- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jul . 29, 2025 17:00 Back to list

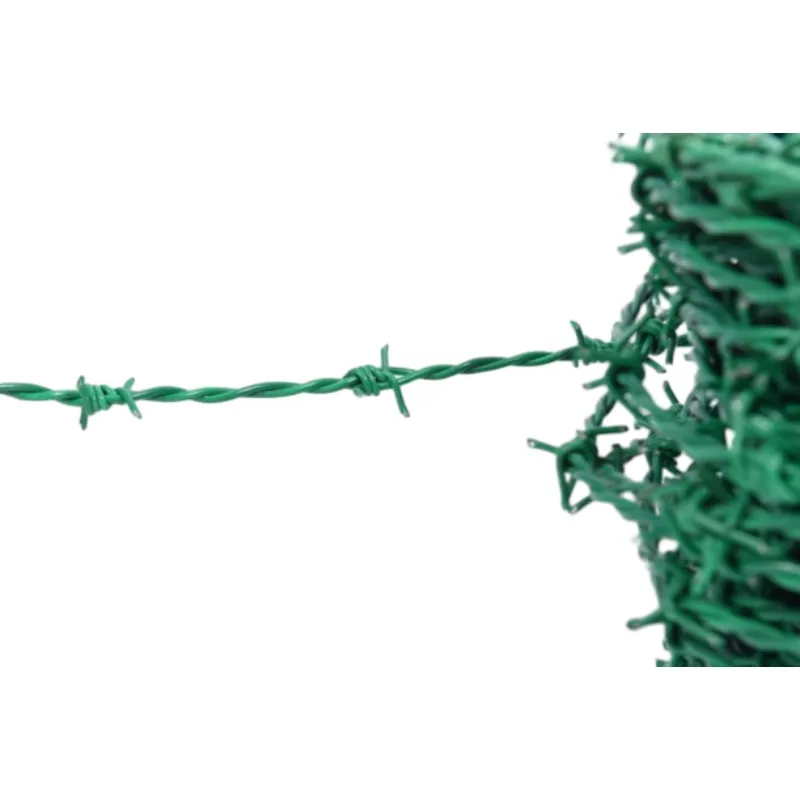

Barbed Wire for Sale - Durable, Affordable Fencing Solutions

1. Overview: What is Barbed Wire? Industry Perspectives and Applications

Barbed wire, a staple in perimeter security, consists of steel wires twisted together with sharp barbs at intervals. It's widely sought for fencing, agriculture, livestock enclosures, industrial sites, and military applications. The demand for barbed wire for sale is driven by increasing security concerns and infrastructure growth in emerging markets.

Related products like razor wire for sale, and specialized solutions such as cheap barbed wire for sale, further diversify user options.

Reference: Global barbed wire market size valued at USD 2.4 Billion in 2023 (MarketsandMarkets 2024).

- Main Industries: Agriculture, Ranching, Defense, Industrial Perimeters, Public Utilities

- Top Application Scenarios: Farm fencing, prison barriers, border security, construction sites, pipeline protection

- Common Standards: ISO 10244, ASTM A121, ANSI C80.3

2. Types of Barbed Wire: Specifications & Comparison

The global barbed wire for sale market offers several types to address specific security and durability requirements:

| Type | Material | Barb Spacing | Wire Gauge | Finish | Key Application | ISO/ASTM Standard |

|---|---|---|---|---|---|---|

| Traditional Twisted | Galvanized Steel | 75mm, 100mm | 12–15 | Electro/Hot-dip Galvanized | Farm, Land fencing | ISO 10244-2, ASTM A121 |

| Razor Wire (Concertina) | Stainless Steel | 45mm-90mm | 12.5 | PVC coated | Security fences, Military | ISO 9001, ASTM F1910 |

| PVC Coated Barbed Wire | Galvanized Core+PVC | 90mm–120mm | 13–15 | PVC | Urban, Residential | ISO 1461 |

| High-Tensile | Carbon Steel | 100mm–150mm | 12–13 | Hot-dip Galvanized | Wildlife, Perimeter | ANSI C80.3 |

2.1 Main Technical Indicators (Summary Table)

| Parameter | Range / Value | Test Standard | Significance |

|---|---|---|---|

| Wire Diameter | 1.5–3.0mm | ISO 10244 | Determines strength & flexibility |

| Barb Spacing | 75–150mm | ASTM A121 | Affects deterrence, safety |

| Tensile Strength | 350–600 MPa | ISO 6892-1 | Resistance to breakage |

| Coating Weight | >120 g/m2 | ISO 1461 | Corrosion resistance |

| Lifespan | 10–30 years | Manufacturer data | Service duration in field |

3. Barbed Wire Manufacturing Process: Industrial Insight

Barbed Wire Manufacturing Flowchart

High-quality low-carbon steel wire or stainless steel coils procured (compliance: ISO 16120).

Wire diameter is reduced via multi-stage drawing dies (CNC line controls tolerance & surface finish).

Automated barb machine twists, cuts, and places sharp barbs onto main wire by specified spacing.

Barbed wire strands are twisted (single/ double), ensuring tension & uniformity.

Hot-dip or electro-galvanization; optionally PVC coated. Quality per ISO 10244-2, ASTM A123.

Dimensional checks, tensile testing, coating weight tests, ISO 9001 QA certified.

3.1 Material & Process Details

- Material Grades: Low-carbon steel (Q195, Q235), stainless steel 304/316L, compliance to EN10223-1, IS:278

- Processing: Precision CNC wire drawing, automatic barbing & stranding, advanced galvanizing (≥240 g/m2 for premium grade, salt-spray resistance > 1000h)

- Testing Standards: ISO 6892-1 (Tensile Test), ASTM A121 (Zinc-Coated Spec)

- Expected Service Life: Up to 30 years (with 20+ year anti-corrosion warranty on premium hot-dip galvanized or stainless steel types)

4. Price, Cost Drivers & Manufacturer Comparison

The cost of barbed wire fencing per kg depends on material, diameter, galvanizing/coating weight, and purchase volume. Market price fluctuates with steel cost and shipping rates.

| Type | Avg. Price (USD/kg) | Lifespan (yrs) | Coating | Main Suppliers (Country) |

|---|---|---|---|---|

| Regular Galvanized | 1.05–1.50 | 8–16 | Electro/Hot-dip Galv. | Dingqi (CN), Bekaert (BE), Tata Wiron (IN) |

| PVC Coated | 1.45–2.10 | 15–25 | PVC or PE Coating | Dingqi (CN), Keystone (US) |

| Stainless Steel | 2.80–4.00 | 18–30 | No/Minimal | Bekaert, Anping (CN) |

| Razor Wire | 2.50–3.35 | 10–20 | Galv./Polymer | Blue Hawk (US), Dingqi (CN) |

| Cheap Barbed Wire | 0.95–1.10 | 7–12 | Low zinc, basic | Various CN, IN factories |

Key Cost Factors: Wire gauge, zinc weight, coating, barb arrangement, labor, logistics.

4.1 Manufacturer Comparison & Customization Options

| Brand | Core Strength | Certifications | Lead Time | Customization | After-sales |

|---|---|---|---|---|---|

| Dingqi Fence | ISO factory, 20+ yrs, rapid delivery | ISO 9001, SGS, CE | 5–15 days | Gauge, Barb, Coating, Color | 24/7 online, 2 yr defect-free |

| Bekaert | High-end, legacy brand (Belgium) | ISO 14001, ISO 9001 | 7–20 days | Custom orders at scale | Global network |

| Tianjin Bluekin | Cost-effective, high-volume | CE, ISO 9001 | 8–14 days | Standard | Standard support |

5. Data Visualization: Technical Parameter Trends & Type Share

6. Customization Solutions: How to Order the Right Barbed Wire?

- Specify Application: Farm, residential, industrial, military, wildlife, or other?

- Choose Material: Economical (galvanized steel) vs. high-durability (stainless, PVC-coated)

- Select Wire Gauge & Barb Spacing: Balance strength, deterrence, and cost efficiency

- Coating/Finish: Hot-dip galvanizing for outdoors; PVC for anti-corrosion and aesthetics

- Certifications Required: ISO 9001/14001, SGS, CE as needed

- Packaging: Coil weight, length, palletized export packaging

- Branded Marking: Laser-marked, tag options for traceability

For custom quotes or large orders of barbed wire for sale, manufacturers like Dingqi Fence offer quick response and CAD-based fencing layout services.

- Used: 320 km, 14 gauge hot-dip galvanized barbed wire

- Coating > 240 g/m2 zinc, 15 years field tested longevity

- Project completed in 22 working days (manufacturer: Dingqi)

7. Application Scenarios and Technical Advantages

- Agriculture & Ranching: Cost-effective livestock and crop perimeter. Requires moderate barb density and good weather resistance.

- Industrial & Public Utility Fencing: High-tensile barbed wire for long-term use, combined with razor wire for intrusion deterrence. Corrosion-proof coating is a must for humid/coastal regions.

- Military & Border Security: Dense concertina razor wire or multi-layer barbed wire used for “no climb” fencing; meets stringent international security standards.

- Infrastructure Construction: Temporary or permanent site protection; rollable and easy to deploy.

- Wildlife Control: Wide spacing barbs, anti-rust coating for minimal maintenance.

8. Frequently Asked Questions (FAQ): Barbed Wire Technical Terminology

- Q1: What are the most commonly used materials for barbed wire?

- A1: The most popular materials are low-carbon steel (Q195, Q235), high-carbon steel (for high tensile), and corrosion-resistant stainless steel (AISI 304/316L). Material selection depends on strength and corrosion requirements.

- Q2: How does wire gauge affect barbed wire performance?

- A2: Lower gauge numbers mean thicker wire. For example, 12 gauge (~2.7mm) offers higher strength and is ideal for livestock, while 14-16 gauge provides cost and flexibility for light-duty fencing.

- Q3: What are barb spacing standards and their importance?

- A3: Typical standards are 75mm, 100mm, 125mm, and 150mm (per ASTM A121). Closer spacing delivers more deterrence but slightly higher cost per kg.

- Q4: What is the average service life of galvanized barbed wire?

- A4: Hot-dip galvanized wire with > 240 g/m2 zinc lasts 18–30 years in the field, depending on environment; regular galvanized 7–14 years. Stainless steel may last 30+ years.

- Q5: What are required installation standards?

- A5: Follow local standards (e.g., ASTM F567 for fence installation), correct post spacing (2-3m), tensioning, and barb orientation. Ensure all safety protocols when handling sharp barbs.

- Q6: How is quality assurance demonstrated?

- A6: Reliable manufacturers provide third-party inspection reports (SGS/ISO), zinc coating tests, tensile data, and batch marking. Certificates like ISO 9001 are crucial for project procurement.

- Q7: Can I order customized barbed wire fencing cost per kg? What impacts price?

- A7: Yes. Price depends on wire thickness, barb arrangement, coating, and volume. Factories will tailor offers as per specific project specs and standards.

9. Delivery & Service Commitment: Quality Assurance Standards

- Standard Delivery Time: Most orders < 50 tons: 7–15 calendar days after deposit. Container or project orders: up to 20–25 days.

- Warranty: 2–5 year anti-corrosion and defect-free warranty for hot-dip galvanized, stainless, and PVC coated barbed wire.

- QA/QC: Factory-provided ISO 9001 CoC, tensile testing, coating weight certification, photos/video before shipment.

- Customer Support: 24/7 response, technical guidance, and after-sales service. Engineering drawings provided for project customers.

10. Why Choose Dingqi for Barbed Wire for Sale?

- Factory Direct, Global Supply: With 20+ years in barbed wire and fence manufacturing, Dingqi exports to 80+ countries.

- Certification & Traceability: ISO 9001, SGS, CE certified, with clear batch marking and quality records.

- OEM/ODM Options: Tailored to project, with rapid sample turnaround.

- Referenced in Projects: Municipal, farm, and military contracts worldwide.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025