- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Gus . 18, 2025 17:30 Back to list

Why Welded Gabions Are Redefining Modern Landscape

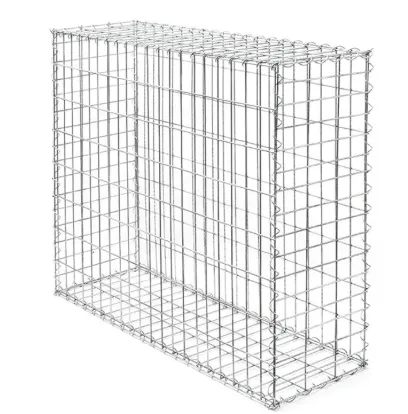

In today’s construction and landscape industries, welded gabion structures are transforming how we think about durability and design. Unlike traditional woven gabions, a welded gabion is crafted from precision-welded steel wire mesh panels, forming a rigid and clean-edged container that can be filled with stones, rocks, or other materials. This makes them not only functionally superior but also visually refined.

Welded gabion cages are increasingly favored in applications where structural integrity, uniformity, and aesthetics are essential. From modern garden retaining walls and public seating units to erosion control barriers and highway sound walls, these gabions offer unparalleled versatility.

One of the key advantages of a welded gabion lies in its dimensional stability. The uniform square or rectangular mesh openings maintain their shape under pressure, making these cages perfect for load-bearing walls or decorative facades. Moreover, they’re faster and easier to assemble compared to their woven counterparts, which adds to labor cost savings and time efficiency.

Working with a Trusted Welded Gabion Manufacturer: Quality Matters

Choosing a reputable welded gabion manufacturer is critical to ensure long-term strength, anti-corrosion performance, and ease of installation. A high-quality welded gabion manufacturer uses low-carbon steel wire or galvanized wire, with optional coatings like PVC or Galfan to increase corrosion resistance, particularly in marine or acidic environments.

An established welded gabion manufacturer offers customizable mesh sizes, wire diameters (commonly from 3.0 to 5.0mm), and dimensions to fit various engineering or architectural needs. Whether it’s a 1m x 1m x 2m retaining wall or a thinner decorative garden unit, manufacturers can fabricate solutions tailored to specific load requirements and installation environments.

Beyond the product itself, a reliable welded gabion manufacturer provides technical support, layout advice, and detailed assembly instructions—critical for contractors, designers, and end-users alike. The consistency and accuracy of their welding technology ensure structural integrity, even under extreme compression or shifting loads.

By partnering with the right welded gabion manufacturer, you gain more than a product—you gain a trusted engineering component that integrates beautifully into modern landscapes, infrastructure, and architecture.

What Is the Purpose of a Gabion? More Than Just a Rock Cage

What is the purpose of a gabion? While many associate gabions with civil engineering applications, the answer goes far beyond erosion control. At its core, a gabion is a flexible, permeable, and environmentally friendly structural system. Filled with rock, concrete debris, or decorative stones, gabions provide excellent drainage, pressure relief, and landscape integration.

Their natural material fill allows gabions to blend seamlessly into surrounding environments, while their modular structure enables custom configurations in virtually any setting. In short, the purpose of a gabion is both practical and artistic—a perfect union of strength and style.

Benefits of Welded Gabions in Civil and Architectural Projects

Whether used in heavy infrastructure or creative landscaping, welded gabion cages offer a range of benefits unmatched by traditional materials. Their strength, modularity, and permeability make them ideal for addressing site challenges with elegance.

One of the standout features of a welded gabion is its exceptional durability. The welded structure resists deformation under lateral loads, ensuring long-term performance even in demanding applications like bridge abutments or cliff-side stabilizations. When filled with angular stone, the gabion provides excellent friction and resistance to water flow, making it ideal for flood zones or river engineering.

The visual appeal of welded gabion installations also adds value to real estate projects. Gabion walls can be integrated with greenery, lighting, or architectural features to create stunning outdoor environments that are both sustainable and eye-catching.

Furthermore, gabions allow water to pass freely through the structure, reducing hydrostatic pressure and minimizing the risk of wall failure in saturated soils. This self-draining capability not only protects infrastructure but also supports groundwater recharge and erosion control.

Innovating with Welded Gabion Manufacturer Partnerships for Custom Solutions

Collaboration with a knowledgeable welded gabion manufacturer opens doors to bespoke solutions that combine technical engineering with design flexibility. From high-retaining infrastructure walls to artistic garden installations, manufacturers are increasingly working hand-in-hand with landscape architects, civil engineers, and developers.

Custom gabion solutions may include pre-assembled panels, unique coatings, variable mesh configurations, and rapid deployment cages for disaster relief. In urban settings, designers now use welded gabion cages to support vertical gardens, integrate seating into landscape plans, or enclose HVAC units with natural cladding.

A top-tier welded gabion manufacturer will often provide not just products but also logistics planning, assembly training, and structural load testing support. For governments, developers, or design-build firms, these services are critical in meeting project deadlines and regulatory compliance.

With modern laser welding and automated production lines, the consistency and scale of welded gabion manufacturing have reached new heights. This ensures that every cage fits with precision, installs quickly, and maintains long-term performance in even the harshest environments.

welded gabion FAQs

What is the difference between welded gabions and woven gabions?

Welded gabions are made from rigid steel wire panels that are welded at each intersection, resulting in a more stable and clean-lined structure. Woven gabions, by contrast, use twisted wire mesh and are more flexible. Welded gabions are better for architectural applications and easier to install, while woven gabions are preferred for uneven terrains due to their flexibility.

How long do welded gabions last?

A high-quality welded gabion with galvanized or Galfan-coated wire can last over 50 years in dry environments and up to 25–35 years in coastal or acidic areas. Longevity depends on coating quality, exposure to water or pollutants, and correct installation. Regular inspections and quality fill material can help extend their life.

Can I use a welded gabion in residential landscaping?

Absolutely! Welded gabions are increasingly used in residential projects for retaining walls, raised garden beds, decorative benches, fire pits, and privacy screens. Their clean structure, custom sizes, and stone-fill versatility make them perfect for modern landscape aesthetics.

What is the purpose of a gabion in flood-prone areas?

In flood-prone zones, the purpose of a gabion is to control erosion, absorb hydraulic energy, and stabilize banks or slopes. Their permeable structure allows water to flow through while keeping soil and rock in place. Gabions help reduce water speed and prevent damage to infrastructure during high-flow events.

How do I choose a reliable welded gabion manufacturer?

Look for a welded gabion manufacturer that offers certifications (ISO, ASTM), high-quality galvanized or PVC/Galfan coatings, customizable sizing, and technical support. A reliable manufacturer will provide detailed product specifications, load testing data, and installation guidance. It’s also helpful to ask for project case studies or references.