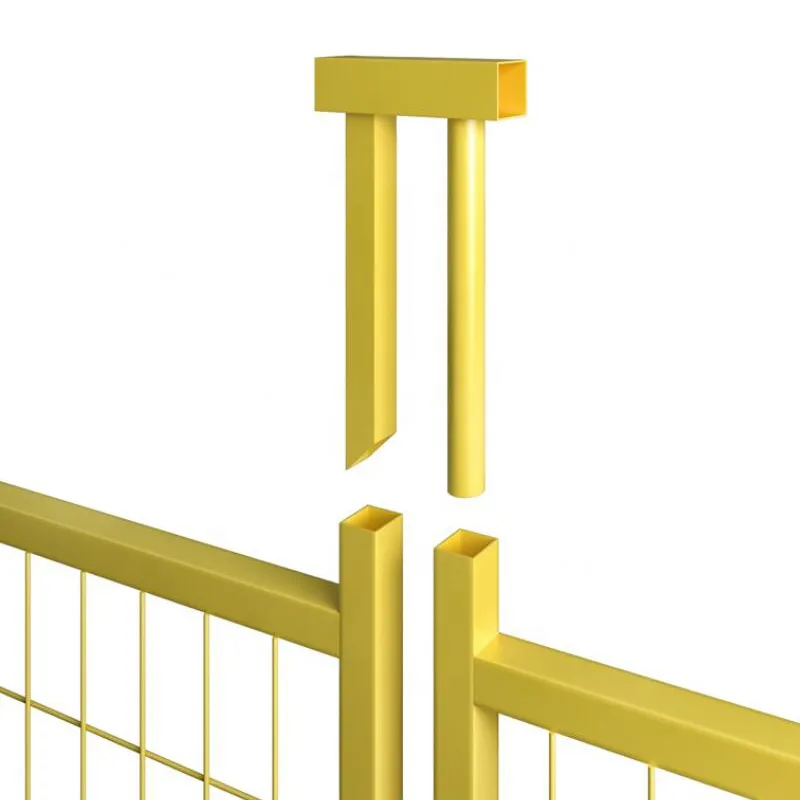

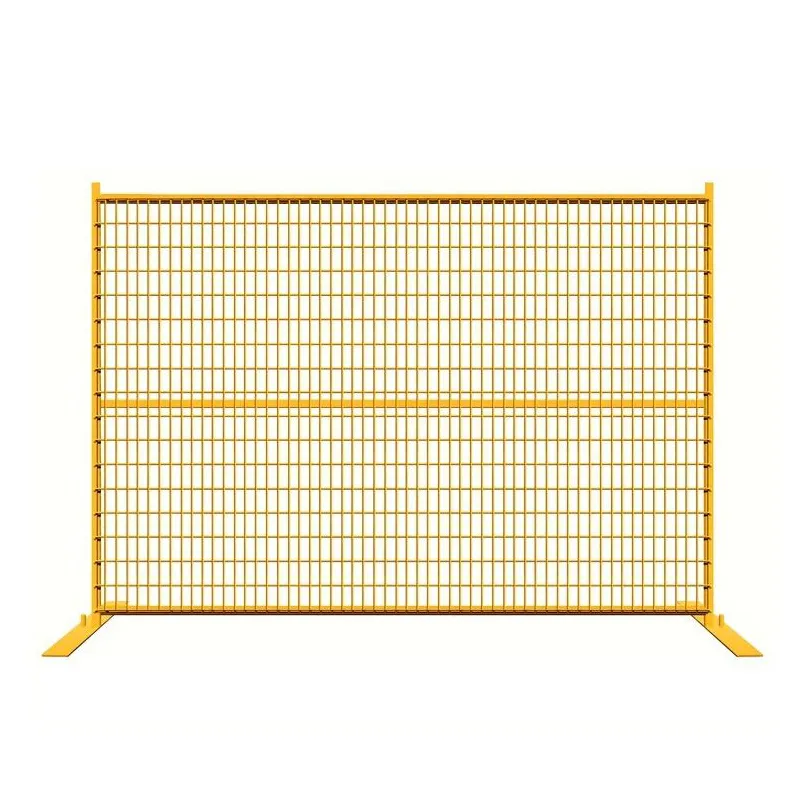

Canada Temporary Fence Panel: Technical Specifications at a Glance

The design and engineering of a canada temporary fence panel are crucial for its performance and longevity, particularly in Canada's diverse environmental conditions. Typically manufactured from high-grade galvanized steel, these panels are engineered to withstand harsh weather, provide significant impact resistance, and deter unauthorized access. Key specifications often include specific wire gauges for the infill mesh, robust pipe diameters for the frame, and advanced anti-climb designs to enhance security. Understanding these technical parameters is vital for assessing a fence's suitability for specific project requirements, ensuring it meets both performance expectations and industry standards like ASTM A123 for zinc coatings or CSA G164 for hot-dip galvanizing.

Standard Technical Parameters:

| Parameter | Specification |

|---|---|

| Panel Height | Typically 6 ft (1.83 m) or 8 ft (2.44 m) |

| Panel Length | Typically 9.5 ft (2.9 m) or 10 ft (3.05 m) |

| Frame Pipe Diameter | 32mm, 38mm, or 42mm (OD) |

| Frame Pipe Wall Thickness | 1.5mm to 2.0mm |

| Wire Mesh Gauge | 8 gauge (4mm) to 12 gauge (2.6mm) |

| Mesh Opening Size | 50x100mm, 60x150mm, or 75x150mm |

| Surface Treatment | Hot-dip galvanized (min. 42 microns zinc coating) or powder coated |

| Connection Type | Top couplers, base feet (concrete or plastic) |

These specifications ensure that a temporary fence canada is not only secure but also compliant with safety regulations for various applications, including construction sites, public events, and disaster zones. The choice of materials and dimensions directly impacts the fence's resistance to environmental factors and its ability to maintain structural integrity under stress.

Advanced Manufacturing: The Craftsmanship Behind a Resilient Temporary Fence

The superior performance of a temporary fencing canada solution stems from a meticulous manufacturing process. It begins with the selection of high-tensile, low-carbon steel, chosen for its strength and ductility. The process typically involves several critical stages, each contributing to the final product's durability and functionality.

- Material Preparation: High-quality steel wires and pipes are cut to precise lengths using automated machinery, ensuring consistency and minimizing material waste.

- Mesh Welding: The infill mesh is formed by resistance welding individual vertical and horizontal wires at each intersection. This creates a strong, rigid panel with uniform mesh openings, crucial for preventing climbing and maintaining structural integrity.

- Frame Fabrication: Steel pipes are precisely bent and welded to form the rectangular frame. Corner reinforcement is often incorporated to enhance rigidity. The integrity of these welds is paramount; advanced welding techniques like MIG (Metal Inert Gas) welding ensure strong, consistent joints that can withstand significant stress.

- Surface Treatment – Hot-Dip Galvanization: This is a cornerstone of corrosion protection for any outdoor steel product, especially a construction fence canada. After fabrication, panels are thoroughly cleaned and then immersed in a bath of molten zinc at approximately 450°C (840°F). This process creates a metallurgically bonded zinc coating that provides superior sacrificial and barrier protection against rust and abrasion. The coating thickness is rigorously tested to meet or exceed international standards like ISO 1461 and ASTM A123.

- Optional Powder Coating: For enhanced aesthetics and additional corrosion resistance, some panels undergo an electrostatic powder coating process after galvanization. This adds a durable polymer layer available in various colors, ideal for event fencing or corporate branding.

- Quality Inspection: Throughout the process, strict quality control protocols are implemented. This includes dimensional checks, weld integrity tests, coating thickness measurements, and visual inspections to ensure every panel meets stringent internal and external standards. Products are often certified to ISO 9001 for quality management systems.

This meticulous process ensures a prolonged service life, typically 10-15 years for hot-dip galvanized panels, even in demanding environments common to construction, public infrastructure, and petrochemical sectors. The anti-corrosion properties significantly reduce maintenance costs and ensure long-term reliability.

Technical Advantages and Features of a Robust Temporary Fence

Investing in a high-quality portable fence canada solution offers several distinct advantages that contribute to project efficiency, safety, and cost-effectiveness. These benefits extend beyond mere physical separation, encompassing practical features that enhance usability and performance in diverse settings.

- Superior Durability: Constructed from galvanized steel, these fences resist rust, corrosion, and material degradation, ensuring they remain structurally sound through repeated use and exposure to harsh Canadian weather, including snow, ice, and strong winds.

- Enhanced Security: The small mesh openings (anti-climb design) and robust frame deter unauthorized entry and prevent items from being easily passed through. Combined with sturdy base feet and top couplers, they form a formidable barrier for site security.

- Ease of Installation and Portability: Designed for rapid deployment and dismantling, temporary fence panels feature a modular system that requires no digging or complex tools. This significantly reduces labor costs and setup time, making them highly efficient for short-term projects or dynamic site requirements. Their lightweight yet strong design ensures easy transport and repositioning.

- Versatility and Adaptability: Compatible with various accessories like bracing systems for added wind stability, privacy screens, pedestrian gates, and vehicle gates, these fences can be tailored to specific site needs. This adaptability makes them suitable for everything from small construction zones to large-scale public events.

- Cost-Effectiveness and Reusability: Their exceptional lifespan and ability to be quickly relocated and re-erected across multiple projects translate into significant long-term savings. High-quality panels maintain their integrity and appearance, reducing the need for frequent replacements and minimizing environmental impact.

These technical advantages underscore why a well-manufactured canada temporary fence is a superior choice for safety and operational efficiency, providing a reliable perimeter solution for critical operations.

Diverse Application Scenarios: Where Temporary Fences Excel

The versatility of a canada temporary fence makes it indispensable across a wide array of industries and applications. Its modular nature allows for quick adaptation to changing site conditions, providing flexible yet secure perimeters.

- Construction Sites: This is arguably the most common application for construction fence canada. They are vital for securing active construction zones, preventing unauthorized access, protecting the public from potential hazards, and containing debris. They can be easily relocated as phases of a project are completed, adapting to evolving site layouts.

- Event Management: From concerts and festivals to sporting events and trade shows, temporary fencing canada is crucial for crowd control, directing pedestrian flow, securing VIP areas, and managing entry/exit points. Its quick setup and dismantle times are highly valued in the fast-paced event industry.

- Public Works and Utilities: During road repairs, utility installations, or infrastructure upgrades, these fences create safe working zones and protect the public from excavations and heavy machinery. They are essential for temporary traffic management and site safety.

- Emergency and Disaster Relief: In times of natural disasters or other emergencies, portable fence canada can quickly establish temporary perimeters for safety, delineate hazardous areas, or secure relief efforts, providing essential order and protection.

- Industrial and Commercial Security: Businesses often use temporary fences for short-term security enhancements, temporary warehouse division, or managing pedestrian and vehicle traffic within large industrial complexes, ensuring controlled access and operational safety.

In each of these scenarios, the ability to rapidly deploy a sturdy, compliant, and re-locatable fencing solution provides immense value, ensuring safety and operational continuity while meeting stringent Canadian requirements.

Manufacturer Comparison & Tailored Solutions: Choosing Your Partner

When sourcing a temporary fence canada, comparing manufacturers goes beyond just price. Key differentiators include material quality, manufacturing precision, adherence to international standards, and the ability to provide customized solutions. A reputable manufacturer will possess certifications like ISO 9001 for quality management and have a proven track record of supplying durable products that meet Canadian safety regulations, ensuring consistent performance.

Customization options are critical for unique project requirements. This includes variations in panel height and length, specific mesh configurations (e.g., smaller apertures for enhanced anti-climb features), specialized gates (swing gates, sliding gates), and bespoke color powder coating to match corporate branding or aesthetic needs. A knowledgeable supplier can also advise on optimal bracing systems for high-wind areas or specific ground conditions, ensuring maximum stability and compliance with local engineering requirements. For instance, projects requiring extended anti-corrosion life in coastal regions might benefit from a duplex coating system (galvanization followed by powder coating) for unparalleled protection, a solution only offered by experienced providers.

Beyond product specifications, evaluate a manufacturer's customer support, lead times, and logistical capabilities for delivery across Canada. Partnering with a specialist ensures not only a superior product but also seamless project execution from order to installation, minimizing potential delays and operational disruptions.

Enhancing Trust: Quality Assurance, Warranty & Client Support

For B2B buyers, trust is built on verifiable quality, reliable service, and transparent commitments. A leading supplier of canada temporary fence solutions demonstrates this through stringent quality assurance protocols, comprehensive warranties, and proactive customer support, ensuring peace of mind for their clients.

- Certifications and Standards: Look for manufacturers holding ISO 9001:2015 certification for quality management, signifying a commitment to consistent product quality. Adherence to specific material standards like ASTM F2453 (for welded wire fence fabric) or Canadian-specific building codes for temporary structures further underlines their authority. Many reputable suppliers conduct independent third-party testing on their products to validate performance claims, such as wind load resistance or coating adherence.

- Warranty and Longevity: A strong warranty, typically 10-15 years for hot-dip galvanized finishes against corrosion, reflects the manufacturer's confidence in their product's durability. This commitment translates directly into lower lifecycle costs for the buyer, eliminating the need for frequent replacements and providing excellent return on investment.

- Client Feedback and Case Studies: While specific client names may be confidential, a reputable company can share anonymized case studies or general feedback demonstrating successful deployments in various Canadian provinces, highlighting complex installations or large-scale projects where their portable fence canada systems excelled.

- Delivery & Logistics: Clear communication regarding lead times and efficient logistics are crucial. A reliable supplier will provide accurate delivery schedules and potentially offer expedited shipping options for urgent requirements. Their experience in navigating Canadian shipping lanes and customs processes is also a significant advantage for timely project completion.

- Post-Sale Support: Comprehensive customer support, including technical advice on installation, maintenance guidelines, and responsive assistance for any inquiries or issues, reinforces trustworthiness and ensures optimal product performance throughout its lifespan.

These elements collectively assure buyers of a dependable product and a trustworthy partnership, critical for large-scale procurement and long-term project planning in any industrial or commercial sector.

Frequently Asked Questions (FAQs)

- Q1: What is the typical lifespan of a hot-dip galvanized canada temporary fence panel?

- A1: Hot-dip galvanized panels typically have a service life of 10-15 years, or even longer in less corrosive environments, due to the robust zinc coating providing excellent protection against rust and corrosion, significantly extending the product's usability.

- Q2: Are your temporary fences compliant with Canadian safety standards?

- A2: Yes, our temporary fence panels are manufactured to meet or exceed relevant international standards like ISO 1461 for galvanization and are designed to comply with general safety and perimeter security requirements prevalent in Canada for construction and event sites, ensuring broad applicability.

- Q3: Can these fences be customized for specific project needs?

- A3: Absolutely. We offer extensive customization options including varying panel dimensions, mesh configurations (e.g., smaller aperture anti-climb mesh), specialized gate designs (pedestrian, vehicle), and custom powder coating colors to match branding or specific aesthetic requirements of your project.

- Q4: What types of bases are available for temporary fence panels?

- A4: Common base types include concrete blocks, blow-molded plastic feet (often filled with water or sand for stability), and steel base plates. The choice depends on ground conditions, stability requirements, and ease of relocation for optimal setup.

- Q5: How quickly can I get a large order delivered in Canada?

- A5: Delivery times depend on the order volume, current stock levels, and specific destination within Canada. We strive for efficient logistics and will provide a clear, estimated delivery schedule upon quotation. Expedited options may be available for urgent requirements, catering to tight project deadlines.

Authoritative References

- ASTM International. ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. West Conshohocken, PA: ASTM International, 2017.

- International Organization for Standardization. ISO 9001:2015: Quality management systems – Requirements. Geneva, Switzerland: ISO, 2015.

- CSA Group. CSA G164: Hot-dip Galvanizing of Irregularly Shaped Articles. Toronto, ON: CSA Group, latest edition.

- National Research Council Canada. National Building Code of Canada 2020. Ottawa, ON: National Research Council Canada, 2020.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025