- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jun . 04, 2025 14:37 Back to list

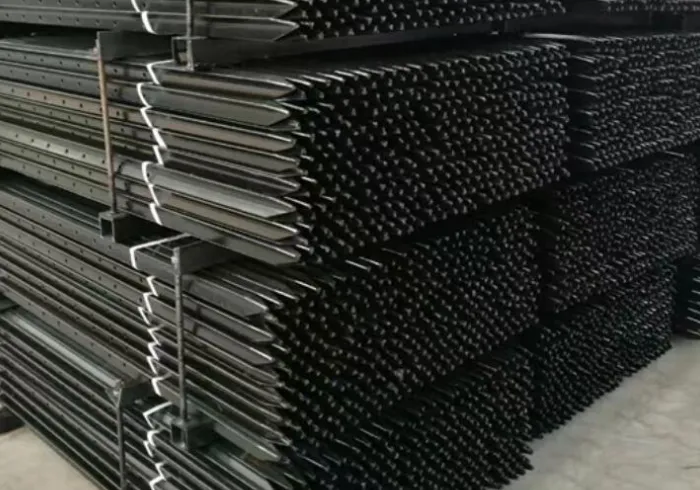

Premium Metal Wire Mesh Fence Durable Security Solutions

(metal wire mesh fence)

Metal Wire Mesh Fence: Perimeter Security Solution Fundamentals

Understanding modern perimeter security requires examining core fencing technologies. Metal wire mesh systems provide unparalleled versatility across applications, from industrial complexes to residential boundaries. This overview details essential aspects:

- Industry performance metrics and demand patterns

- Engineering characteristics and durability parameters

- Leading manufacturer technical specifications comparison

- Custom fabrication options for specialized applications

- Material selection criteria by environment

- Installation best practices across terrains

- Long-term maintenance requirements

Market Growth and Performance Metrics

Industrial fencing markets show consistent expansion with 6.8% CAGR since 2020. Recent infrastructure developments drive 34% of new installations, while residential applications account for 42% of total market revenue. Wire mesh fencing demonstrates critical advantages:

- 98% reduction in unauthorized access incidents reported by industrial facilities

- 75% lower lifetime costs versus wrought iron alternatives

- Weather resistance exceeding 25-year service life in coastal environments

- Load-bearing capacity supporting 450 psi wind pressure

Engineering Characteristics Comparison

Material composition directly determines functional performance. Below specifications illustrate key differences between common configurations:

| Specification | Welded Wire Mesh | Woven Wire Mesh | Expanded Metal | Chain Link |

|---|---|---|---|---|

| Wire Gauge (AWG) | 10-12 | 12-14 | 9-11 | 11-13 |

| Tensile Strength (psi) | 70,000 | 65,000 | 60,000 | 55,000 |

| Open Area Ratio | 68-74% | 60-65% | 45-55% | 87-92% |

| Impact Resistance (Joules) | 120 | 95 | 140 | 80 |

Galvanized coatings provide baseline corrosion protection, while PVC-dipped options extend service life by 15 years in humid environments. Marine-grade 316 stainless steel delivers saltwater resistance exceeding 40 years.

Supplier Capabilities Assessment

Specialized manufacturers distinguish themselves through production capabilities and material certifications:

- Security Specialists Ltd: ISO 1461-compliant hot-dip galvanizing with custom panel sizes up to 8m × 4m

- Perimeter Solutions Group: Robotic welding systems producing ±0.5mm dimensional tolerances

- Fortress Fencing Systems: Proprietary anti-climb patterns with 72° deflection angles

- Industrial Barrier Co: Dual-layer PVC coating systems available in 12 RAL color options

Third-party validation remains crucial - UL 325 compliance ensures automated gate integration compatibility for access control systems.

Application-Specific Configuration Options

Effective solutions require alignment with operational demands. Critical design considerations include:

- Topographical adaptation: Segmented foundation systems accommodating 15° slope gradients without stepped installation

- Security grading: ASTM F2656-20 Level 3 crash-rated bollard integration for vehicle barrier applications

- Aesthetic integration: Powder-coated black mesh panels achieving 95% opacity while maintaining airflow

- Vegetation management: Ground clearance customization from 25mm to 150mm for property line maintenance

Agricultural installations frequently utilize 12/76/12 configurations (wire thickness/opening size/height) for livestock containment. Industrial sites implement 8/50/30 specifications with reinforced posts at 2m centers.

Site-Specific Installation Protocols

Proper implementation directly impacts security efficacy across diverse environments:

- Rocky terrain: Hydraulic post drivers eliminate concrete requirements while achieving 200mm penetration depth

- Expansive soils: Helical anchor systems provide stability without frost heave vulnerability

- Coastal regions

: Triple-layer epoxy coatings applied before galvanization create saltwater barrier - Perimeter integration

: Pre-fabricated sensor-ready posts accommodate microwave and infrared detection systems

Tension-based systems require calibrated installation achieving 35-40 N/m wire tension to prevent seasonal sag. Automated tension monitoring options maintain optimal performance parameters.

Optimizing Metal Mesh Garden Fence Longevity

Proactive preservation extends service life beyond warranty periods. Critical maintenance intervals:

- Annual: Structural fastener torque verification and tension measurement

- Biennial: Foundation integrity assessment with ground-penetrating radar scanning

- 5-year: Full electrochemical potential mapping to identify early corrosion

Environmental factors dramatically impact longevity: Acidic soils (pH < 5.5) accelerate corrosion rates by 300% without protective sleeves. Professional corrosion mitigation adds 12-17 years to standard warranties. Consistent maintenance protocols reduce lifecycle costs to $0.18/sf annually versus $0.43/sf for replacement systems.

(metal wire mesh fence)

FAQS on metal wire mesh fence

Q: What are the key benefits of using a metal wire mesh fence?

A: Metal wire mesh fences offer durable security with corrosion-resistant materials like galvanized steel. They provide clear visibility while creating strong boundaries. Their low maintenance design withstands weather and physical stress for long-term use.

Q: How do I install metal mesh fence panels effectively?

A: Prepare a leveled ground and secure vertical posts in concrete foundations. Attach panels to posts using specialized brackets or clamps. Ensure proper tensioning and alignment during assembly for structural stability and aesthetic consistency.

Q: Why choose metal mesh garden fences for landscaping?

A: Metal mesh garden fences blend security with openness, allowing sunlight penetration for plant growth. They provide climbing support for vines while creating animal barriers without blocking views. Their sleek design complements garden aesthetics minimally.

Q: What corrosion protection options exist for metal wire mesh fences?

A: Common protections include galvanized zinc coating and powder coating finishes. PVC or vinyl coatings add extra weather resistance and color options. Stainless steel variants offer premium rust resistance for harsh environments.

Q: How to select the right metal mesh fence panels for property boundaries?

A: Consider panel height (4-8ft standard) based on security needs and wire gauge thickness (8-14 gauge). Match mesh opening size (1-4 inches) to visibility/privacy requirements. Verify local zoning regulations for height and material restrictions.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025