- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Dec . 04, 2024 15:57 Back to list

Wire Mesh Manufacturing Solutions for Diverse Industrial Applications and Custom Fabrication

Understanding Wire Mesh Fabricators An Essential Component in Modern Manufacturing

Wire mesh fabricators play a critical role in various industries, providing specialized services that deliver customized wire mesh products. These fabricators produce an array of wire mesh types, which are utilized in construction, agriculture, food processing, and many other sectors. This article explores the significance of wire mesh fabricators, their processes, and the diverse applications of wire mesh products.

What is Wire Mesh?

Wire mesh is a grid-like structure created by weaving or welding wires together. The openings can vary in size and shape, making wire mesh versatile for different applications. The materials used can range from stainless steel to copper, depending on the specific requirements of the project.

The Role of Wire Mesh Fabricators

Wire mesh fabricators are responsible for the design and manufacture of wire mesh products tailored to meet specific customer needs. Their expertise allows them to create custom solutions, including standard mesh sheets, specialized fabrics, and complex structures used in various applications.

The fabrication process typically involves several key steps

1. Design Consultation Fabricators work closely with clients to understand their specific needs, including size, material, and application. This initial consultation ensures that the final product will meet all requirements.

2. Material Selection The choice of wire material is crucial. Fabricators can offer a range of options, including galvanized steel, stainless steel, and plastic-coated wire, each with its own unique properties suitable for different environments.

3. Manufacturing Depending on the design specifications, wire mesh can be produced through methods such as welding or weaving. Automated machinery is often employed to ensure precision and efficiency in the production process.

wire mesh fabricators

4. Finishing Once the mesh is fabricated, it may undergo further processing, including coating for corrosion resistance or treatments to enhance durability.

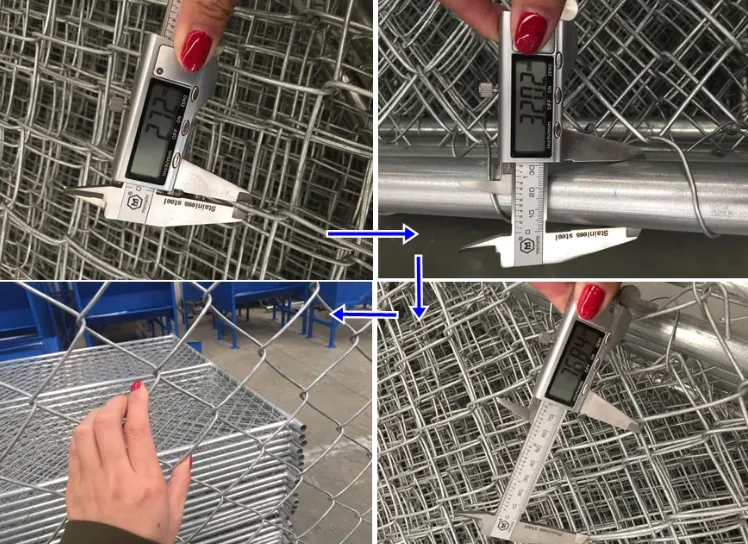

5. Quality Control Rigorous testing and inspections are performed at various stages of production to ensure that the wire mesh meets industry standards and customer expectations.

Applications of Wire Mesh

Wire mesh finds utility across numerous industries. In construction, it is often used for reinforcement in concrete, providing strength and stability to structures. In agriculture, wire mesh fencing is an essential tool for protecting crops from animals and pests.

The food processing industry relies on wire mesh for various purposes, including conveying, filtering, and separating materials. For example, wire mesh screens are essential for sifting flour or separating different grades of grains. Additionally, wire mesh is widely used in designing safes, grates, and partitions, making it a crucial material in many manufacturing processes.

In environmental applications, wire mesh serves as an effective barrier for erosion control, water filtration, and even habitat restoration. Its ability to permit drainage while providing structural support makes it a preferred material for engineers and ecologists alike.

Staying Updated with Innovation

As industries evolve, wire mesh fabricators continue to innovate, experimenting with new materials and manufacturing techniques. Advances in technology, such as 3D printing and automated welding, are paving the way for custom wire mesh solutions that are not only stronger but also more cost-effective.

In conclusion, wire mesh fabricators are vital players in the manufacturing landscape. By producing a diverse range of wire mesh products tailored to meet specific client needs, they contribute significantly to the efficiency and effectiveness of multiple industries. As demand increases for more specialized wire mesh applications, the role of fabricators will only become more paramount in driving innovation and ensuring quality in manufactured solutions. Whether for construction, agriculture, or any other sector, wire mesh provides the foundational support necessary for success.

-

The Vital Role of Wire Mesh in Construction

NewsJul.01,2025

-

The Essential Benefits of Welded Wire Mesh

NewsJul.01,2025

-

Secure Your Property with Field Farm Fence

NewsJul.01,2025

-

Expert Chain Link Fence Installation

NewsJul.01,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsJul.01,2025

-

Barbed Wire

NewsJul.01,2025