- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Aug . 07, 2025 05:00 Back to list

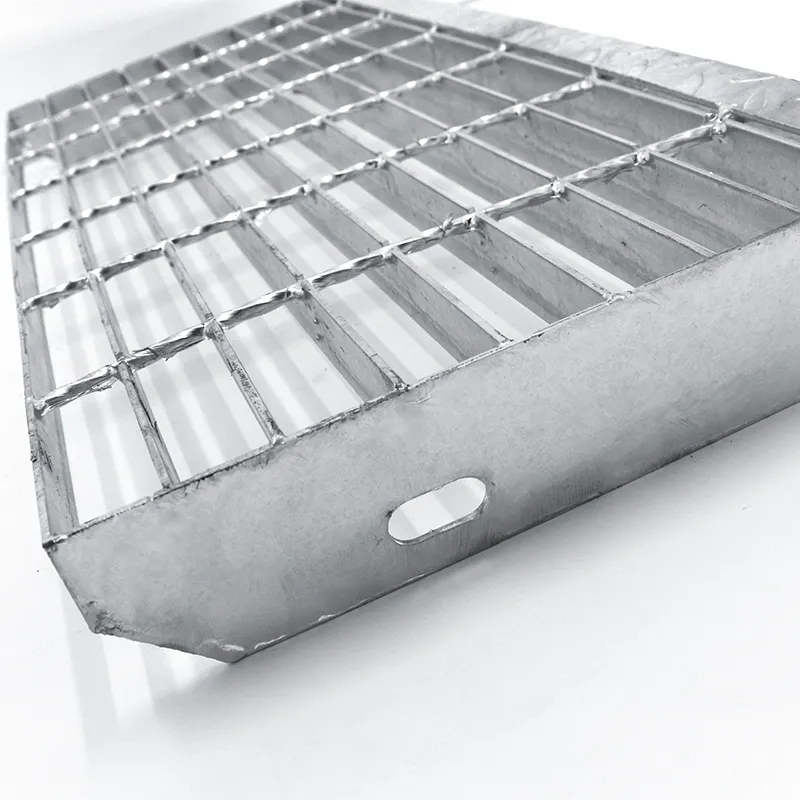

Steel Grating For Sale: Durable Metal Bar Grating Solutions

In the vast landscape of industrial infrastructure, few components offer the versatility, strength, and durability of steel grating. As industries globally seek robust, cost-effective, and safe solutions for flooring, walkways, platforms, and drainage, the demand for high-quality steel grating for sale continues to surge. This comprehensive guide delves deep into the world of industrial grating, focusing on the critical aspects of product understanding, technical specifications, manufacturing excellence, diverse applications, and the vital elements that build trust and authority for buyers seeking the best solutions.

Industry Trends and Market Dynamics in **Metal Grating for Sale**

The global market for industrial gratings, particularly steel grating for sale, is experiencing robust growth driven by several key trends. Rapid urbanization, increasing investments in infrastructure development, and the expansion of industrial sectors like oil & gas, petrochemicals, power generation, and manufacturing are primary catalysts. According to a recent market analysis by Grand View Research, the global industrial flooring market size, which includes grating, was valued at USD 5.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030. This growth underscores the essential role of durable and reliable flooring solutions.

Technological advancements in manufacturing processes, such as advanced welding techniques and surface treatments like hot-dip galvanization, are enhancing the lifespan and performance of grating products, making them more appealing for long-term investments. Furthermore, there's a growing emphasis on safety standards and ergonomic designs in industrial environments, pushing manufacturers to innovate anti-slip surfaces and lighter-weight yet strong grating solutions. The increasing adoption of Building Information Modeling (BIM) in construction and industrial projects also facilitates more precise planning and integration of components like steel grating, optimizing material usage and reducing waste.

Understanding **Steel Grating** and its Core Components

Steel grating, often referred to as metal grating or bar grating, is a heavy-duty product primarily used for industrial and commercial flooring applications where strength, ventilation, and light penetration are critical. It typically consists of a series of bearing bars and cross bars, permanently joined together to form a load-bearing panel. The method of joining defines the type of grating:

- Welded Steel Grating: The most common type, where bearing bars are resistance-welded to the cross bars, creating a strong and rigid panel. This process ensures high strength and durability.

- Press-Locked Steel Grating: Bearing bars are notched, and cross bars are pressed into the notches, locking them into place without welding. This provides a clean aesthetic and is suitable for architectural applications or lighter loads.

- Swaged Steel Grating: Bearing bars are slotted, and round or square cross bars are inserted and swaged (cold-formed) under hydraulic pressure. This method offers excellent strength and rigidity.

The primary materials used include carbon steel (most common, often galvanized), stainless steel (for corrosive environments), and sometimes aluminum (for lightweight applications). Our focus here is primarily on the robust and versatile steel grating for sale made from carbon steel, known for its exceptional strength-to-cost ratio.

Technical Parameters and Product Specifications of **Bar Grating**

When considering steel grating for sale, understanding its technical parameters is crucial for selecting the right product for your application. Key specifications include:

- Bearing Bar Size: Defined by its depth and thickness (e.g., 25x3mm). Deeper and thicker bars yield greater load-bearing capacity.

- Bearing Bar Spacing: The center-to-center distance between adjacent bearing bars (e.g., 30mm, 40mm). Wider spacing allows for more light and air passage but reduces load capacity.

- Cross Bar Spacing: The center-to-center distance between cross bars (e.g., 50mm, 100mm). Affects lateral rigidity and the size of objects that can fall through.

- Mesh Size: The combination of bearing bar and cross bar spacing, dictating the open area (e.g., 30x100mm, 40x50mm).

- Surface Treatment: Most commonly hot-dip galvanized after fabrication for superior corrosion resistance. Other options include painting or self-color (untreated).

- Load-Bearing Capacity: The maximum weight the grating can safely support, calculated based on material, bar size, and spacing, following industry standards like ANSI/NAAMM MBG 531-09.

Table 1: General Parameters for Steel Grating

| Parameter | Common Range/Description | Impact on Performance |

|---|---|---|

| Material Grades | ASTM A36, ASTM A1011, Q235, S235JR (mild steel) | Determines fundamental strength, weldability, and cost. |

| Bearing Bar Size (Depth x Thickness) | 25x3mm to 100x10mm (common) | Directly impacts load capacity and span capability. Deeper/thicker = stronger. |

| Bearing Bar Spacing | 30mm, 40mm, 50mm, 60mm (common) | Affects open area, light/air penetration, and load distribution. Smaller spacing for heavier loads. |

| Cross Bar Spacing | 50mm, 100mm (common) | Enhances lateral stability; affects size of objects that can fall through. |

| Surface Type | Plain, Serrated (anti-slip) | Serrated provides enhanced slip resistance, crucial for wet or oily environments. |

| Surface Treatment | Hot-Dip Galvanized, Painted, Self-Color | Hot-dip galvanization (HDG) offers superior corrosion protection and lifespan, typically to ASTM A123. |

| Standard Panel Sizes | 1000x5800mm, 995x6000mm (common manufacturing sizes) | Optimized for material efficiency and handling during fabrication/installation. |

| Typical Usage | Walkways, platforms, drainage covers, stair treads, sun shades | Versatile application across industrial, commercial, and architectural sectors. |

Table 2: DQ Fence Steel Bar Grate Key Specifications

Our flagship product, the Steel Bar Grate, is engineered for maximum performance and longevity, meeting stringent international standards.

| Parameter | DQ Fence Specification | Technical Advantage |

|---|---|---|

| Product Name | Steel Bar Grate | |

| Material | High-Quality Q235B Carbon Steel or Equivalent (e.g., ASTM A36) | Excellent strength-to-weight ratio, ensuring robust load-bearing capacity. |

| Manufacturing Process | Electro-forged Welding (High-pressure resistance welding) | Ensures a permanent fusion of bearing and cross bars, providing exceptional strength and rigidity, preventing loosening. |

| Standard Bearing Bar Sizes | 25x3mm, 32x5mm, 40x5mm, 50x5mm (custom available) | Versatile options for various load requirements and span capabilities. |

| Standard Bearing Bar Spacing | 30mm, 40mm (e.g., G303/30, G405/30) | Optimized for industrial walkways, platforms, and drainage, balancing safety and light penetration. |

| Standard Cross Bar Spacing | 50mm, 100mm | Provides excellent lateral stability and prevents large debris from falling through. |

| Surface Finish | Hot-Dip Galvanized per ASTM A123/A123M | Superior corrosion protection, significantly extending product lifespan even in harsh environments. Average zinc coating thickness of 610g/m² for bars over 5mm thick. |

| Safety Feature | Optional Serrated Surface | Enhanced anti-slip properties, crucial for high-traffic or wet industrial areas. |

| Design Standard Compliance | ANSI/NAAMM MBG 531-09, AS1657, BS4592, YB/T4001.1-2007 (China) | Guarantees product quality, safety, and performance meet recognized international benchmarks. |

| Lifespan Expectancy | 20+ years (with proper maintenance in typical environments) | Long-term durability ensures low total cost of ownership. |

**Steel Grating** Manufacturing Process Explained

The creation of high-quality steel grating is a meticulous process that combines advanced machinery with precise engineering. Our manufacturing process ensures that every panel of steel grating for sale meets the highest standards of strength, durability, and safety. Here's a detailed breakdown:

Material Preparation & Cutting

The process begins with sourcing high-grade steel (Q235B or ASTM A36). Bearing bars and cross bars are precisely cut to required lengths and dimensions using automated cutting machines, ensuring accuracy and minimal material waste. This initial step is critical for the structural integrity of the final product.

Electro-Forged Welding (The Core Process)

This is the cornerstone of our high-quality bar grating production. Bearing bars are arranged vertically at specific intervals. Cross bars are then fused to the bearing bars under immense pressure and high electrical current. This electro-forged resistance welding process creates a permanent, solid joint without the need for additional filler material, ensuring incredible strength and rigidity. The result is a monolithic panel that can withstand significant loads and impacts. (Imagine a short video illustrating this high-pressure welding process, showing sparks and fusion)

Edge Banding (Optional but Recommended)

For added strength, stability, and a finished appearance, the ends of the grating panels are often banded with a steel flat bar. This edge banding is typically welded to the ends of the bearing bars, preventing twisting and improving load distribution, especially when panels are subject to heavy traffic or dynamic loads.

Inspection & Quality Control

Before surface treatment, each grating panel undergoes rigorous inspection. This includes dimensional checks (length, width, mesh size), visual inspection for welding integrity, and flatness. This stage ensures adherence to design specifications and internal quality standards (e.g., meeting ISO 9001:2015 criteria for manufacturing excellence). Any imperfections are addressed before proceeding.

Surface Treatment: Hot-Dip Galvanization

To provide unparalleled corrosion resistance and extend lifespan, our steel grating for sale undergoes hot-dip galvanization. This process involves:

- Cleaning: Degreasing to remove oils and dirt.

- Pickling: Immersion in acid to remove mill scale and rust.

- Fluxing: A flux solution prepares the steel surface for bonding with zinc.

- Galvanizing Bath: The steel is fully immersed in a molten zinc bath (typically at 450°C). The zinc metallurgically bonds with the steel, forming multiple layers of zinc-iron alloy and a pure zinc outer layer.

- Cooling & Inspection: After removal from the bath, the grating cools. The galvanized coating thickness is then meticulously checked using magnetic gauges to ensure it meets international standards like ASTM A123/A123M, guaranteeing long-term protection against rust.

This galvanization process provides a sacrificial layer that protects the steel even if scratched, offering significantly longer service life compared to painted or untreated grating, often exceeding 20 years in typical industrial environments. This contributes significantly to the total cost of ownership (TCO) reduction.

Finishing & Packaging

The finished, galvanized grating panels are inspected one last time, then bundled and packaged for secure transportation. Proper packaging prevents damage during transit and facilitates easy handling at the project site.

Application Scenarios and Technical Advantages of **Steel Grating**

The versatility of steel grating makes it indispensable across a multitude of industries and applications. Its unique combination of strength, open area, and anti-slip properties provides significant advantages:

- Industrial Walkways and Platforms: In power plants, chemical factories, refineries, and manufacturing facilities, steel grating provides safe, stable, and well-ventilated walking surfaces for personnel. Its open design allows for light and air circulation, reducing the need for additional lighting and ventilation systems, leading to energy savings.

- Stair Treads: Specifically fabricated grating panels with nosing and end plates are used for industrial staircases, offering excellent grip and durability.

- Drainage Covers: For trenches, sumps, and culverts in municipal infrastructure, airports, ports, and industrial sites, metal grating serves as robust, load-bearing covers that efficiently drain liquids and prevent debris accumulation while remaining accessible for maintenance. Its high strength means it can withstand vehicle traffic.

- Mezzanines and Catwalks: Creating additional floor space in warehouses and factories, steel grating mezzanines are lightweight yet strong, allowing light to pass through to the lower level.

- Security Fencing and Screens: Heavy-duty grating can be used for robust security barriers or architectural screens where ventilation and visibility are desired.

- Ventilation Grilles: For HVAC systems or areas requiring significant airflow, grating can serve as robust and aesthetically pleasing grilles.

Key Advantages:

- High Strength-to-Weight Ratio: Provides robust load-bearing capabilities without excessive weight, simplifying installation and reducing structural load on supporting frameworks.

- Excellent Ventilation and Light Penetration: The open mesh design allows for free flow of air, heat, and light, contributing to a safer and more energy-efficient environment. This reduces HVAC costs and improves visibility.

- Superior Anti-Slip Properties: Especially with serrated options, steel grating offers reliable footing in wet, oily, or icy conditions, significantly enhancing worker safety and reducing slip-and-fall incidents, a critical aspect for OSHA compliance.

- Corrosion Resistance: Hot-dip galvanization provides a durable zinc coating that protects against rust and corrosive elements, extending the product's lifespan and reducing maintenance costs. This is particularly vital in marine, chemical, or wastewater treatment plants.

- Low Maintenance: Once installed, galvanized metal grating requires minimal upkeep, primarily occasional cleaning, due to its robust construction and corrosion-resistant finish.

- Long Lifespan: With proper material selection and manufacturing, bar grating can last for decades, offering a superior return on investment compared to alternative flooring solutions.

Technical Superiority of DQ Fence's Steel Bar Grate

At DQ Fence, our commitment to engineering excellence positions our Steel Bar Grate as a leading choice in the market for steel grating for sale. We differentiate ourselves through:

- Precision Manufacturing: Utilizing state-of-the-art electro-forged welding machinery ensures consistent quality, exact mesh sizes, and superior joint strength that surpasses conventional welding methods. This precision minimizes warping and improves installation efficiency.

- Premium Material Sourcing: We strictly use certified high-grade carbon steel (e.g., Q235B, equivalent to ASTM A36), ensuring the fundamental strength and durability of every panel. Material test certificates are available upon request.

- Robust Hot-Dip Galvanization: Our galvanizing process adheres strictly to ASTM A123/A123M, guaranteeing a thick, uniform zinc coating that provides maximum protection against corrosion, even in harsh industrial or marine environments. This commitment to coating thickness translates directly into a longer service life and reduced lifecycle costs for our clients.

- Adherence to International Standards: Our products are designed and manufactured in compliance with leading international standards such as ANSI/NAAMM MBG 531-09 (North American Association of Metal Grating Manufacturers), AS1657 (Australian Standards for Fixed Platforms, Walkways, Stairways, and Ladders), BS4592 (British Standard for Industrial Flooring), and China's YB/T4001.1-2007, ensuring global applicability and recognized quality.

- Versatile Customization: While we offer standard sizes, our strength lies in providing tailored solutions for complex projects. Whether it's unique panel shapes, specific cut-outs for pipes or equipment, or specialized load requirements, our engineering team works closely with clients to deliver precise custom solutions.

Manufacturer Comparison: Choosing the Right Partner for Your **Metal Grating** Needs

When seeking steel grating for sale, comparing manufacturers is crucial. While price is a factor, it should not overshadow quality, reliability, and service. Here’s a comparison framework to guide your decision-making, highlighting what a reputable manufacturer like DQ Fence prioritizes:

Table 3: Key Criteria for Manufacturer Comparison

| Criterion | Standard/Desired Practice | Why It Matters for Your Project |

|---|---|---|

| Manufacturing Process | Electro-forged welding for steel grating (preferred over manual welding for consistency) | Ensures uniform strength, rigidity, and durability; prevents panel distortion under load. |

| Material Quality & Traceability | Use of certified prime steel (e.g., ASTM A36, Q235B) with material test certificates. | Guarantees the product's fundamental strength and compliance with design specifications. |

| Certifications & Standards | ISO 9001:2015, adherence to ASTM, ANSI/NAAMM, BS, AS standards. | Indicates commitment to quality management systems and recognized performance benchmarks. Crucial for project acceptance. |

| Corrosion Protection | Hot-dip galvanization to ASTM A123/A123M minimum (average coating thickness specified). | Directly impacts product lifespan, reduces maintenance, and ensures long-term performance in corrosive environments. |

| Customization Capabilities | Ability to produce custom sizes, shapes, cut-outs, and specific load designs. | Essential for complex projects, minimizing on-site fabrication and ensuring a perfect fit. |

| Engineering & Design Support | Availability of technical team for load calculations, drawings, and project consultation. | Ensures optimal and safe design, saving time and preventing costly errors. |

| Delivery Lead Times & Logistics | Realistic lead times, efficient logistics, and global shipping experience. | Minimizes project delays and ensures timely availability of materials. |

| Warranty & After-Sales Support | Clear warranty statement (e.g., 10-year anti-corrosion), responsive customer service. | Provides peace of mind and support for any issues post-delivery or during product lifespan. |

| Project Experience & Track Record | Portfolio of successful projects in relevant industries, client testimonials. | Demonstrates proven capability and understanding of specific industry needs. |

Customization Solutions for Unique **Steel Grating** Requirements

Every industrial project has unique demands. At DQ Fence, we understand that off-the-shelf solutions may not always suffice. Our robust engineering and manufacturing capabilities allow us to offer comprehensive customization for steel grating for sale, ensuring your specific project needs are met with precision. Our customization options include:

- Tailored Dimensions and Shapes: From irregular panel shapes to curved grating and special angles, we can fabricate grating to fit complex architectural designs or industrial layouts.

- Precision Cut-Outs and Notches: Integration of cut-outs for pipes, columns, machinery, or access points are fabricated in our factory, ensuring a perfect fit and reducing costly on-site modifications.

- Specific Load Requirements: Based on your project's anticipated load-bearing needs (e.g., pedestrian, light vehicle, heavy vehicle), we can adjust bearing bar sizes, spacing, and material grades to meet required deflection limits and safety factors.

- Special Surface Treatments: Beyond hot-dip galvanization, we can discuss other coating options if specific environmental or aesthetic needs arise.

- Fabricated End Connections: Custom end plates, clips, or anchoring systems can be pre-welded or designed for ease of installation on specific support structures.

- Integrated Solutions: We can provide complete solutions including stair treads with nosings, trench covers with frames, and custom grating panels with toe plates for enhanced safety.

Our dedicated engineering team collaborates closely with clients from design conceptualization through to production, providing detailed shop drawings, load tables, and technical advice to ensure the customized bar grating solution is both functional and cost-effective.

Real-World Application Cases: DQ Fence **Steel Grating** in Action

The versatility and durability of DQ Fence's steel grating are best demonstrated through its successful deployment in diverse, demanding environments globally. Our steel grating for sale has been integral to enhancing safety, efficiency, and longevity across various industrial sectors:

Case Study 1: Oil & Gas Offshore Platform - North Sea

Challenge: An offshore oil platform required resilient, high-strength walkways and work platforms that could withstand extreme weather conditions, corrosive saltwater environments, and heavy operational loads. Traditional materials quickly deteriorated, leading to frequent maintenance and safety concerns.

Solution: DQ Fence supplied thousands of square meters of heavy-duty steel grating with a specific bearing bar configuration (e.g., 50x5mm at 30mm spacing) and extra-thick hot-dip galvanization (conforming to a higher zinc coating mass than standard ASTM A123). The serrated surface was chosen for superior anti-slip properties on wet and icy decks.

Outcome: The grating provided exceptional load capacity for equipment and personnel, and its robust galvanization significantly extended the service life beyond previous solutions, dramatically reducing maintenance downtime and enhancing worker safety in a critical environment. The improved light penetration also boosted visibility on the lower decks.

Case Study 2: Major Power Generation Plant - Texas, USA

Challenge: A large thermal power plant needed durable, heat-resistant, and high-ventilation flooring for boiler rooms, turbine halls, and catwalks where high temperatures and constant foot traffic were present. The existing flooring was prone to buckling and required frequent repairs.

Solution: DQ Fence provided custom-sized, electro-forged steel grating panels (e.g., 40x5mm at 40mm spacing) with precise cut-outs for machinery and pipework. The open mesh design allowed for optimal heat dissipation and air circulation, crucial for operational efficiency and worker comfort in high-temperature zones.

Outcome: The new grating systems vastly improved ventilation, leading to better temperature regulation within the facility. Its high load capacity and exceptional durability have significantly reduced maintenance requirements, providing a safe and stable working environment for engineers and technicians for years to come.

Case Study 3: Municipal Wastewater Treatment Facility - Coastal City

Challenge: A wastewater treatment plant required robust trench covers and access platforms that could withstand highly corrosive chemical environments (acidic/alkaline wastewater, airborne chemicals) and constant pedestrian traffic. Prior grating solutions corroded rapidly.

Solution: DQ Fence recommended and supplied galvanized metal grating specifically manufactured with thicker bearing bars and an enhanced hot-dip galvanized coating (meeting ISO 1461 standards). Specific panels were designed for easy removal for maintenance access to the treatment tanks.

Outcome: The superior corrosion resistance of the hot-dip galvanized coating has proven highly effective in the aggressive environment, offering an expected lifespan far exceeding previous installations. The secure, anti-slip surface ensures worker safety during routine inspections and operations, demonstrating the long-term value of our steel grating for sale in challenging conditions.

Quality Assurance, Certifications, and Trustworthiness (EEAT)

At DQ Fence, our commitment to quality is not just a promise; it's embedded in every stage of our operations. We understand that for industrial clients, trust is built on demonstrable expertise, experience, authority, and reliability (EEAT). Here’s how we uphold these pillars for our steel grating for sale:

Expertise & Authoritativeness:

- Industry Certifications: We operate under an ISO 9001:2015 certified Quality Management System, ensuring consistent product quality and process efficiency. Our products regularly meet or exceed international standards such as ASTM (American Society for Testing and Materials), ANSI/NAAMM MBG 531-09 (North American Association of Metal Grating Manufacturers), BS 4592 (British Standards), and AS 1657 (Australian Standards).

- Rigorous Testing: Every batch of grating undergoes stringent in-house testing, including load-bearing capacity tests, deflection tests, and galvanized coating thickness measurements (e.g., using eddy current or magnetic induction devices). Third-party testing can also be arranged upon request.

- Technical Prowess: Our engineering team boasts decades of combined experience in industrial grating design and application. They are equipped to provide detailed technical specifications, CAD drawings, and load tables, ensuring the optimal solution for your project.

- Authoritative Citations: Our manufacturing processes and product specifications are aligned with the best practices recommended by industry bodies and technical journals focused on steel fabrication and structural engineering. We regularly consult publications from organizations like the American Institute of Steel Construction (AISC) and galvanized steel associations to stay at the forefront of material science and application.

Experience:

- Proven Track Record: With over 15 years in the manufacturing and supply of steel grating solutions, DQ Fence has successfully completed thousands of projects globally, ranging from critical infrastructure to large-scale industrial facilities.

- Customer-Centric Approach: Our experience has taught us the importance of understanding specific client needs, providing tailored solutions, and offering proactive communication throughout the project lifecycle. We have a dedicated team for post-sales support, ensuring customer satisfaction.

- Feedback Integration: We actively solicit and integrate customer feedback into our product development and service improvements, constantly refining our offerings based on real-world application experience.

Trustworthiness:

- Transparent Processes: We provide full transparency on our material sourcing, manufacturing processes, and quality control procedures. Clients are welcome to visit our facilities or arrange for independent inspections.

- Comprehensive Warranty: All our hot-dip galvanized steel grating for sale products come with a comprehensive 10-year anti-corrosion warranty, subject to standard conditions of use and maintenance. This demonstrates our confidence in product longevity.

- Reliable Delivery & Support: We offer clear delivery schedules and robust logistics support to ensure on-time delivery. Our dedicated customer support team is available to assist with any queries, from technical specifications to installation guidance, ensuring a smooth project experience from order to installation and beyond.

- Secure Transactions: We employ secure payment gateways and adhere to international business practices, ensuring the safety and integrity of all transactions.

Delivery Cycle, Warranty, and Customer Support

At DQ Fence, we streamline the process from order to installation, ensuring efficiency and reliability for our clients seeking steel grating for sale.

- Delivery Cycle:

- Standard Products: Typically 2-4 weeks from order confirmation, depending on order volume and current production schedule.

- Customized Solutions: 4-8 weeks, subject to complexity of design and specific fabrication requirements. Our team provides precise lead times upon detailed project scope.

- Logistics: We collaborate with trusted global shipping partners to ensure secure and timely delivery to your project site, whether domestic or international. We handle all necessary documentation for smooth customs clearance.

- Warranty Commitment:

- We proudly offer a 10-year anti-corrosion warranty on all our hot-dip galvanized steel grating products. This warranty covers defects in the galvanization process that lead to premature rust under normal operating conditions and proper maintenance.

- Our commitment underscores the superior quality of our hot-dip galvanization process, which significantly extends the product's lifespan and reduces lifecycle costs.

- Customer Support:

- Pre-Sales Consultation: Our expert sales and engineering teams are available to provide comprehensive technical advice, help with product selection, load calculations, and offer design optimization suggestions.

- Order Tracking: Clients receive regular updates on their order status, from manufacturing progress to shipping details.

- Post-Sales Assistance: Beyond delivery, our support continues. We provide installation guidance, maintenance tips, and are readily available to address any questions or concerns that may arise after product delivery and installation.

- Dedicated Project Managers: For large or complex projects, a dedicated project manager is assigned to ensure seamless coordination and communication throughout the entire process.

Professional FAQ: Deep Dive into **Steel Grating** Technicalities

Plain steel grating has a smooth top surface on its bearing bars. Serrated steel grating, on the other hand, features notches or teeth cut into the top edge of the bearing bars. The primary difference lies in anti-slip properties: serrated grating provides significantly enhanced traction, making it ideal for environments where slip hazards (like water, oil, snow, or grease) are present, such as offshore platforms, wastewater treatment plants, or industrial walkways.

The load capacity of bar grating is primarily determined by the size (depth and thickness) and spacing of the bearing bars, as well as the material's yield strength. Industry standards, such as ANSI/NAAMM MBG 531-09 (North American Association of Metal Grating Manufacturers), provide detailed tables and calculation methods for load tables and permissible deflections based on various grating configurations. These standards ensure safe and reliable performance under specified loads.

Hot-dip galvanization (HDG) offers superior corrosion resistance compared to paint or prime coatings. During HDG, a metallurgical bond forms between the steel and the zinc, creating a highly durable and sacrificial coating that protects the steel even if scratched. It provides complete coverage (inside and out), is highly resistant to abrasion, and significantly extends the lifespan of the metal grating, leading to lower long-term maintenance costs and a reduced total cost of ownership. It adheres to standards like ASTM A123/A123M or ISO 1461.

Absolutely. Reputable manufacturers like DQ Fence offer extensive customization. This includes custom panel dimensions (length and width), specific bearing bar and cross bar spacing, varied bar sizes for unique load requirements, intricate cut-outs for pipes or equipment, custom shapes (e.g., circular, triangular), and specialized surface treatments. Customization ensures a perfect fit, minimizes on-site fabrication, and optimizes performance for the specific application.

The lifespan of hot-dip galvanized steel grating is highly dependent on the thickness of the zinc coating and the corrosivity of the environment. In typical atmospheric industrial environments, a coating conforming to ASTM A123/A123M can provide protection for 20 to 50 years or even more. In more aggressive environments (e.g., highly acidic, marine), the lifespan may be shorter but still significantly longer than non-galvanized alternatives. Proper initial coating thickness and periodic inspection contribute to its longevity.

Steel grating can be installed using various methods, typically secured to supporting structures (e.g., steel beams). Common methods include:

- Grating Clips: These are the most common and versatile. Clips (saddle clips, G-clips) bolt the grating to the support structure, allowing for easy removal or adjustment.

- Welding: For permanent installations or very heavy-duty applications, the grating can be welded directly to the supporting steelwork.

- Bolting: Similar to clips, but using specific bolted connections, often seen with custom fabricated end plates.

The choice depends on the load, vibration, environment, and need for future access.

Steel grating for sale is a cornerstone in numerous heavy industries due to its durability and functionality. Key sectors include: Petrochemical and Oil & Gas (refineries, offshore rigs), Power Generation (power plants, substations), Metallurgy (steel mills, foundries), Chemical Plants, Wastewater Treatment Plants, Food Processing Facilities (often stainless steel), Mining, Shipbuilding, Architectural Projects (facades, sun shades), and general industrial and commercial facilities for walkways, platforms, and drainage systems.

Conclusion: Investing in Excellence with DQ Fence **Steel Bar Grate**

The demand for high-performance steel grating for sale is a testament to its indispensable role in modern industrial and infrastructural development. From enhancing safety and operational efficiency to ensuring long-term structural integrity in the most challenging environments, a well-chosen steel grating solution offers unparalleled value. At DQ Fence, our unwavering commitment to quality, precision engineering, and comprehensive customer support ensures that our Steel Bar Grate stands as a benchmark for excellence.

By focusing on superior materials, advanced manufacturing processes like electro-forged welding, and rigorous quality control complemented by robust hot-dip galvanization, we provide a product that not only meets but often exceeds international standards. Our ability to offer extensive customization, coupled with our proven track record in diverse application scenarios, positions us as a trusted partner for your industrial grating needs. Choosing DQ Fence means investing in a solution that promises durability, safety, and a lower total cost of ownership, driving the success and longevity of your projects.

References and Further Reading:

- Grand View Research. (2023). *Industrial Flooring Market Size, Share & Trends Analysis Report, 2023-2030*. https://www.grandviewresearch.com/industry-analysis/industrial-flooring-market

- American Galvanizers Association. (2022). *Durability of Hot-Dip Galvanizing*. https://www.galvanizeit.org/hot-dip-galvanizing/what-is-hot-dip-galvanizing/durability

- NAAMM (National Association of Architectural Metal Manufacturers). (2009). *Metal Bar Grating Manual (MBG 531-09)*. (Specific public link not available for full manual, but often referenced in industry forums and technical documents.)

- SteelConstruction.info. *Design of Steel Grating*. https://www.steelconstruction.info/Design_of_steel_grating

- Corrosionpedia. *Hot-Dip Galvanization*. https://www.corrosionpedia.com/definition/651/hot-dip-galvanization

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025