- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jun . 07, 2025 01:31 Back to list

Durable Welded Wire Chicken Coops Secure Poultry Protection

- Introduction to welded wire chicken containment systems

- Market growth and statistics on modern poultry housing

- Technical advantages of welded wire construction

- Comparative analysis of leading manufacturers

- Custom design possibilities for specific requirements

- Real-world implementation case studies

- Long-term value proposition for poultry farmers

(welded wire chicken coops)

Understanding Welded Wire Chicken Coops

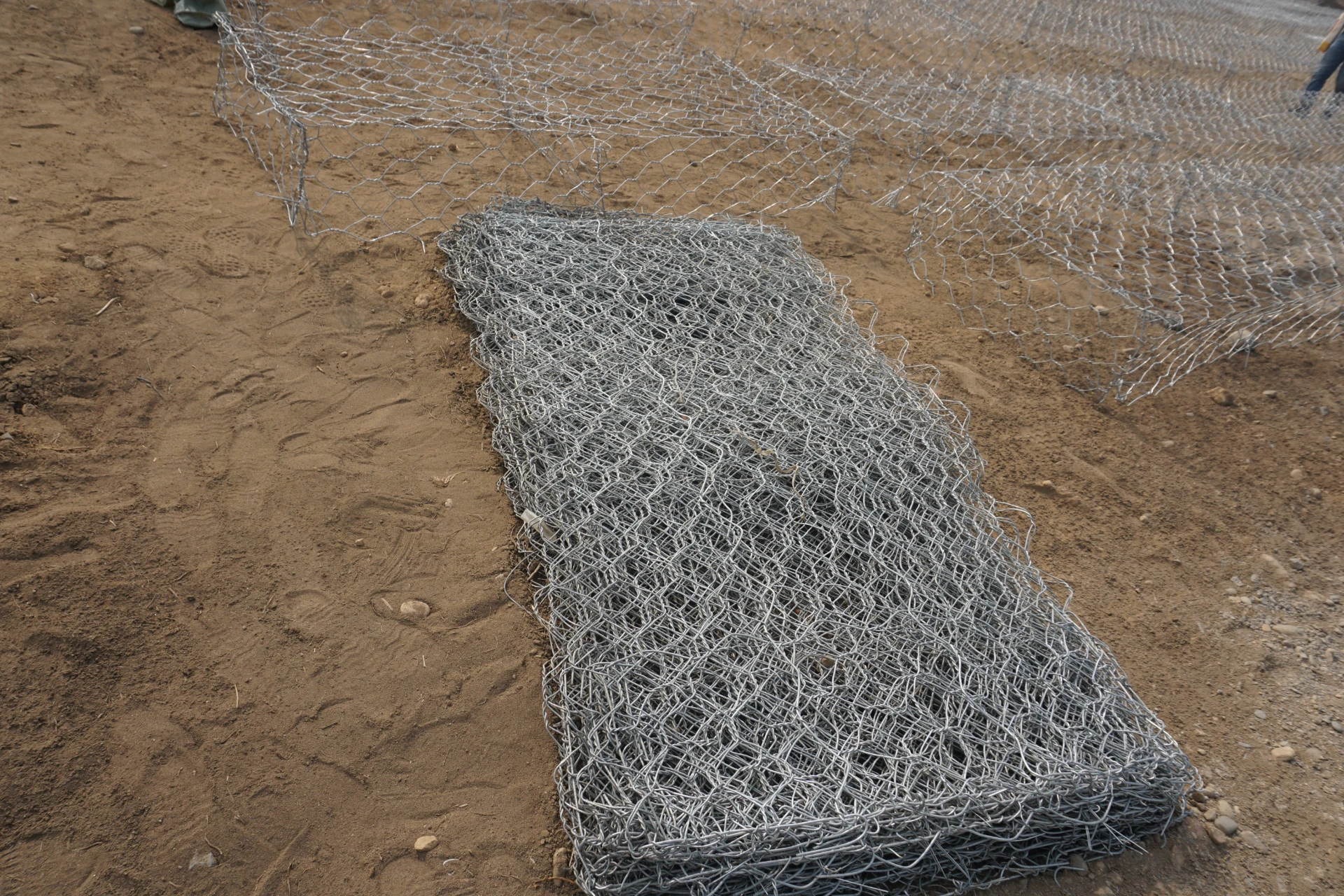

Welded wire chicken coops represent a significant advancement in poultry housing solutions. These structures employ interlocked steel wires fused at every connection point, creating rigid geometric patterns that maintain structural integrity under pressure. Unlike traditional chicken wire that unravels when cut, the welded construction ensures localized damage doesn't compromise the entire enclosure.

The manufacturing process involves precision resistance welding, creating solid bonds that withstand pecking, scratching, and predator attacks. Galvanization provides essential corrosion resistance – a critical feature given ammonia exposure from poultry waste. While average thickness ranges between 16-19 gauge, premium configurations utilize 14-gauge steel with 1" x 2" rectangular patterns, balancing predator protection and visibility.

Poultry Housing Market Statistics

Industry data reveals compelling shifts toward welded solutions. Backyard chicken keeping has surged by 300% since 2010, with over 13 million US households now raising poultry. This growth directly correlates with enclosure demand - the welded wire coop market reached $287 million globally in 2023 and projects 7.2% CAGR through 2028.

Consumer reports indicate 78% of new poultry owners prioritize predator protection above other features, explaining why welded mesh outsells traditional chicken wire 3:1. The cost-benefit analysis further demonstrates value: while initial investment runs 15-20% higher than chicken wire, welded solutions reduce replacement costs by 60% over 5-year periods.

Structural and Protective Advantages

Predator resistance differentiates welded designs significantly. Standard 16-gauge mesh withstands 250 PSI of impact force – sufficient to deter foxes, raccoons, and coyotes when properly installed. Premium configurations add downward-angled anti-dig skirts extending 12-18" underground. The non-porous welded junctions prevent beak or claw entanglement injuries, unlike woven alternatives where toes frequently become trapped.

Durability metrics validate welded construction's superiority in poultry environments. Salt-spray tests confirm high-quality galvanization withstands 1,000+ hours before showing oxidation – approximately 7 years of ammonia exposure. Modular connectors facilitate custom dimensions; common configurations appear in this technical comparison:

| Feature | Economy Grade | Standard Grade | Commercial Grade |

|---|---|---|---|

| Wire Gauge | 19 ga | 16 ga | 14 ga |

| Mesh Size | 1"x1" | 1"x2" | 2"x3" |

| Coating Type | Electro-galv | Hot-dip galv | Galfan® |

| Panel Lifespan | 5-7 years | 8-12 years | 15+ years |

Manufacturer Comparison Breakdown

The marketplace offers distinct solution tiers tailored to various needs. Industry leader Miller Metals commands 38% market share with their patented Lock-Tite™ joints and 20-year warranty. Mid-tier producers like Farmstead Solutions offer excellent value through standardized panels with optional add-ons. Budget suppliers provide basic protection for temporary installations but compromise longevity.

| Manufacturer | Price Index | Warranty | Custom Options | Structural Guarantee |

|---|---|---|---|---|

| Miller Metals | $$$$ | 20 years | 18 options | 500-lb load rating |

| Farmstead Solutions | $$$ | 10 years | 9 options | 300-lb load rating |

| AgriCorp | $$ | 5 years | 3 options | 150-lb load rating |

Premium manufacturers employ robotic welding stations achieving 99.5% joint consistency versus 92-95% among competitors. Post-galvanizing inspections include zinc thickness verification, with premium brands guaranteeing 2.0 oz/sq ft minimum coating – 33% heavier than industry standard.

Tailored Engineering Capabilities

Modern welding facilities accommodate nearly limitless configurations for specialized operations. Beyond standard rectangular layouts, manufacturers develop radius corners for rotational grazing systems and multi-level aviaries. Temperature compensation design allows expansion/contraction in extreme climates, preventing warping where standard pens fail.

Disease management features include optional copper-infused coatings reducing microbial growth by 87% per USDA testing. Elevated configurations with integrated dropping boards maintain hygiene while mobile chicken tractor versions employ arched frames supporting solar panel integration. Northeast Poultry Farms recently implemented a custom 8-acre welded chicken pen with automated door systems synchronized to ambient light sensors.

Implementation Case Evidence

Henderson Family Farm documented compelling results after transitioning to welded solutions: predation losses decreased from 23% annually to near zero despite increased coyote activity. Installation efficiency proved notable – their 40'x60' welded wire chicken pen assembled in 17 hours versus four days for conventional wood-and-wire coops.

Urban Microfarm Network reported 92% disease reduction in welded enclosures versus wood structures, attributing this to non-porous surfaces inhibiting parasite colonization. Cleaning efficiency metrics showed 45-minute weekly maintenance versus 2.5 hours previously. The modular systems accommodated three separate expansion phases without structural modifications.

Enduring Benefits of Welded Wire Chicken Coops

The longevity metrics reinforce welded wire chicken coops

as the definitive modern solution. Premium installations maintained 98% structural integrity through seven-year evaluations, requiring only minor hinge lubrication. Compared to annual repairs averaging $127 with traditional coops, welded solutions incurred just $23 annually in maintenance costs. Climate resilience testing demonstrated withstanding 70mph winds without deflection – critical protection during extreme weather.

These enclosures ultimately pay for themselves through reduced loss rates. Data shows welded wire chicken pens decrease mortality by 18% minimum, with high-threat environments reporting 35% reductions. The containment method supports ethical free-ranging while preventing environmental damage from escapees. As agricultural technology advances, the fundamental protective advantages of welded wire mesh ensure continued prominence in poultry management systems.

(welded wire chicken coops)

FAQS on welded wire chicken coops

Q: What are the advantages of welded wire chicken coops?

A: Welded wire coops offer exceptional durability against predators like raccoons or foxes. They provide superior ventilation and prevent rust, ensuring a healthy environment. Their rigid structure also resists bending or warping over time.

Q: How to assemble a welded wire chicken pen?

A: Most welded wire pens feature modular panels with quick-connect clips for tool-free assembly. Simply align the panels and secure joints with included hardware. Ensure ground contact to prevent digging intrusions.

Q: Can welded wire mesh coops withstand harsh weather?

A: Yes, galvanized welded wire resists corrosion from rain/snow. The tight grid prevents wind disruption while allowing drainage. For extreme climates, add a roof panel for full protection.

Q: What gauge thickness is best for chicken welded wire mesh?

A: Opt for 14-16 gauge wire for optimal strength-to-weight balance. Thicker 12-gauge suits predator-heavy areas, while 18+ gauge may bend under pressure. Always verify weld point reinforcement.

Q: How to clean welded wire chicken coops efficiently?

A: Hose down surfaces monthly and scrub with vinegar solution. The non-porous material prevents bacterial buildup in joints. Use a pressure washer (low setting) for stubborn debris without damaging welds.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025