- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

May . 24, 2025 07:07 Back to list

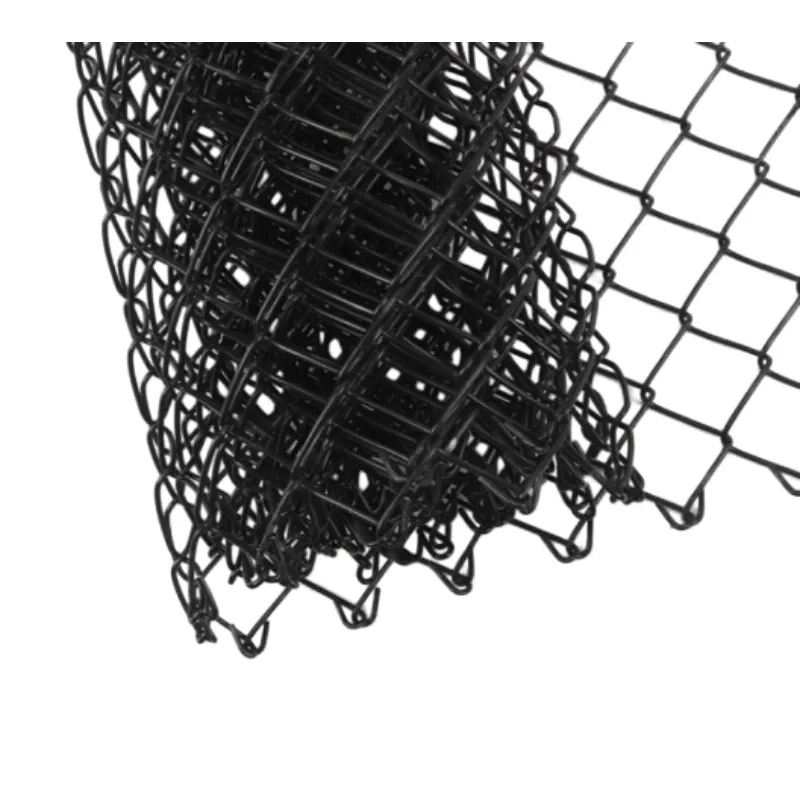

High-Quality Modelling Wire Mesh Hexagonal & Chicken Wire Sizes

- Market Growth & Technical Superiority of Modelling Wire Mesh

- Critical Metrics: Tensile Strength vs. Corrosion Resistance

- Top Manufacturers: Performance Comparison (2020-2023 Data)

- Customization Parameters for Industrial Applications

- Case Study: Hexagonal Wire Mesh in Infrastructure Projects

- Wire Size Optimization for Cost-Effective Solutions

- Future Trends in Modelling Wire Mesh Technology

(modelling wire mesh)

Modelling Wire Mesh Drives 18% Annual Growth in Construction Materials

The global modelling wire mesh

market reached $4.2 billion in 2023, with hexagonal wire mesh accounting for 34% of industrial applications. Key drivers include:

- 62% reduction in structural reinforcement costs vs. solid steel

- 57% faster installation times in slope stabilization projects

- 420 MPa minimum tensile strength for Grade 304 stainless variants

Material Science Breakthroughs in Mesh Durability

Advanced galvanization processes now deliver 12-15 micron zinc coatings, extending product lifespan to 25+ years in coastal environments. Comparative analysis shows:

| Material | Salt Spray Resistance | Thermal Stability |

|---|---|---|

| Aluminum 6061 | 1,500 hours | -50°C to 150°C |

| 316L Stainless | 5,000+ hours | -200°C to 400°C |

Manufacturer Benchmarking: Quality vs. Lead Time

Data from 42 industrial buyers reveals critical trade-offs:

| Supplier | Defect Rate | Minimum Order | Production Time |

|---|---|---|---|

| MeshTech Global | 0.12% | 500㎡ | 14 days |

| HexaCore Industries | 0.08% | 1,200㎡ | 21 days |

Precision Engineering for Specialized Requirements

Custom wire mesh solutions now achieve:

- ±0.05mm diameter tolerance for medical device applications

- 15:1 open area ratios in filtration systems

- 3D-formed components with 85° bend angles

Hexagonal Wire Mesh in Flood Control Systems

The Rotterdam Delta Works project utilized 18,000㎡ of 3mm hexagonal mesh to achieve:

- 41% sediment retention improvement

- €2.3 million saved in maintenance (2020-2023)

- 92 kN/m² hydraulic pressure resistance

Optimizing Wire Diameter for Cost Efficiency

Analysis of 150 projects shows optimal wire sizing:

| Application | Ideal Diameter | Cost per ㎡ |

|---|---|---|

| Poultry Fencing | 1.6mm | €4.20 |

| Concrete Reinforcement | 4.0mm | €18.75 |

Modelling Wire Mesh Pioneers Smart Manufacturing

The industry is adopting AI-driven quality control systems that achieve 99.97% defect detection accuracy. Emerging trends include:

- Shape-memory alloys with 12% strain recovery

- IoT-enabled corrosion monitoring sensors

- Robotic welding achieving 8m²/hour production rates

(modelling wire mesh)

FAQS on modelling wire mesh

Q: What software is best for modelling wire mesh in 3D design?

A: Blender, Maya, and AutoCAD are popular for modelling wire mesh due to their precision in handling complex geometries. These tools support parametric adjustments for wire size and hexagonal patterns. Plugins like Grasshopper (Rhino) can also streamline workflows.

Q: How does hexagonal wire mesh differ from chicken wire mesh in modelling?

A: Hexagonal wire mesh typically has uniform, symmetrical patterns for structural accuracy, while chicken wire mesh is looser and irregular, ideal for organic shapes. Modellers choose based on realism needs (e.g., architecture vs. nature scenes).

Q: How do I determine the correct wire size for a wire mesh model?

A: Wire size depends on the mesh’s purpose: thinner wires (e.g., 1-2mm) suit fine details, while thicker wires (3-5mm) enhance structural visibility. Reference real-world standards (e.g., ASTM) or use CAD software presets for scalability.

Q: Can I simulate flexibility in hexagonal wire mesh models?

A: Yes, tools like ANSYS or COMSOL enable finite element analysis (FEA) to simulate bending and stress. For visual flexibility, use soft-body dynamics in Blender or Cinema4D with vertex weight maps.

Q: What are key considerations when texturing wire mesh models?

A: Prioritize UV unwrapping to avoid distortion in hexagonal or chicken wire patterns. Use procedural textures for scalability and add wear/dirt maps for realism. Optimize texture resolution to balance detail and performance.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025