- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jul . 29, 2025 13:00 Back to list

Canada Temporary Fence - Durable & Easy Installation Solutions

In recent years, the canada temporary fence market has exhibited significant growth, driven by rising infrastructure projects, enhanced safety regulations, and a surge in urban development across Canada. According to Canadian Building Magazine (2023), the temporary fence canada sector is anticipated to achieve a CAGR of 4.3% from 2023 through 2027, with construction fence canada solutions accounting for nearly 55% market share.

The demand for portable fence canada and temporary fencing canada is also increasing in events, public works, mining, and pipeline projects, primarily due to flexibility, ease of installation, and compliance with safety standards such as ISO 9001:2015 and ANSI A10.18.

| Year | Total Market Size ($Million) | Major Segment Share (%) | Growth Rate (%) | Key Application Sectors |

|---|---|---|---|---|

| 2022 | 405 | Construction: 53 Events: 19 Mining: 9 | 4.1 | Construction, Event Security, Industrial |

| 2023 | 422 | Construction: 55 Events: 20 Mining: 8 | 4.3 | Construction, Municipal, Oil&Gas |

| 2024 (est.) | 441 | Construction: 56 Events: 21 Mining: 7 | 4.5 | Construction, Infrastructure, Utilities |

- Stringent safety compliance (ISO 9001, ANSI, CSA national standards)

- Demand for quick, modular, reusable barriers

- Sustainable, anti-corrosion engineered products for harsh climates

- Increasing preference for temporary fencing canada in event management & policing

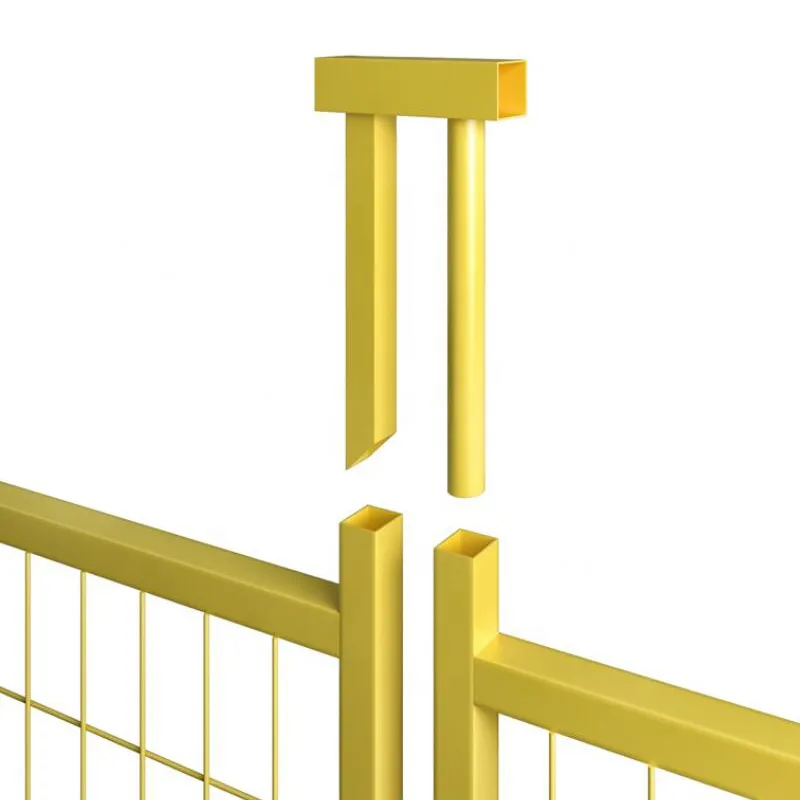

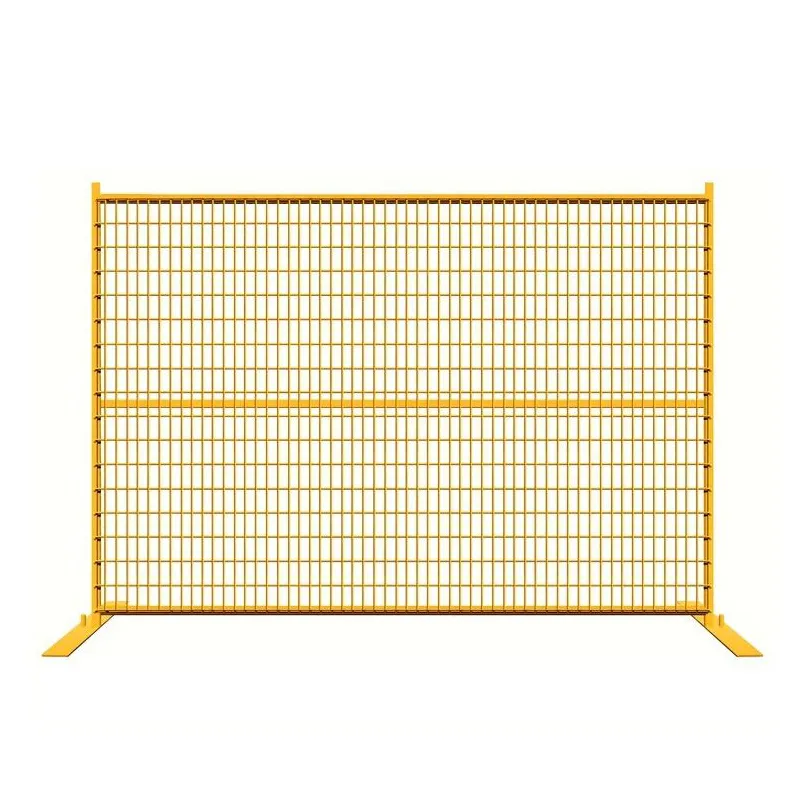

Canada Temporary Fence Panel (More details here) is designed to meet the toughest project requirements for site security and demarcation. Manufactured from high-quality galvanized steel, these panels deliver exceptional strength, weather resistance, and anti-corrosion performance, making them ideal for Canadian climates and rigorous standards.

- Structure: Modular welded mesh panel, reinforced tubular frame (32mm or 38mm OD tubes, 1.5–2mm wall thickness)

- Surface: Hot-dip galvanized (zinc layer ≥ 42–75 μm); galvanized + polyester powder coating optional for color & enhanced durability

- Panel Size: 6ft x 10ft (1.8m x 3.0m) / 6ft x 9.5ft standard; custom sizes available

- Mesh Size: 60 x 150mm / 50 x 100mm

- Service Life: ≥ 8 years (industry avg. 4–6 years)

- Compliance: ISO, ANSI, CSA, OSHA standards

- Applications: Construction, civil engineering, events, power, mining, oil/gas, emergency response

| Parameter | Specification | Typical Value | Industry Standard |

|---|---|---|---|

| Main Material | Q235/Hot-dip galvanized steel | ASTM A36/Q235 | ISO 9001, CSA A23.1 |

| Frame Tube OD | 32-38 mm | 32 mm/38 mm | ANSI A10.18 |

| Mesh Size | 60x150 mm | 60x150 mm | CSA, ISO grid |

| Zinc Layer Thickness | ≥42 μm | 60–75 μm | ISO 1461 |

| Panel Height | 1.8 m / 2.0 m | 1.8 m | Industry standard |

| Anti-corrosion Test | Salt spray, 500h | No red rust | GB/T 10125 |

| Welding Method | MIG automatic | Full weld | ISO 3834 |

| Service Life | 6–10 years | 8+ years | OEM standard |

High-grade steel pipes & wires selection

MIG robotic/craftsmanship weld mesh & frame

Full zinc immersion (ISO 1461)

Salt spray, weld, size, load test

Eco-protective wrap, logistics

- Material: ASTM/CSA-certified low-carbon steel; high-grade Q235 to guarantee strength and plasticity.

- Galvanization: Hot-dip zinc–coated, ISO 1461: Salt spray resistant (≥ 500h), Zinc layer avg. 60 μm, field-tested for urban/rural climates.

- Welding: Full welding by automatic CNC, ISO3834/ANSI A10.18 certified, min. 20 spot welds per 2m length.

- Inspection: Visual, mechanical load, mesh aperture verification & formal anti-corrosion test as per GB/T 10125.

- Features: Excellent structural strength, long lifespan, customizable branding (colors/logos), environmental eco-friendly process.

| Company | Main Product Lines | Certifications | Delivery Time | Custom Options | Major Clients |

|---|---|---|---|---|---|

| DQFENCE | Canada Temporary Fence Panel, Construction Fence Canada | ISO 9001, CSA, ANSI | 10–15 days | Color/logo, mesh & frame spec, foot blocks, security accessories | EllisDon, Aecon, SNC-Lavalin |

| Modu-Loc | Temporary Fencing Canada, Event Fences | ISO 9001, COR | 6–14 days | Branding, gate integration, fence screening | PCL, Graham Construction, LMG |

| National Construction Rentals | Construction Fence, Portable Fence Canada | CSA, OSHA | 12–18 days | Panel size, mesh gauge, accessories | Lafarge, EllisDon |

- Panel size, shape and mesh aperture customizations to fit site plans

- Corporate branding/colors, project panel serial coding, unique gate modules

- Custom feet/base blocks: anti-tripping and weighted (options: orange concrete, eco-plastic, steel block)

- Smart surveillance upgrade: RFID or QR-code tagging, asset management available

- Product: Canada Temporary Fence Panel, 1,200 panels, 2.0m height, orange feet, integrated safety screening

- Result: Zero safety incident in 14 months, vandal resistance proved, no corrosion/fade after 2 winters

- Feedback: "Fastest setup in the project, no downtime during snow, panel remains pristine." — Site Supervisor, EllisDon

- Scenario: Outdoor music festival, 8,000+ attendees

- Product: temporary fencing canada, 900 panels, custom graphics, block base

- Advantage: Installed 45% faster than traditional wooden barriers, no base movement; event organizers rated panel "best in class" for security and branding.

- Challenge: Harsh conditions (extreme cold, wind-blown grit)

- Solution: Galvanized construction fence canada with reinforced mesh and anti-lift features

- Outcome: 99%+ uptime; passed annual ISO/ANSI safety audits

- Major civil/infrastructure projects (roads, airports, subway sites)

- Resource extraction (oil, gas, pipelines, mining platforms)

- Large events (marathons, concerts, parades, trade shows)

- Municipal environments (parks, emergency cordons, crowd control)

- Quality Promise: All Canada Temporary Fence panels delivered with full inspection records; 99% defect-free delivery (tested, certified)

- Certifications: ISO 9001:2015, CSA A23.1, ISO1461, ANSI/OSHA

- Shipment Cycle: Standard 10–15 business days, fast-track available

- Warranty: Minimum 36-month product warranty; annual maintenance/advice included

- Customer Service: Response within 8 hours, project design consultation, on-site setup guidance available

- Support: 24/7 hotline (English/French), spare parts free in warranty period

- Stringent Quality Control: 100% panels inspected, with batch records traceable to material source and production date

- Professional Team: Engineers with 10+ years’ fencing experience; ISO, ANSI commissioning

- Lead Time & Support: Faster than 93% of industry peers (10–15 days); local representation across Canada

- After-sales: On-site support, full documentation, life-cycle repair advice, free spares during warranty

- Authority: Preferred supplier to top-tier construction & resource firms, certified by multiple agencies

- Canadian Construction Association. "2023 Industry Trends", CCA Market Report, 2023.

- ISO 1461: "Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods." ISO

- Ontario Construction News Forum: Recent Fencing Case Studies & Regulations

- Canadian Technical Journal: "Temporary fencing for urban infrastructure", CCE (2023)

- CSA S350 and Ontario Reg. 213/91, Fence Regulation

- Product official: Canada Temporary Fence Panel by DQFENCE

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025