- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

ส.ค. . 27, 2025 04:40 Back to list

Premium Barbed Wire for Sale - Secure & Affordable Fencing

Advanced Solutions for Perimeter Security: Understanding Barbed Wire Technology

In an era where robust perimeter security is non-negotiable across diverse industrial sectors, the demand for reliable deterrents remains paramount. Our comprehensive guide delves into the specifics of barbed wire for sale, offering an in-depth analysis for B2B decision-makers, procurement specialists, and engineering teams. This article explores the manufacturing intricacies, technical specifications, diverse applications, and inherent advantages of modern barbed wire solutions, essential for safeguarding critical infrastructure and assets.

From agricultural applications to high-security installations, understanding the nuances of different types of barbed wire and their suitability for specific environmental and threat profiles is crucial. We provide data-driven insights, highlight industry standards, and compare various vendor offerings to assist in making informed purchasing decisions for superior security infrastructure.

The Manufacturing Process of High-Tensile Barbed Wire

The production of high-quality barbed wire for sale is a meticulously controlled industrial process, ensuring durability, deterrent efficacy, and longevity. Unlike traditional manufacturing with extensive casting or forging, barbed wire production primarily involves wire drawing, surface treatment, and precise mechanical twisting. Our products adhere strictly to international standards like ISO 9001 for quality management and ASTM A121 for zinc-coated (galvanized) steel barbed wire.

Detailed Process Flow:

- Wire Rod Procurement: We begin with high-carbon or low-carbon steel wire rods, selected for specific tensile strength and ductility requirements. Material certifications are rigorously checked to ensure compliance with international steel standards.

- Wire Drawing: The steel rods undergo a multi-stage cold drawing process to reduce their diameter to the desired gauge (e.g., 12.5 gauge or 15.5 gauge). This process significantly increases the wire's tensile strength and uniformity, critical for preventing easy cutting or bending.

- Surface Treatment (Galvanization/PVC Coating):

- Hot-Dip Galvanization: The drawn wires are immersed in molten zinc, creating a metallurgically bonded, thick coating of zinc. This provides exceptional corrosion resistance, extending the service life significantly, especially in harsh environments. The zinc coating weight typically ranges from 45 g/m² to 275 g/m², conforming to standards like ASTM A641.

- Electro-Galvanization: A thinner, aesthetically uniform zinc coating is applied electrolytically. While providing good initial protection, its corrosion resistance is generally less than hot-dip galvanized variants, making it suitable for less aggressive environments or for subsequent PVC coating.

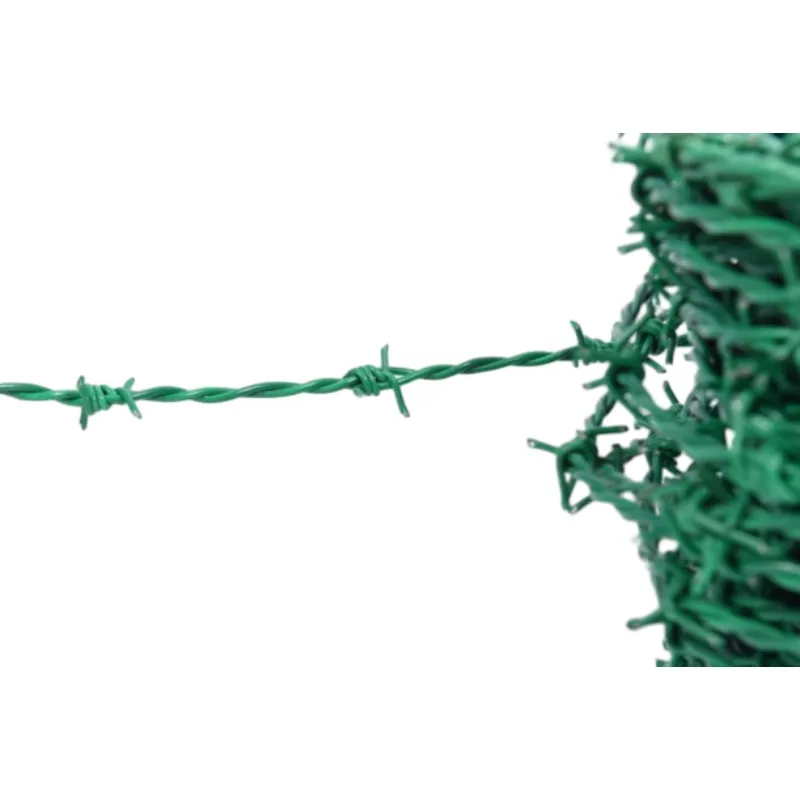

- PVC Coating: For enhanced corrosion resistance and visual integration, galvanized wire can be further coated with a durable layer of PVC. This option is popular in residential, commercial, and coastal applications, offering aesthetic appeal alongside superior protection.

- Barbing and Twisting: Two main line wires (strand wires) are fed into specialized machinery. Shorter barb wires are then twisted around one or both line wires at precise intervals (e.g., 4-point barbs every 4 or 5 inches). The machine then interlocks the line wires to secure the barbs firmly in place. This mechanism ensures that the barbs remain rigid and effective as a deterrent.

- Coiling and Packaging: The finished barbed wire is coiled into standard roll lengths (e.g., 200m or 400m) and securely packaged for transport. Packaging often includes a plastic wrap or hessian cloth to protect the galvanization during transit and storage.

Our manufacturing facilities incorporate advanced CNC machining for precision tooling and automated processes to maintain consistent quality and output efficiency. Every batch undergoes stringent quality control testing, including tensile strength tests (per ASTM A370), zinc coating adherence tests, and barb spacing verification, ensuring each roll of barbed wire for sale meets or exceeds industry benchmarks.

Industry Trends and Market Dynamics for Security Fencing

The market for perimeter security solutions, including barbed wire for sale and razor wire for sale, is experiencing steady growth driven by increasing security threats, infrastructure development, and regulatory mandates. Key trends include:

- Enhanced Durability and Longevity: A growing preference for heavily galvanized or PVC-coated barbed wire to minimize maintenance and replacement costs, especially in corrosive environments (e.g., coastal regions, industrial complexes).

- Integrated Security Solutions: Barbed wire is increasingly used in conjunction with other security measures such as CCTV, access control, and electronic intrusion detection systems, forming multi-layered defense perimeters.

- Demand for Specialized Configurations: Customization in terms of wire gauge, barb spacing, and coating types to meet specific project requirements, particularly for high-security installations or specific agricultural needs.

- Focus on Sustainable Production: Manufacturers are exploring more eco-friendly galvanization processes and materials, aligning with global sustainability initiatives.

The global barbed wire market is projected to reach approximately USD 1.5 billion by 2027, with a CAGR of over 4% from 2022 to 2027, propelled by rising security concerns in critical infrastructure, defense, and border control. This growth underscores the enduring relevance and continued innovation in the production of deterrent fencing.

Technical Specifications and Product Parameters

Understanding the precise technical specifications is crucial when selecting barbed wire for sale. Parameters such as wire gauge, barb configuration, material, and surface treatment directly influence performance, service life, and cost-effectiveness. Our products are engineered for maximum deterrence and longevity.

Standard Barbed Wire Specifications:

| Parameter | Description/Value Range |

|---|---|

| Material | High Tensile Steel (HTS) or Mild Steel (MS) |

| Wire Gauge (Line Wire) | 12.5 gauge (2.5mm), 14 gauge (2.0mm), 15.5 gauge (1.8mm) |

| Wire Gauge (Barb Wire) | 14 gauge (2.0mm), 16 gauge (1.6mm) |

| Number of Strands | 2-strand (Double Strand) |

| Number of Barbs | 4-point (Standard), 2-point (Less common for security) |

| Barb Spacing | 3 inches (7.5 cm), 4 inches (10 cm), 5 inches (12.5 cm), 6 inches (15 cm) |

| Surface Treatment | Hot-Dip Galvanized, Electro-Galvanized, PVC Coated |

| Zinc Coating Weight | 45-275 g/m² (ASTM A121/A641 compliant) |

| Tensile Strength | 350-550 N/mm² (for HTS), 250-350 N/mm² (for MS) |

| Roll Lengths | 200m, 250m, 400m, or customized |

| Service Life | 10-25 years depending on coating and environment |

Our products typically feature the "IOWA" type barb, known for its robust construction and effective deterrent capabilities. For specialized high-security applications, clients often opt for lower gauge (thicker) wires and shorter barb spacing to maximize intrusion resistance.

Application Scenarios and Target Industries

The versatility of barbed wire for sale makes it indispensable across numerous sectors requiring robust perimeter control and deterrence. Its cost-effectiveness and formidable physical barrier properties are key factors in its widespread adoption.

Primary Target Industries:

- Agriculture and Ranching: Used extensively for livestock containment, crop protection, and demarcation of property boundaries. High-tensile, galvanized wire is favored for its long service life against environmental exposure.

- Petrochemical and Energy Sector: Critical for securing refineries, power plants, substations, and pipelines. Here, corrosion resistance (heavy galvanization or PVC coating) is paramount due to exposure to chemicals and harsh outdoor conditions.

- Military and Defense: Essential for border security, military bases, temporary checkpoints, and conflict zones, often deployed in conjunction with razor wire for sale for maximum deterrence.

- Metallurgy and Mining: Securing expensive equipment, processing facilities, and storage areas from unauthorized access.

- Water Supply & Drainage Infrastructure: Protecting water treatment plants, pumping stations, reservoirs, and dams from vandalism and sabotage.

- Commercial and Industrial Facilities: Securing warehouses, factories, construction sites, and equipment yards, often as an economic deterrent topping on chain-link or welded mesh fences.

- Correctional Facilities: While often supplemented by razor wire, barbed wire remains a foundational layer of security in perimeter defense for prisons and detention centers.

In all these scenarios, the selection of the correct gauge, barb type, and coating is critical. For instance, in high-security environments, combining barbed wire with robust fencing provides a layered defense, significantly increasing the time and effort required for unauthorized entry, thereby enhancing overall security posture.

Technical Advantages and Performance Metrics

Our barbed wire for sale is engineered to deliver superior technical advantages, ensuring optimal performance and long-term reliability in demanding environments:

- Exceptional Corrosion Resistance: Our hot-dip galvanized barbed wire boasts a zinc coating of up to 275 g/m², providing a protective layer that can withstand harsh weather conditions, salinity, and industrial pollutants for up to 25 years without significant degradation. This dramatically reduces the need for frequent replacement, offering substantial long-term savings.

- High Tensile Strength: Utilizing high-tensile steel wire (typically 350-550 N/mm²), our barbed wire exhibits superior resistance to cutting, stretching, and impact. This makes it an effective physical deterrent against both human intruders and large animals, maintaining structural integrity even under stress.

- Effective Anti-Climb Deterrence: The sharp, strategically placed barbs act as a significant psychological and physical deterrent, making unauthorized scaling of fences extremely difficult and risky. This inherent property is key to preventing breaches in secure perimeters.

- Cost-Effectiveness: Compared to more complex electronic security systems, barbed wire offers a highly effective, low-maintenance, and cheap barbed wire for sale solution for perimeter security. Its installation cost per linear meter is significantly lower, making it an economically viable option for extensive boundaries.

- Versatile Integration: It can be easily integrated with various fencing types, including chain-link, welded mesh, and solid walls, enhancing existing security infrastructure without extensive modifications.

Our commitment to quality ensures that each roll contributes to a robust and energy-saving security solution, by reducing the dependency on continuous human patrolling in non-critical areas, thereby optimizing operational costs.

Vendor Comparison and Competitive Edge

When evaluating vendors for barbed wire for sale, several factors distinguish top-tier suppliers. Our company, with over two decades of specialized experience in fence manufacturing, stands out through:

- Certifications and Compliance: We hold ISO 9001 certification for quality management and ensure all products comply with relevant ASTM and ANSI standards for materials and galvanization. Our internal testing protocols exceed minimum industry requirements.

- Material Traceability: Full traceability of raw materials from reputable steel mills, ensuring consistent quality and performance.

- Manufacturing Consistency: State-of-the-art automated production lines minimize human error and ensure uniform product quality across large orders.

- Customization Capabilities: Ability to provide specialized solutions for unique project demands (e.g., specific wire gauges, barb spacing, coating thicknesses, or PVC colors).

- Logistics and Global Reach: Efficient global shipping and logistics support, ensuring timely delivery to diverse international clients.

Comparative Analysis of Barbed Wire Types (Cost vs. Performance):

| Type of Barbed Wire | Initial Cost (Relative) | Corrosion Resistance | Service Life | Ideal Application |

|---|---|---|---|---|

| Electro-Galvanized (Light) | Lowest | Fair (10-20 g/m² zinc) | 3-5 years | Temporary fencing, dry inland areas |

| Hot-Dip Galvanized (Standard) | Medium | Good (45-80 g/m² zinc) | 10-15 years | General agriculture, commercial use |

| Hot-Dip Galvanized (Heavy Duty) | High | Excellent (150-275 g/m² zinc) | 20-25+ years | Industrial, coastal, high-security |

| PVC Coated (over Galv.) | Highest | Superior (Dual protection) | 15-20 years | Aesthetic, highly corrosive zones, residential |

Customized Solutions and Application Case Studies

We understand that off-the-shelf solutions may not always meet the precise demands of every B2B project. Therefore, we offer extensive customized solutions for barbed wire for sale, tailoring products to specific environmental challenges, security threat levels, and budget considerations.

Customization Options Include:

- Wire Gauge and Tensile Strength: Tailoring wire diameters to achieve specific break strengths for enhanced resistance to cutting.

- Barb Configuration and Spacing: Adjusting barb length, number of points, and interval to maximize deterrence for particular security risks.

- Advanced Coatings: Offering specialized PVC colors for aesthetic integration or heavy-duty zinc-aluminum alloy coatings for extreme corrosion resistance.

- Roll Dimensions: Custom roll lengths and weights to facilitate easier installation in specific project layouts or to comply with transport regulations.

Application Case Studies:

Case Study 1: Perimeter Security for a National Energy Grid Substation

Challenge: A critical energy substation in a humid, coastal environment required a high-security, low-maintenance perimeter to deter vandalism and unauthorized entry. The existing fencing suffered rapid corrosion, leading to frequent replacements.

Solution: We supplied 50km of our heavy-duty, hot-dip galvanized (275 g/m² zinc coating), 12.5 gauge barbed wire for sale with 4-point barbs every 3 inches. This was installed atop a robust chain-link fence system.

Outcome: After 5 years, the barbed wire showed no signs of corrosion, significantly reducing maintenance costs and enhancing overall site security. The enhanced deterrence capability was praised by the client's security team.

Case Study 2: Wildlife Exclusion for a Large-Scale Agricultural Project

Challenge: A multi-thousand-acre agricultural project faced significant crop damage from local wildlife. The solution needed to be cost-effective for extensive coverage while ensuring humane deterrence.

Solution: We provided large rolls (400m) of standard hot-dip galvanized 14-gauge barbed wire with 4-point barbs at 5-inch spacing, integrated into a multi-strand electric fence system. This choice balanced the need for effective deterrence with an economical price point for extensive use.

Outcome: Crop damage was reduced by over 80% within the first season, demonstrating the effectiveness of appropriately selected barbed wire fencing cost per kg solutions for large-scale agricultural protection. The client appreciated the balance of performance and budget.

Trustworthiness and Customer Support

Building lasting relationships with our B2B clients is founded on transparency, reliability, and unparalleled customer support. We are committed to ensuring complete satisfaction with every order of barbed wire for sale.

Frequently Asked Questions (FAQ):

- Q1: What is the typical lead time for a large order?

- A1: Standard orders typically have a lead time of 2-4 weeks, depending on volume and customization. For urgent or exceptionally large projects, please contact our sales team for expedited production schedules.

- Q2: What are your warranty commitments?

- A2: We offer a 1-year warranty against manufacturing defects on all our barbed wire products. Our galvanized products carry an extended performance guarantee specific to their coating weight and environmental application, ensuring long-term material integrity against corrosion.

- Q3: Can you provide installation guidance or recommendations?

- A3: While we do not directly offer installation services, our technical support team can provide comprehensive guidance on best practices for installation, appropriate tools, and safety considerations. We can also recommend trusted installation partners in various regions.

- Q4: How does your pricing for cheap barbed wire for sale compare with industry averages?

- A4: Our pricing strategy focuses on providing competitive rates without compromising on quality or compliance with international standards. We offer various grades to meet different budget requirements, from cost-effective electro-galvanized options for temporary use to premium heavy-duty galvanized wire for critical, long-term applications. For detailed barbed wire fencing cost per kg or per roll, please request a custom quote.

After-Sales Support:

Our dedicated customer support team is available from Monday to Friday, 9:00 AM to 5:00 PM (GMT+8), to assist with any technical queries, order tracking, or after-sales service requirements. We prioritize rapid response times and efficient problem resolution to minimize any potential project delays or disruptions.

For inquiries regarding our premium barbed wire for sale solutions, please visit our website or contact our sales department directly. We are committed to providing the highest quality products and professional service to meet your security needs.

References

- ASTM A121/A121M-13, Standard Specification for Zinc-Coated (Galvanized) Steel Barbed Wire. ASTM International, West Conshohocken, PA, 2013.

- ASTM A641/A641M-09, Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. ASTM International, West Conshohocken, PA, 2009.

- ISO 9001:2015, Quality management systems – Requirements. International Organization for Standardization, Geneva, Switzerland, 2015.

- Market Research Future. (2022). Barbed Wire Market Research Report - Forecast to 2027.

-

Wholesale T Posts: Bulk Metal & Steel T Posts for Sale

NewsAug.28,2025

-

Comprehensive Guide to Wire Mesh Solutions: Security, Durability, and Customization

NewsAug.24,2025

-

Comprehensive Guide to Welded Fencing Solutions: Durability, Security, and Style

NewsAug.24,2025

-

Comprehensive Guide to Livestock Fence Panels: Safety and Efficiency for Your Animals

NewsAug.24,2025

-

Comprehensive Guide to Temporary Fencing Solutions: From Construction Sites to Events

NewsAug.24,2025

-

Hebei Dunqiang Hardware Mesh Co., Ltd. – Your Reliable Partner in Wire Mesh Solutions

NewsAug.24,2025