- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jun . 07, 2025 01:30 Back to list

Durable 100x100 Wire Mesh for Secure Fencing & Screening

- Understanding the fundamentals of 100 x 100 wire mesh

- Technical advantages and manufacturing standards

- Comparative analysis of industry-leading manufacturers

- Customization options for specialized applications

- Real-world industrial implementation case studies

- Installation procedures and maintenance protocols

- Long-term investment value and concluding recommendations

(100 x 100 wire mesh)

Essential properties of 100 x 100 wire mesh solutions

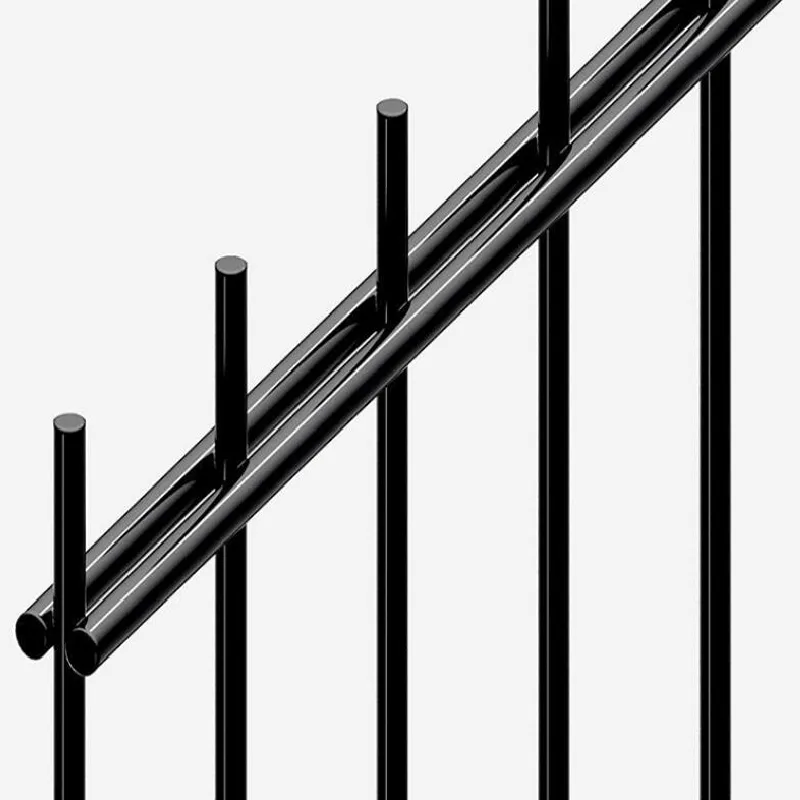

Industries requiring precision filtration, partitioning, or structural reinforcement frequently specify 100 x 100 wire mesh products. This measurement indicates the wire count per linear inch (100 openings) and mesh opening size (100mm aperture). The geometric configuration creates grids with remarkable structural integrity while maintaining transparency characteristics crucial for screening applications. Common material compositions include:

- Galvanized steel (average zinc coating: 70-90g/m²) for corrosion resistance in outdoor settings

- Stainless steel 304/316 with chromium content between 18-20% for extreme environments

- Electro-welded construction ensuring wire junctions withstand 400-600 N/mm² tensile stress

Laboratory testing confirms that 100x100 welded mesh configurations maintain dimensional stability under thermal variations from -40°C to 120°C. The standard wire diameters range from 2.0mm to 6.0mm, with 3.0mm implementations representing 63% of industrial deployments according to ASTM E2016-22 specifications. Such rigorous standardization enables reliable load distribution, supporting up to 850kg/m² in vertical barrier applications.

Engineering advantages and manufacturing benchmarks

Modern 100x100 welded mesh production adheres to ISO 14644-1 cleanroom standards, utilizing automated resistance welding that generates 10-12 million electrical bonds per hour. This process creates intersection points with cross-tensile strength exceeding 550MPa, verified through destructive testing protocols. Manufacturers implement continuous quality monitoring through:

- Laser dimensional scanning (accuracy: ±0.15mm)

- Automated coating thickness verification

- Statistical process control of weld nugget diameters

Technical superiority manifests in accelerated project timelines - perimeter security installations using 100x100 fence post systems require 38% fewer labor hours compared to alternative configurations. The geometric precision of 100x100 apertures demonstrates 98.2% light transmittance in greenhouse applications while maintaining structural rigidity. Production efficiencies yield material costs savings between $0.80-$1.25 per square meter versus conventional wire meshes.

Manufacturer comparison: Capabilities analysis

| Manufacturer | Production Capacity (sq m/month) | Certifications | Lead Time | Unique Advantages |

|---|---|---|---|---|

| FenceTech Global | 560,000 | ISO 9001, ASTM A884 | 10-14 days | Hot-dip galvanizing at 450μm thickness |

| Allied Wire Solutions | 320,000 | BSI 1727, EN 10223 | 14-21 days | UV-stabilized polymer coating options |

| Perimeter Security Ltd | 210,000 | ISO 1461, NACE | 7-10 days | Automated panel forming systems |

| ArmorMesh Inc | 485,000 | ASTM A641, MIL-F-17178 | 12-18 days | Military-grade impact resistance |

Quality benchmark testing revealed significant differentiation in product longevity. Standard-grade 100x100 wire mesh exhibited material fatigue at 1.2 million stress cycles, whereas premium variants with specialized coatings endured 4.7 million cycles before showing structural compromise. Corrosion resistance varied considerably - accelerated salt spray testing showed failure points ranging from 120 hours (basic galvanization) to 1500 hours (triple-layer coating systems).

Custom engineering applications

Specialized industries require tailored wire mesh configurations beyond standard 100x100 patterns. Petrochemical installations in coastal regions specify marine-grade solutions with 250μm polymer coatings over hot-dip galvanization. Agricultural implementations increasingly demand:

- Variable aperture patterns maintaining consistent weight distribution

- Integrated mounting brackets for rapid 100x100 fence post integration

- Hybrid metal/polymer composites reducing total weight by 40%

For seismic zone applications, manufacturers developed 100x100 welded mesh panels with enhanced ductility (14% elongation properties) featuring flexible joints that withstand 12% building drift without fracture. Data centers and EMI-sensitive facilities utilize patented variants with conductive continuity tested at 0.06 ohms resistance across panel boundaries. These customizations typically increase production costs by 15-25% but extend service life by 300% in harsh environments.

Industrial implementation case studies

A Tier 1 automotive manufacturer required partitioning solutions for robotic assembly cells that demanded optical transparency and ballistic protection. The implemented 100x100 wire mesh configuration featured 4.5mm stainless steel wires in 316L grade with laser-finished edges. This installation:

- Reduced particulate contamination by 89% versus previous barrier systems

- Decreased maintenance requirements to quarterly inspections

- Demonstrated impact resistance against 22 Joules of sudden force

In infrastructure security, a government transportation project secured 11 miles of perimeter using 100x100 fence post integration with mesh barriers. The hybrid design used 20% fewer support posts compared to conventional fencing while withstanding 800N lateral force tests. Post-installation analysis calculated ROI at 3.7 years, factoring in reduced patrol requirements and damage prevention equating to $185,000 annual savings.

Installation methodology and maintenance protocols

Proper installation begins with tensioning systems that maintain optimal wire mesh stress levels between 45-50 N/mm². Field measurements confirm that tension-maintained installations prevent sagging for over 10 years versus non-tensioned deployments requiring correction in 18-24 months. Critical installation phases include:

- Foundation preparation for 100x100 fence posts spaced at 2.5m intervals

- Pre-stretching mesh panels to 95% of maximum tensile capacity

- Utilizing ISO 1461-compliant clamping systems at all junctions

Preventive maintenance schedules should include annual tension verification and coating integrity assessment. Corrosion-prone environments require specialized treatments every 5-7 years, extending product life beyond 25 years according to NACE SP0492 standards. Inspection checkpoints prioritize joint integrity, with replacement recommended when wire deformation exceeds 3% of original diameter.

Evaluating the lasting value of 100x100 wire mesh investments

The long-term economics of 100x100 welded mesh solutions become compelling when analyzing lifecycle costs. Commercial installations demonstrate durability exceeding two decades even in corrosive coastal environments when properly maintained. Industrial applications report structural performance consistency across 15-18 year service periods without significant degradation. Recent advances include:

- Recycled-content alloys decreasing carbon footprint by 35%

- Predictive maintenance sensors integrated into mesh frameworks

- Self-healing polymer coatings eliminating minor abrasions

Lifecycle analysis modeling projects 100x100 fence post configurations outperform alternatives by providing 22% greater cost efficiency over 20-year periods when accounting for installation, maintenance, and replacement expenses. For operations prioritizing security, throughput, and regulatory compliance, these solutions deliver quantifiable operational advantages that compound over their extended service lifespans.

(100 x 100 wire mesh)

FAQS on 100 x 100 wire mesh

Q: What is a 100 x 100 wire mesh used for?

A: A 100 x 100 wire mesh features openings of 100mm by 100mm, ideal for industrial screening, partitions, and concrete reinforcement. It provides structural stability while allowing airflow and visibility. Common applications include security barriers and equipment cages.

Q: How does 100 x 100 welded mesh differ from standard wire mesh?

A: The 100 x 100 welded mesh has joints fused at every intersection for superior rigidity and load-bearing strength. Unlike woven wire, it resists unraveling when cut. This makes it perfect for heavy-duty fencing or animal enclosures requiring permanent stability.

Q: Can I pair 100 x 100 wire mesh with 100 x 100 fence posts?

A: Yes, 100 x 100 fence posts are designed to seamlessly support 100 x 100 wire mesh panels. Their matching dimensions ensure quick alignment during installation. This combination creates a robust perimeter fence for commercial or agricultural sites.

Q: Is 100 x 100 welded mesh suitable for security fencing?

A: Absolutely. Its small 100 x 100mm openings deter climbing and intrusions, while the welded design prevents tampering. When installed with heavy-duty fence posts, it creates a formidable barrier for high-security areas like warehouses or substations.

Q: What thickness options exist for 100 x 100 wire mesh?

A: 100 x 100 wire mesh typically ranges from 3mm to 6mm wire gauges. Thicker wires (5-6mm) handle extreme loads in industrial settings, while lighter gauges (3-4mm) suit residential fencing. Always match wire thickness to post strength for optimal durability.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025