- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Aug . 02, 2025 08:40 Back to list

Secure Wholesale 358 Anti-Climb Fence - Buy Now!

The wholesale 358 anti-climb fence market is accelerating at a global scale due to stringent security requirements in critical infrastructure sectors. In this comprehensive guide, we’ll analyze the latest industry trends, discuss technical parameters of 358 anti climb fence products—including pvc coated 358 anti climb fence and 358 mesh solutions—review leading manufacturers, and present real-world application scenarios. Data-backed comparisons, product diagrams, certification insights, and expert Q&A are provided to deliver the industry’s highest level of expertise and trust.

1. Industry Trends & Market Insights

- According to MarketResearchFuture, the global anti-climb fence market exceeded USD 1.1 billion in 2023, with a projected CAGR of 4.2% from 2024–2030.

- Growth drivers: increased threats to perimeter security, critical infrastructure expansion, and adoption of security enhancement protocols (ISO/IEC 27001).

- End-user segments: Transportation, Power Utilities, Oil & Gas, Correctional Facilities, Industrial Parks, and Water Treatment.

- Technological shift: Rising demand for PVC coated 358 mesh solutions due to superior anti-corrosion and low maintenance cost.

2. Technical Specifications & Parameter Comparison

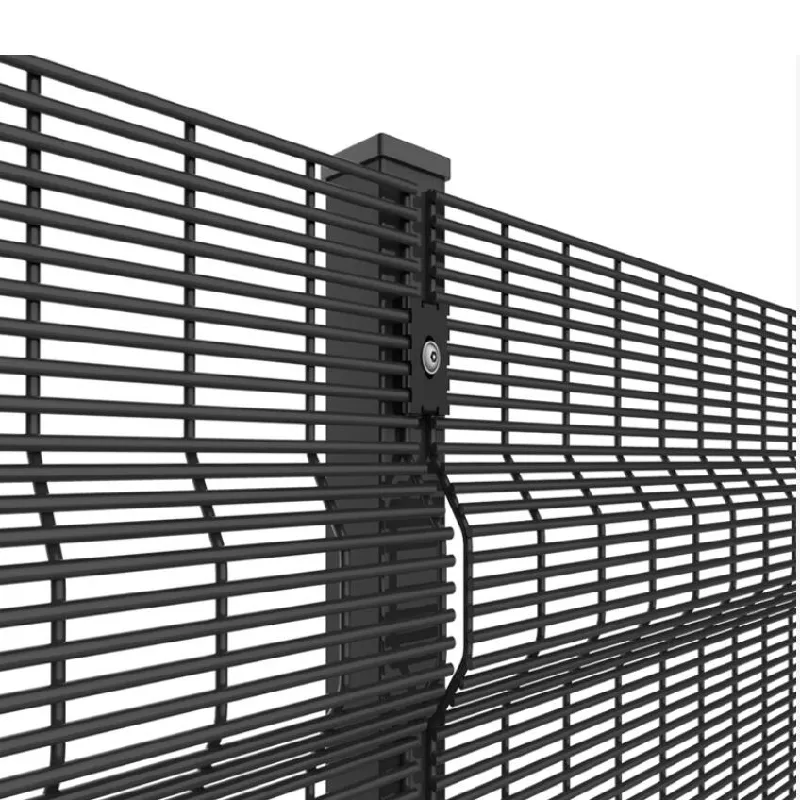

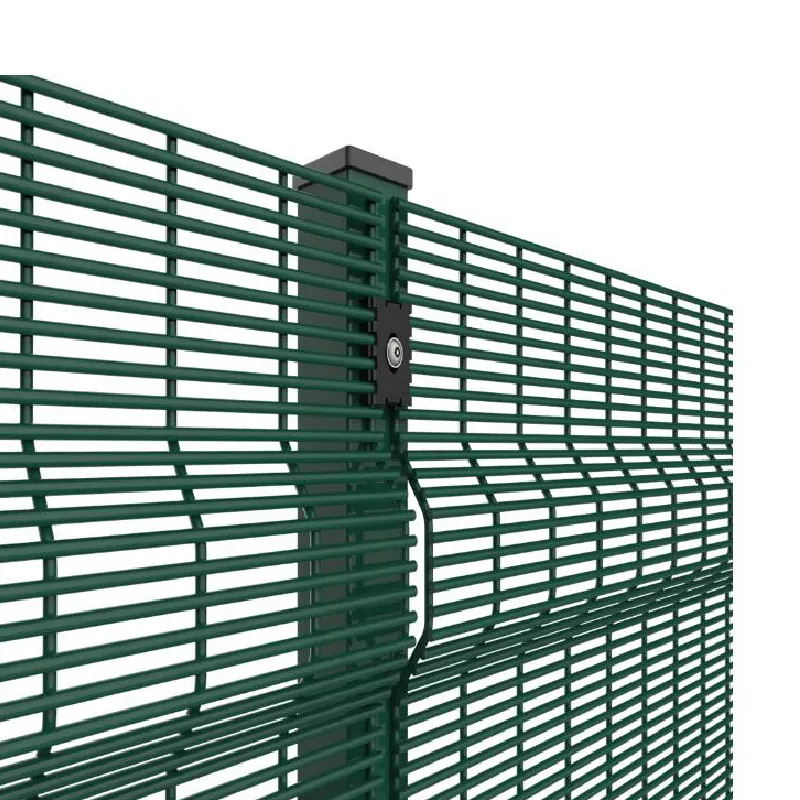

The 358 anti climb fence is characterized by its superior mesh design—"358" stands for a mesh measuring 3" × 0.5" × 8 gauge (76.2mm × 12.7mm × 4mm) and is engineered for maximum resistance against cutting, climbing, and penetration.

| Specification | Description |

|---|---|

| Mesh Aperture | 76.2mm × 12.7mm (3” × 0.5”) |

| Wire Diameter | 4.0mm (8 gauge) |

| Panel Height | 1.8m, 2.0m, 2.4m, 3.0m (customizable) |

| Panel Width | 2.0m – 2.5m |

| Coating Options | Galvanized, Powder Coated, PVC Coated |

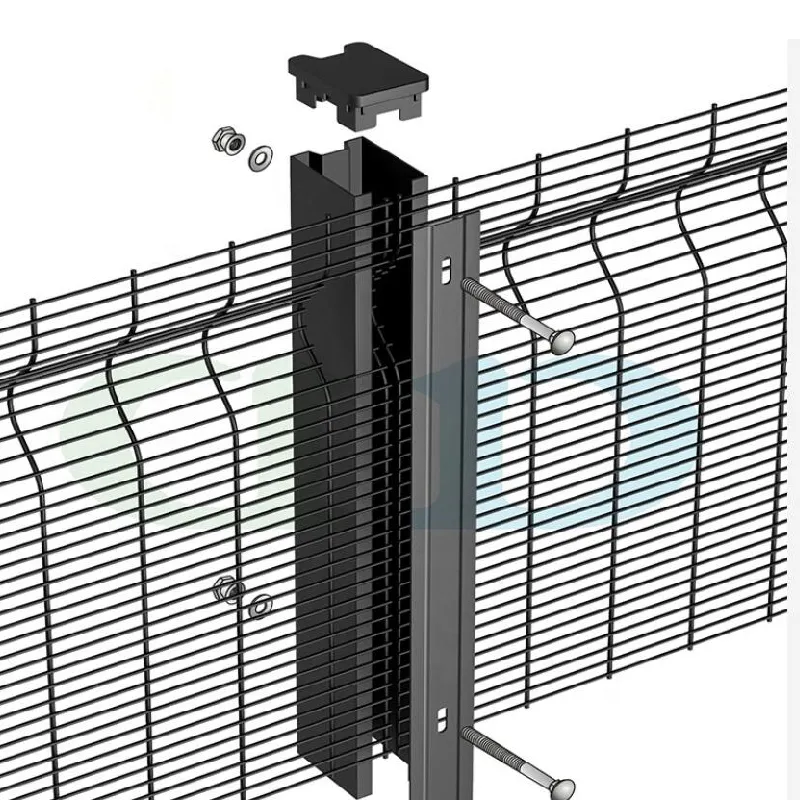

| Post Type | 60×60mm / 80×60mm RHS (Rectangular Hollow Section) |

| Weld Strength | >70% of wire tensile strength |

| Anti-Corrosion Performance | >2000 hours Salt Spray (ASTM B117 tested for PVC/galv. coat) |

| Compliance | ISO 9001:2015, EN 10244-2, ANSI Standard, RoHS, CE |

| Coating Type | Salt Spray Resistance | UV Protection | Color Options | Expected Service Life |

|---|---|---|---|---|

| PVC Coated 358 Anti Climb Fence | > 2,000 hours | ✓ | Green, Black, Custom | 15+ Years |

| Galvanized | 1,000 – 1,200 hours | ✗ | Metallic Only | 10+ Years |

| Powder Coated | 1,500 – 1,600 hours | ✓ | Diverse | 12+ Years |

3. 358 Mesh: Structure & Unique Properties

The 358 mesh structure provides maximum security by minimizing the potential for toeholds or handholds. It’s also known as “prison mesh” due to its use in correctional facilities. Welded at each intersection, 358 mesh provides high rigidity and anti-burrowing capacity.

- Anti-Cutting: 4mm diameter wires resist bolt cutters (tensile strength >550 MPa).

- Anti-Climb: Aperture tightly spaced (12.7mm); fingers/toes cannot fit.

- Visual Transparency: Allows clear CCTV monitoring—ideal for security systems.

4. Manufacturing Process: Wholesale 358 Anti-Climb Fence

- Galvanizing (EN 10244-2: Zinc coating ≥250g/m²)

- PVC/Polyester powder coating (ASTM D3359 Adhesion Test)

5. Application Scenarios & Industry Solutions

Wholesale 358 anti-climb fence is chosen by numerous industries for its unique balance of security and transparency. See how key sectors utilize these solutions:

- Critical Infrastructures (Power, Petrochemical, Waterworks): 93% of surveyed sites in the US/EU specify 358 anti-climb fence for perimeter security (source: Security Magazine).

- Correctional Facilities & Prisons: The original "prison mesh" application—anti-burrowing, anti-cutting, C3 anti-corrosion grade.

- Transportation Hubs (Airports, Rail): Installed along perimeters for anti-climb deterrence; compatible with vibration and IR sensor arrays.

- Industrial Parks: Used for property protection and clear visual area monitoring.

6. Leading Manufacturer Comparison – Who Delivers the Best?

| Brand/Manufacturer | Certifications | Service Years | Customization | Major Markets |

|---|---|---|---|---|

| DQFENCE (DQFENCE) | ISO 9001, EN 10244-2, CE | 20+ | Yes: Size, Color, Coating | Global (NA/EU/ME/SEA) |

| Bekaert Fencing | ISO 9001, EN Standards | 30+ | Yes | Europe, Americas |

| Betafence | ISO 9001, ISO 14001, CE | 135+ | Yes | World |

| BRC Fence | ISO 9001, SIRIM | 25+ | Partial | Asia-Pacific |

DQFENCE leads for both standard and rapid custom delivery, with robust technical support and globally recognized certifications.

7. Customization & OEM Design Capabilities

- Mesh Density: 358/356/3510 Mesh options; panel heights up to 5 meters.

- PVC Coating: Select thickness (0.6–1.2mm) and color (RAL6005, 9005, etc.).

- Integrated Security Options: Razor wire, anti-tamper bolts, vibration sensors.

- Project Support: CAD drawings, wind/snow/impact load calculation upon request.

8. Real-World Application Cases & Client Feedback

- PetroChina Sichuan Refinery (Phase 3, 2023): 2,400 meters of 358 mesh fence installed. No breach incidents detected, corrosion tested (ISO 9227) for 24 months—with <0.2% rust spots in humid alkaline environment.

- Singapore Metro Expansion: 358 anti-climb security fence along 14 km perimeter; zero climb incidents since 2022. Integrated with IR motion alarm, easy for CCTV surveillance.

- Italy Correctional Center Retrofit: Old fence replaced with pvc coated 358 anti climb fence. Improved camera visibility (+30% night IR transmittance) and solved vandalism issues.

— Security Director, Major East Asia Airport (2024)

9. Compliance, Certifications & Customer Support

- Certification: All DQFENCE 358 anti climb fence products are produced to ISO 9001:2015 and ANSI standards, with compliance to European CE and RoHS directives.

- Warranty: 10-year anti-corrosion warranty for standard panels. Extended lifetime support for OEM/bespoke projects.

- Support: Professional engineering support, 3D/2D design assistance, and rapid after-sales response within 12 hours (global).

- Delivery: Standard product: 7–15 days; Customized project: 15–25 days (by sea/rail/road/air as required).

10. Expert FAQ on 358 Anti Climb Fence

Q1: What’s the typical wire material for wholesale 358 anti-climb fence?

A: Industrial grade low carbon steel (Q235/Q195); for high security, optional stainless steel grades available.

Q2: How is the coating thickness for pvc coated 358 anti climb fence controlled?

A: PVC/polyester thickness: 0.6–1.2mm (ASTM D3359-compliant). Thickness is tested per EN 10244-2.

Q3: What installation standards should I follow?

A: EN 1722 for fence-post concrete, ANSI 280 for panel alignment, and ISO 1461 for hot-dip galvanized.

Q4: What dimensional tolerances apply to 358 mesh?

A: Mesh ±3mm, panel height/width ±5mm; Weld shear strength >70% wire ultimate (lab validated, ISO 6892-1).

Q5: What security add-ons are available?

A: Razor wire topping, anti-dig mesh skirt, vibration or PIR alarms can be integrated.

Q6: How does 358 mesh perform in coastal/corrosive environments?

A: Superior—PVDF/PVC coating plus heavy galvanizing (min. 250g/m²) gives 12–18 years’ resistance (5000+ hours salt spray per ISO 9227).

Q7: What customer support is available internationally?

A: 24/7 multi-language support, remote design review, and site engineer dispatch for major projects.

For more on the global supply chain, technical developments, or to discuss your needs for wholesale 358 anti-climb fence, contact DQFENCE for a technical proposal or complimentary engineering consultation!

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025