- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Dec . 14, 2024 20:05 Back to list

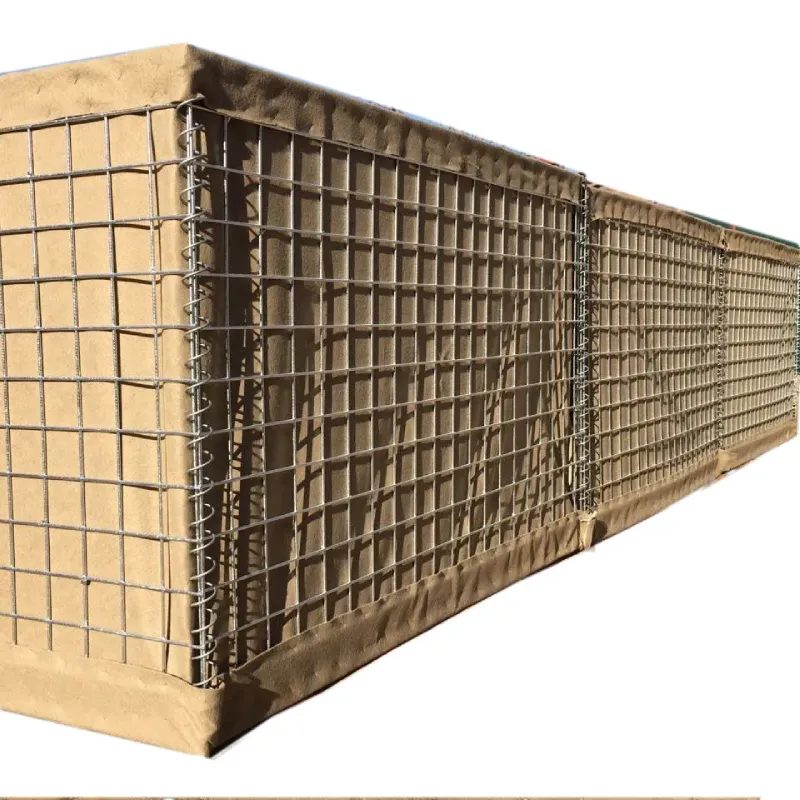

Understanding BRC Wire Mesh and Its Applications in Construction and Fencing

Understanding BRC Wire Mesh A Key Component in Construction

BRC wire mesh, also known as welded wire mesh, is a versatile material widely used in the construction industry. This mesh is made from high-quality steel wires that are welded together at regular intervals to form a grid pattern. The term BRC stands for the British Reinforcement Company, which played a pivotal role in the mesh’s popularization. Due to its strength, durability, and cost-effectiveness, BRC wire mesh has become a preferred choice for various applications in construction and civil engineering.

Composition and Manufacturing Process

BRC wire mesh is typically manufactured from mild steel wires, which can be treated with anti-corrosive coatings to enhance longevity. The manufacturing process involves drawing the steel into wires of specific diameters and then welding them at intersections to create a rigid mesh. The spacing between the wires can vary, allowing for customization based on specific engineering requirements.

Applications of BRC Wire Mesh

BRC wire mesh is incredibly versatile and finds application in numerous sectors, including

1. Reinforcement of Concrete One of the most common uses of BRC wire mesh is to reinforce concrete structures. When embedded within concrete slabs, it enhances tensile strength, preventing cracking and ensuring structural integrity.

2. Flooring BRC wire mesh is often used in the construction of industrial and residential flooring. It provides additional support to concrete floors and helps maintain level surfaces, which is crucial for durability and aesthetics.

3. Walls and Fencing The mesh is also utilized for building walls and fencing in construction projects. Its strength makes it an effective barrier against intrusion while also providing essential support for plastering or rendering.

4. Agricultural Applications In agriculture, BRC wire mesh is commonly employed in making fencing for livestock and crops. It provides a sturdy deterrent against animal intrusion while allowing air and light to pass through.

what is brc wire mesh

5. Custom Fabrications Beyond traditional uses, BRC wire mesh can also be fabricated into custom designs for specialized projects. This adaptability makes it an essential material for architects and engineers looking to achieve specific design outcomes.

Benefits of Using BRC Wire Mesh

1. Strength and Durability BRC wire mesh provides exceptional strength due to its welded construction, making it suitable for heavy-duty applications.

2. Cost-Effectiveness Compared to traditional reinforcement methods, using BRC wire mesh can be more economical. Its ease of installation reduces labor costs, contributing to overall savings in construction budgets.

3. Quick Installation Pre-manufactured BRC wire mesh is readily available in various sizes and configurations, allowing for quick and efficient installation on site. This benefit helps accelerate project timelines.

4. Reduces Cracking Concrete structures reinforced with BRC wire mesh exhibit reduced cracking over time, extending the lifespan of the construction project and minimizing maintenance needs.

5. Versatility With various wire diameters and mesh sizes, BRC wire mesh can be tailored to meet specific construction requirements, making it an indispensable material in modern engineering.

Conclusion

BRC wire mesh serves as a foundational element in contemporary construction, providing strength, stability, and adaptability to various structures. As architects and engineers continuously seek innovative materials to enhance building performance, BRC wire mesh stands out as a reliable and cost-effective solution. Its diverse range of applications and benefits solidify its role as a crucial component in the construction toolkit, ultimately contributing to safer and more durable infrastructure. Whether for residential, industrial, or agricultural applications, the role of BRC wire mesh in enhancing structural integrity cannot be understated.

-

The Vital Role of Wire Mesh in Construction

NewsJul.01,2025

-

The Essential Benefits of Welded Wire Mesh

NewsJul.01,2025

-

Secure Your Property with Field Farm Fence

NewsJul.01,2025

-

Expert Chain Link Fence Installation

NewsJul.01,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsJul.01,2025

-

Barbed Wire

NewsJul.01,2025