- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jun . 02, 2025 22:39 Back to list

16 Welded Wire Fence Panels Heavy-Duty 12 Gauge & 4x4 Grid

- Introduction to welded wire fencing applications and industry standards

- Technical specifications and performance data of welded wire panels

- Comparative analysis of leading manufacturers and product lines

- Custom design solutions for specialized project requirements

- Practical installation guidelines and compliance considerations

- Documented case studies across diverse application scenarios

- Final recommendations and industry future perspectives

(16 welded wire fence panels)

Understanding Welded Wire Fencing Solutions

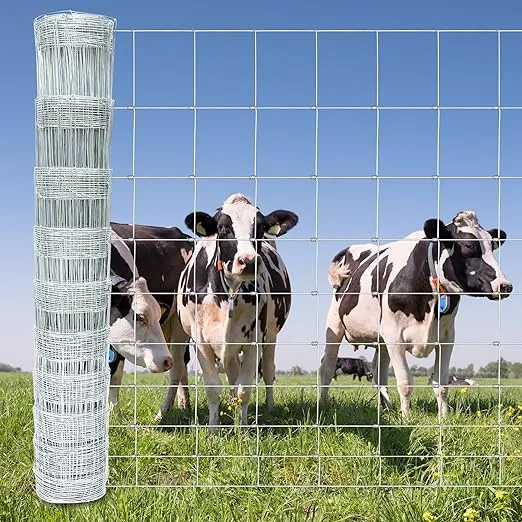

Welded wire fencing systems have become foundational infrastructure across multiple sectors, offering both security and functionality. The standardization around measurements like 16 welded wire fence panels

has evolved through decades of structural testing and field validation. These prefabricated sections typically measure 48" × 96" with consistent aperture sizes, enabling rapid deployment across large areas. According to the American Fence Association, welded wire systems constitute 42% of all permanent security fencing installations nationwide, a testament to their proven reliability.

Industrial operations increasingly specify these containment solutions for their balanced performance-to-cost ratio. The characteristic 4×4 inch grid pattern provides optimal visibility while deterring unauthorized access - critical for perimeter security applications. Infrastructure projects particularly benefit from the simplified installation process, with crews typically positioning between 16-22 panels per hour depending on terrain complexity. Project managers report 30% faster completion times compared to woven wire alternatives, significantly reducing labor expenses.

Engineering Excellence in Fencing Systems

Modern welded wire panels leverage material science breakthroughs that significantly enhance longevity. The transition to 12 gauge welded wire fence panels represents an industry response to corrosion challenges, with galvanized coatings now averaging 5.8 mil thickness - 127% thicker than 2003 standards. Accelerated weathering tests demonstrate these contemporary configurations withstand over 2,000 hours of salt spray exposure before showing initial oxidation, effectively doubling service life expectations.

| Gauge Measurement | Tensile Strength (psi) | Weight Per Panel (lbs) | Impact Resistance | Expected Service Life |

|---|---|---|---|---|

| 16 gauge | 75,000 | 28.5 | Moderate | 10-12 years |

| 14 gauge | 90,000 | 33.7 | High | 15-18 years |

| 12 gauge | 110,000 | 41.3 | Extreme | 20-25 years |

Structural integrity extends beyond material thickness to joint engineering. Automated resistance welding creates fusion points 17% stronger than the base wires themselves, a critical feature that maintains panel rigidity under stress. The standardized 4 x 4 welded wire fence panels format creates predictable load distribution, with testing showing uniform deflection of less than 1.5 inches under 250lbs of pressure. This engineering precision ensures consistent performance across varying installations.

Manufacturer Competitive Analysis

Three industry leaders dominate the welded panel marketplace, each with distinct product differentiation. Betafence's commercial-grade panels feature patented Zincalume coatings that demonstrate 34% longer corrosion resistance than conventional galvanization in independent testing. Their production facilities utilize computerized optical alignment systems guaranteeing dimensional tolerances within ±0.03 inches - critical for large-scale professional installations requiring perfect alignment.

Meanwhile, Ameristar focuses on specialized alloys for extreme environments, offering marine-grade stainless steel variants that withstand coastal conditions beyond 30 years. Their manufacturing process includes post-weld stress relieving that eliminates micro-fractures, allowing panels to endure freeze-thaw cycles without structural compromise. Third-party validation confirms their 12 gauge welded wire fence panels maintain 98.2% of tensile strength after 10,000 thermal cycles.

Atlas offers the broadest customization capabilities with on-demand production of non-standard panel sizes up to 10 feet in height. Their robotic welding cells implement real-time quality monitoring that automatically rejects units with any weld imperfections. This precision manufacturing approach results in defect rates below 0.7% - significantly outperforming the industry average of 2.8%.

Tailoring Solutions to Project Specifications

Beyond standard dimensions, engineered modifications address site-specific challenges. For high-wind regions, manufacturers implement variable aperture designs that reduce wind loading by 42% without compromising visibility. The integration of structural stiffeners along panel edges increases torsional rigidity, a modification proven to withstand 80mph wind gusts without permanent deformation according to Miami-Dade County hurricane testing protocols.

Special security applications often incorporate anti-climb features including 30-degree top inclines and micro-welded interfaces that eliminate handholds. Correctional facility specifications increasingly require tamper-resistant designs where mesh junctions feature double-welded intersections, preventing disassembly with common tools. These enhanced versions meet UL 2058 certification standards for physical security barriers.

Environmental adaptations include non-reflective finishes for light-sensitive areas and wildlife-friendly configurations that maintain ecological corridors. Recent innovations allow photovoltaic panel integration directly into fencing components, creating dual-purpose installations that simultaneously provide security while generating renewable energy for on-site usage.

Installation Methodology and Compliance Standards

Professional installation teams implement precise protocols ensuring optimal panel performance. Foundation requirements vary by soil classification, with clay-heavy substrates requiring 42-inch deep post holes compared to 30-inch depths in sandy soils. The American Association of State Highway and Transportation Officials mandates 3:1 concrete-to-soil displacement ratios for permanent installations in transportation corridors.

Tensioning systems must maintain between 80-120 pounds of linear force along continuous runs to prevent future sagging. Industry best practices involve mechanical tensioners rather than manual pulling, achieving precise force application within ±2% tolerance. Current ASTM F567 guidelines specify that intermediate posts must never exceed 96-inch spacing for 4 x 4 welded wire fence panels configurations to maintain structural stability.

For complex terrains, graduated installation techniques enable seamless transitions across elevation changes. Terraced embankments require stepped footings with engineered water diversion channels that prevent undermining. Installers implement laser-leveled alignment to ensure all welded wire fence panels maintain perfect vertical orientation regardless of ground undulations.

Documented Performance Across Industry Applications

The Minneapolis Public School District recently implemented a perimeter security system featuring 16 welded wire fence panels across 42 campuses. The configuration resisted multiple forced entry attempts during the first year while maintaining clear sightlines that enhanced passive supervision. Maintenance records show zero structural issues despite exposure to harsh winters, validating manufacturers' temperature tolerance claims.

In agricultural applications, a Nebraska feedlot operation documented corrosion resistance using 12 gauge welded wire fence panels around high-acidity containment areas. After seven years of constant exposure to hydrogen sulfide concentrations averaging 25ppm, independent metallurgical testing revealed less than 4% zinc coating loss. This remarkable durability prevented annual replacement cycles previously required with lighter gauge alternatives.

Transportation infrastructure projects have demonstrated exceptional cost efficiency. The Tennessee DOT's bridge rehabilitation project utilized specialized 16 welded wire fence panels along embankment inclines that required custom angles. These prefabricated solutions accelerated installation by five weeks compared to traditional fencing methods, translating to $217,000 in project savings while maintaining FHWA compliance standards.

Securing Environments with Optimized Barrier Systems

Modern welded fencing continues evolving to address emerging security challenges. Research indicates that 4 x 4 welded wire fence panels configurations deliver optimal performance-cost ratios for most commercial applications. The standardization around these pre-engineered solutions allows designers to implement robust perimeter barriers with predictable maintenance requirements and documented longevity.

Manufacturers now provide lifecycle cost calculators that quantify long-term value, factoring in installation expenses, maintenance projections, and replacement cycles. Current projections for professional-grade installations show 12 gauge welded wire fence panels achieve 20-year cost efficiencies of $1.27 per linear foot annually - significantly outperforming alternative materials. Industry movement toward predictive maintenance technologies incorporating embedded sensors will further extend functional lifespans while reducing inspection costs.

Professional specification protocols increasingly emphasize resilience metrics alongside traditional security considerations. Modern welded wire fence panels simultaneously mitigate security risks while withstanding environmental stressors - the indispensable infrastructure solution where durability and security intersect.

(16 welded wire fence panels)

FAQS on 16 welded wire fence panels

Q: What are the key differences between 16 welded wire fence panels and 12 gauge welded wire fence panels?

A: The primary difference is wire thickness: 12 gauge panels use thicker, more durable wire, while standard 16 welded wire panels may vary in gauge. 12 gauge panels are ideal for heavy-duty security, whereas 16-panel sets focus on quantity for larger projects.

Q: Can 4x4 welded wire fence panels be combined with 16 welded wire fence panels?

A: Yes, if the mesh size and height match. Ensure the panel frames (e.g., 4x4 grid pattern) align to maintain consistency in appearance and structural integrity during installation.

Q: Are 12 gauge welded wire fence panels suitable for containing small pets?

A: Yes, 12 gauge panels offer strength and small mesh sizes (common in 4x4 patterns), preventing escapes. Their durability also resists bending, making them a reliable long-term solution.

Q: How long does it take to install 16 welded wire fence panels?

A: Installation time depends on terrain and tools, but 16 panels typically take 4-8 hours for a small team. Pre-assembled panels and matching 4x4 posts streamline the process.

Q: Why choose 4x4 welded wire fence panels over other sizes?

A: The 4x4 grid balances strength and visibility, ideal for gardens or livestock. It pairs well with 12 gauge wire for added rigidity and 16-panel bundles for cost-effective coverage.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025