- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Dec . 29, 2024 06:02 Back to list

Different Varieties of BRC Wire Mesh for Various Applications and Uses

Understanding the Different Types of BRC Wire Mesh

BRC wire mesh, commonly known as welded wire mesh or reinforcement mesh, is an essential component in construction and civil engineering. It consists of a series of wire strands that are welded together at intersecting points, forming a grid-like structure. This type of mesh is primarily used to reinforce concrete, offering strength and stability to various structures. In this article, we will explore the different types of BRC wire mesh, their applications, and the benefits they provide.

Types of BRC Wire Mesh

1. Standard Welded Wire Mesh

The standard welded wire mesh comprises wires that are uniformly spaced and welded at regular intervals. This type is primarily used for general reinforcement in concrete slabs, floors, and walls. The wire's diameter and spacing can vary based on specific project requirements. The standard mesh offers excellent tensile strength, making it a popular choice among builders.

2. Heavy-Duty Welded Wire Mesh

As the name suggests, heavy-duty welded wire mesh is designed to withstand heavier loads. With thicker wire diameters and closer spacing, this type of mesh is commonly used in applications where additional strength is necessary, such as in bridge decks, industrial flooring, and heavy machinery bases. It provides enhanced durability and resistance to cracking, particularly in high-stress areas.

3. Galvanized Wire Mesh

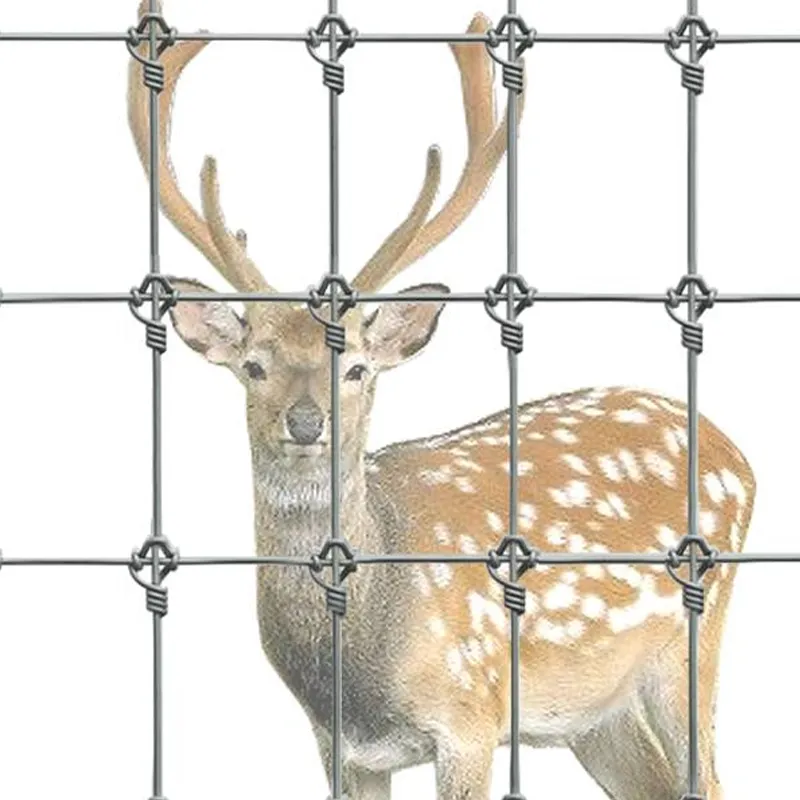

Galvanized BRC wire mesh is coated with zinc to prevent corrosion and increase longevity. This type is particularly suitable for outdoor applications, where exposure to moisture and other environmental factors can lead to rust and degradation. Galvanized mesh is often used in paving, landscaping, and fencing, offering a longer lifespan while maintaining structural integrity.

4. Polymer Coated Wire Mesh

Another corrosion-resistant option, polymer-coated wire mesh is coated with a layer of plastic or polymer, providing a barrier against moisture and chemicals. This type is often used in applications involving exposure to harsh chemicals or extreme weather conditions. Its aesthetic appeal also makes it suitable for decorative structures, such as garden fences and railings.

5

. Seismic Wire Meshtypes of brc wire mesh

In regions prone to seismic activity, specialized seismic wire mesh is designed to enhance the earthquake resistance of structures. This type of mesh typically features a unique pattern of wire placement to accommodate the dynamic loads during an earthquake. Its strength and flexibility help to distribute forces more evenly across the concrete, reducing the risk of cracking and structural failure.

6. Custom BRC Wire Mesh

For specialized projects that do not fit conventional standards, custom BRC wire mesh can be manufactured to meet specific requirements. Builders can specify the wire diameter, mesh size, and configuration, allowing for tailored solutions that best fit the structural demands of a project. Custom mesh is often used in unique architectural designs or complex construction scenarios.

Applications of BRC Wire Mesh

The versatility of BRC wire mesh makes it suitable for various applications, including

- Flooring Used in residential, commercial, and industrial floors for added strength and crack resistance. - Walls Reinforcement of concrete walls in buildings, waterways, and retaining structures. - Pavements Used in roads, parking lots, and driveways to enhance load-bearing capabilities. - Fencing Some types of BRC wire mesh serve as effective barriers for security and property delineation. - Landscaping In garden beds and plant supports, providing structure and protection for vegetation.

Benefits of Using BRC Wire Mesh

Implementing BRC wire mesh in construction offers numerous benefits

- Increased Strength Provides significant tensile strength to concrete structures, reducing the risk of fractures and structural failures. - Cost-Effectiveness Reduces the amount of concrete needed by effectively distributing loads, potentially lowering material costs. - Easy Installation Typically lightweight and easy to handle, speeding up the construction process. - Durability With options for corrosion-resistant coatings, BRC wire mesh can withstand harsh conditions, prolonging the life of structures.

Conclusion

In summary, BRC wire mesh comes in various types, each tailored to meet the specific reinforcement needs of construction projects. From standard welded mesh to specialized seismic variants, understanding these types allows builders and engineers to select the right mesh for their unique applications. By incorporating BRC wire mesh into construction designs, enhanced strength, durability, and overall structural integrity can be achieved, contributing to safer and more reliable buildings and infrastructures.

-

The Vital Role of Wire Mesh in Construction

NewsJul.01,2025

-

The Essential Benefits of Welded Wire Mesh

NewsJul.01,2025

-

Secure Your Property with Field Farm Fence

NewsJul.01,2025

-

Expert Chain Link Fence Installation

NewsJul.01,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsJul.01,2025

-

Barbed Wire

NewsJul.01,2025