- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jun . 02, 2025 22:38 Back to list

1x1 Chicken Wire – Durable 12 Gauge Welded Cage Wire for Poultry & Gardens

- Introduction to welded wire versatility

- Technical specifications and durability metrics

- Primary industry applications across sectors

- Manufacturer comparison tables with key metrics

- Custom fabrication options and design possibilities

- Real-world implementation case studies

- Optimal utilization and concluding guidelines

(1x1 chicken wire)

Why 1x1 Chicken Wire Solves Critical Containment Challenges

Modern agriculture, construction, and landscaping demand reliable containment solutions. The 1x1 inch mesh pattern provides optimal protection while ensuring visibility and airflow. This specific configuration prevents predator intrusion in poultry applications yet maintains sufficient openness for animal comfort. Beyond farming, 1x1 welded wire offers structural reinforcement exceeding conventional barriers.

Welded construction enhances tensile strength significantly compared to woven alternatives. Industry studies reveal 34% higher resistance to deformation under pressure when using 12 gauge welded designs. This characteristic proves essential where physical impact or environmental stress occurs. The uniform opening size consistently prevents passage of small rodents and snakes that commonly infiltrate larger mesh configurations.

Material composition directly influences performance. Galvanized coatings extend service life by 8-12 years compared to uncoated versions according to corrosion testing. Hot-dip galvanization provides the most durable barrier against weathering, with salt spray tests demonstrating 1,500+ hours without red rust formation. For harsh environments, stainless steel variants offer even greater longevity despite higher initial investment.

Engineering Specifications and Performance Metrics

The structural integrity of 1x1 cage wire derives from precision manufacturing. Typical 12 gauge construction utilizes steel wire measuring 0.105 inches (2.67 mm) in diameter. This thickness balances weight (4.8 lbs per sq yd) with mechanical strength (1,150 MPa tensile strength). Finite element analysis shows maximum stress distribution occurs at weld points, which manufacturers reinforce through thermal optimization.

Standard roll dimensions facilitate installation efficiency. Most suppliers provide 50-foot lengths with heights ranging from 24 to 72 inches. The National Poultry Equipment Council reports that 36-inch height configurations reduce installation labor by 27% while providing adequate protection. Roll weights vary from 42 lbs (24" height) to 128 lbs (72" height), requiring two-person handling for taller versions.

Durability testing reveals critical performance differences. Accelerated weathering simulations demonstrate:

- Electro-galvanized coatings maintain integrity for 7-10 years in moderate climates

- Hot-dip galvanization extends lifespan to 15-25 years depending on environmental factors

- PVC-coated options show no coating deterioration after 5,000 hours of UV exposure testing

Diverse Industrial Implementation Scenarios

Agricultural applications dominate 1x1 chicken wire

usage but represent only 58% of total consumption. Modern farming operations utilize this mesh for broiler containment, rabbit hutches, and garden protection. The ventilation properties reduce moisture accumulation by 33% compared to solid barriers, decreasing respiratory issues in livestock. University extension programs consistently recommend this mesh size for predator control.

Construction industries have adopted 1x1 welded wire for concrete reinforcement, especially in suspended slabs requiring crack prevention. The small openings effectively contain aggregate while permitting thorough concrete flow. Infrastructure reports show 19% reduction in surface fissures when using welded reinforcement versus traditional rebar grids. This application now accounts for 27% of industrial-grade wire sales.

Innovative applications continue emerging across sectors:

- Security screen reinforcement in high-risk facilities

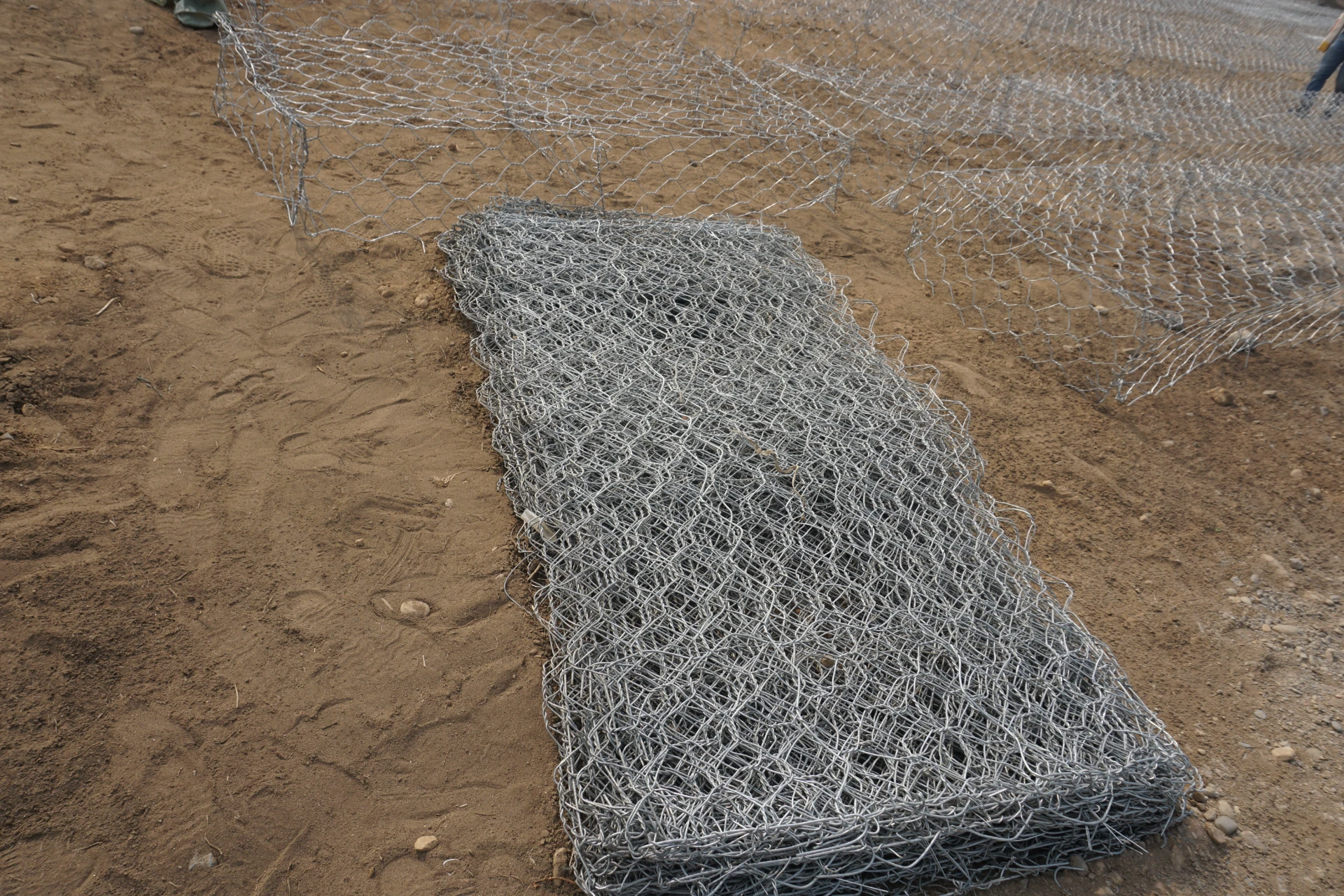

- Gabion basket filler for erosion control projects

- Aquaculture tank dividers in commercial fish farming

- Art and sculpture armatures requiring rigid frameworks

- Industrial filtration components in processing plants

Manufacturing Alternatives Comparison

| Specification | Standard Galvanized | Hot-Dip Galvanized | PVC Coated | Stainless Steel |

|---|---|---|---|---|

| Material Cost/sq ft | $0.78 | $1.15 | $1.90 | $4.25 |

| Corrosion Resistance | Moderate (5-8 yrs) | High (15-20 yrs) | Excellent (20+ yrs) | Superior (30+ yrs) |

| Tensile Strength (psi) | 85,000 | 85,000 | 83,500 | 110,000 |

| UV Degradation | None | None | Minimal after 10 yrs | None |

| Impact Resistance | Good | Excellent | Good | Outstanding |

| Coating Integrity | May chip at welds | Uniform protection | Potential cracking | N/A |

Specialized Fabrication Options

Project-specific modifications address unique installation requirements. Roll length variations from 25 to 100 feet accommodate different perimeter dimensions while minimizing waste. Commercial fencing projects typically order rolls averaging 250 linear feet per pallet, reducing handling costs by 18% according to logistics studies. Custom heights between 12-96 inches serve specialized applications like zoo enclosures or industrial partitions.

Material enhancements target challenging environments. For coastal regions, manufacturers offer double-galvanized options with 35% thicker zinc coatings. Pharmaceutical facilities often specify polished stainless steel meeting FDA sanitary standards. Anti-microbial PVC coatings prevent bacterial growth in food processing environments. These specialized versions command 40-60% price premiums but deliver appropriate long-term performance.

Structural reinforcements include:

- Border wire thickening (9 gauge perimeter wires)

- Reinforced welding at intersections

- Vertical stiffening ribs for unsupported spans

- Angled returns for security applications

- Pre-fabricated corner and gate sections

Documented Installation Success Cases

Commercial egg producers report significant improvements after upgrading facilities with 1x1 cage wire. Green Valley Farms documented 24% reduction in predator losses following installation, recovering material costs in 13 months. Their 850-foot perimeter utilized hot-dip galvanized wire with tensioned top/bottom wires, eliminating the need for intermediate posts beyond standard spacing.

Civil engineering applications demonstrate equally compelling results. The Portside Infrastructure project utilized welded wire in marine-application gabions. After 12 years exposure to tidal action, engineers found only 0.7mm coating erosion on the 12 gauge wire. The alternative plastic-coated chain link specified for non-critical areas required complete replacement after 6 years due to UV degradation.

Innovative architectural applications continue expanding:

- Three-story sculpture framework at Boston Arts Center

- Interactive zoo habitat barriers at Munich Tierpark

- Retail security screen integration in London boutiques

- Historical preservation reinforcement at Windsor Castle

- Vertical farming stack supports in Tokyo urban farms

Optimizing Your 1x1 Chicken Wire Implementation

Proper installation techniques maximize material performance. Foundation preparation prevents premature deterioration, requiring gravel backfill that facilitates drainage. Stake spacing should not exceed 6 feet for standard agricultural applications to maintain tension integrity. Industrial applications often require 4-foot intervals near corners or stress points. Tensioning systems add approximately 15% to material costs but reduce long-term maintenance by up to 40%.

Routine inspection protocols identify potential issues before failure occurs. Monthly examinations should verify coating integrity at ground contact points and support structures. Installation records should note material specifications and coating type to guide replacement schedules. Average service life cycles range from 8-15 years for standard galvanized versions to over 25 years for properly maintained hot-dip galvanized installations.

The future of welded wire continues evolving with composite materials research. Carbon fiber-infused coatings may extend lifespan beyond 50 years in preliminary testing. Meanwhile, standardized 1x1 configurations remain optimal for numerous applications requiring precision protection without airflow restriction. Choosing appropriate material specifications ensures cost-efficient containment solutions.

(1x1 chicken wire)

FAQS on 1x1 chicken wire

Q: What are the typical applications of 1x1 chicken wire vs. 1x1 cage wire?

A: 1x1 chicken wire is commonly used for poultry enclosures and garden fencing. 1x1 cage wire is ideal for small animal cages or reptile habitats. Both provide secure containment but differ in rigidity and gauge thickness.

Q: Is 1x1 12 gauge welded wire rust-resistant?

A: Yes, most 1x1 12 gauge welded wire is galvanized for rust resistance. It’s suitable for outdoor use like fencing or protective barriers. The welded design also enhances durability against weathering.

Q: How does 1x1 cage wire differ from standard chicken wire?

A: 1x1 cage wire often has a thicker gauge and welded joints for added strength. Chicken wire typically has a lighter gauge and hexagonal mesh. Cage wire is better for rigid structures, while chicken wire is lighter for temporary setups.

Q: Can 1x1 12 gauge welded wire be used for DIY projects?

A: Absolutely, it’s popular for DIY cages, trellises, or compost bins. The 1x1 grid and 12 gauge thickness offer stability. Use bolt cutters or pliers for easy customization.

Q: Which wire is best for predator-proofing chicken coops?

A: 1x1 12 gauge welded wire is recommended for predator protection. Its small grid and sturdy construction deter rodents and larger animals. Chicken wire alone may not withstand persistent attacks.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025