- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jul . 30, 2025 01:00 Back to list

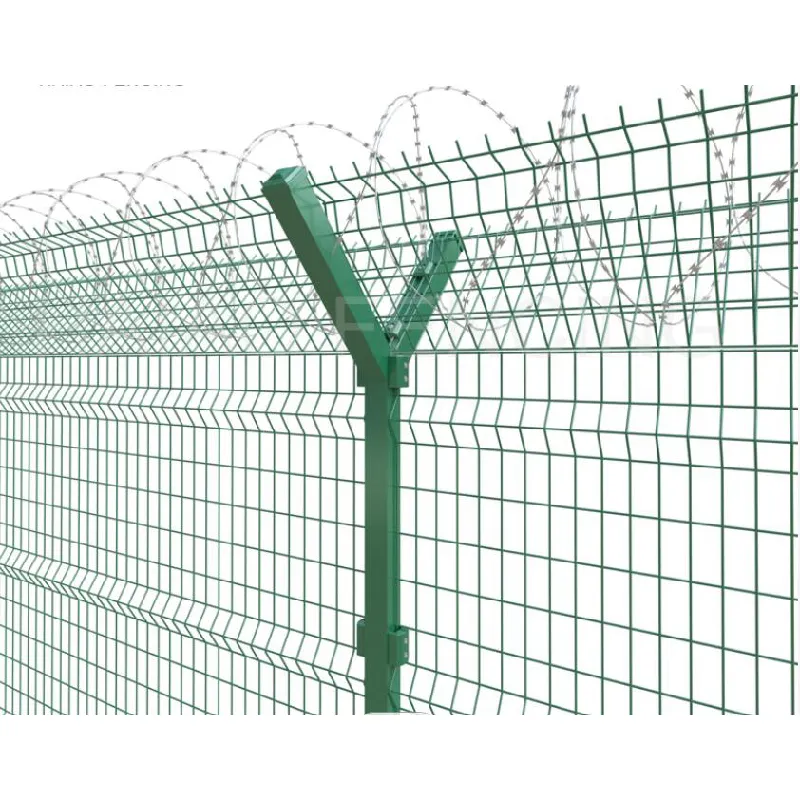

High-Security Airport Fence Solutions for Airports & Wholesale Supply

In the context of modern aviation security, the importance of airport fence and airport security fencing has never been more critical. As a cornerstone of perimeter security, airport fence systems deliver not only physical demarcation but also integrated anti-intrusion solutions that meet global safety standards. This in-depth resource explores market trends, technical parameters, manufacturing processes, application scenarios, and presents data-driven comparisons to guide procurement, engineering and security professionals.

- Market size: In 2023, the global airport perimeter security market exceeded USD 8.2 billion (source: MarketsandMarkets), with an annual CAGR of 7.4% projected through 2030.

- Regulatory landscape: Compliance with rigorous standards such as ICAO Doc 8973, ISO 1461, ANSI/ASTM F2781.

- Trend: Rapid adoption of advanced anti-climb designs, modular fencing, and smart security integration (fiber optics, vibration sensors).

- Procurement: Rising preference for wholesale airport fence solutions to optimize logistics and cost.

| Item | Airport Fence | Brand A | Brand B | Industry Standard |

|---|---|---|---|---|

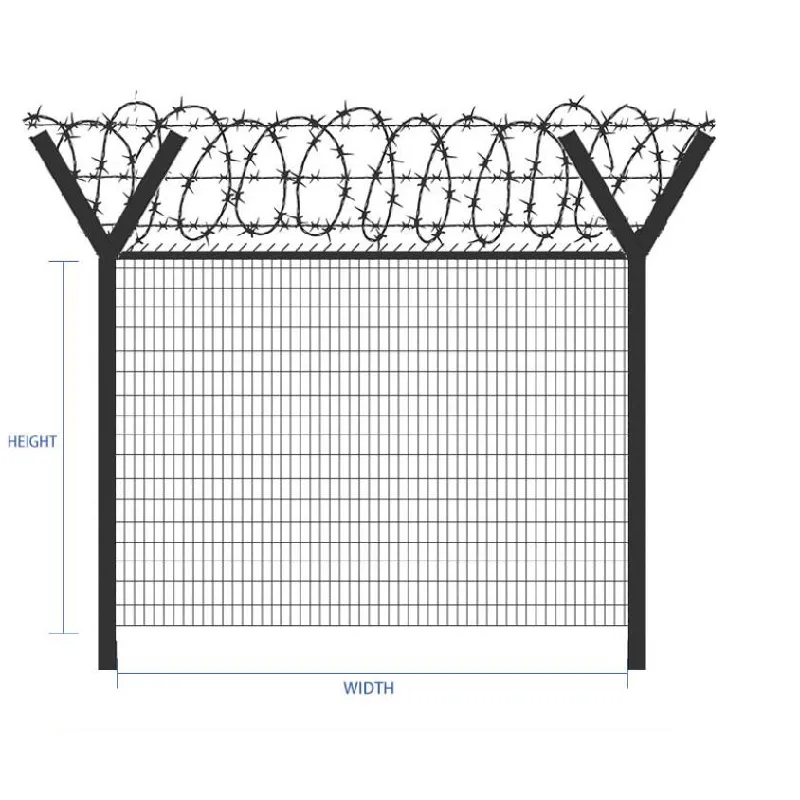

| Fence Height (m) | 2.4 / 2.7 / 3.0 | 2.1 / 2.4 | 2.0 / 2.7 | ≥2.4 |

| Mesh Opening (mm) | 50×100 / 75×150 | 50×150 | 60×120 | ≤75×150 |

| Wire Diameter (mm) | 4.0–6.0 | 4.0–5.0 | 3.5–4.5 | ≥4.0 |

| Material | Q235 Galvanized Steel / 304 Stainless Steel | Galvanized Iron | Carbon Steel | ISO/EN-approved Metals |

| Finish | Galvanized + PVC/PE Powder Coating | Hot-dip Galvanized | PVC Coating | ISO 1461/9227 |

| Corrosion Resistance | Salt-spray 1000h+ | Salt-spray 600h | Salt-spray 700h | ISO 9227:2017 |

| Service Life (years) | 25–30 | 15–20 | 10–15 | ≥15 |

| Anti-climb Design | V-top Y-post, Concertina Razor Wire | V-top only | No | ICAO / ASTM F2781 |

The above comparison demonstrates that airport fence systems offer superior material and anti-corrosion performance, meeting strict ISO / ANSI standards and providing extended service life even in harsh environments, critical for fence airport applications.

→Step-by-step: Each process node boosts structural consistency and performance.

- Chemical Stability: Hot-dip galvanized + PVC delivers >1000h salt spray test endurance (ISO 9227), suitable for petrochemical zones and coastal airports.

- Safety by Design: V/Y top prevents external intrusion and escape. Mesh design inhibits foot/handhold, compliant with ICAO anti-climb criteria.

- Custom Panel Options: Color (RAL palette), mesh size, panel thickness, height, branding available for project-specific adaptation.

- Application Sectors: Airport fence solutions are widely deployed in airports, energy plants, water management, metallurgy yards, defense bases, and critical infrastructure.

- Smart Technology Upgrade: Optional integration of vibration/fiber sensors, CCTV support brackets, RFID access for advanced security.

- Rapid On-site Installation: Modular design shortens airport fence installation time by up to 40% vs. conventional fencing.

- Wide Compliance: All products meet/overpass ISO 1461, ISO 9227, ANSI/ASTM, EN 10244 norms.

Third-party certifications and rigorous in-factory/non-destructive testing ensure every airport fence delivers guaranteed, long-term perimeter safety.

| Parameter | Unit | Typical Value | Industry Standard |

|---|---|---|---|

| Panel Height | mm | 2400 / 2700 / 3000 | ≥2400 |

| Panel Width | mm | 2500 / 3000 | 2000–3000 |

| Mesh Size | mm | 50x100 / 75x150 | ≤75x150 |

| Wire Diameter | mm | 4.0–6.0 | ≥4.0 |

| Galvanization Layer | g/m² | ≥270 | ≥275 |

| PVC/PE Coating | μm | 80–130 | ≥100 |

| Salt Spray Endurance | h | 1000+ | ≥720 |

| Criteria | DQFence (airport fence) | Generic Supplier |

|---|---|---|

| Experience | 15+ Years, 90+ Countries Served | 3–8 Years |

| Certification | ISO 9001:2015, CE, SGS, CNAS | Partially ISO |

| Customization | 100% OEM, RAL Color/Shape | Limited |

| Logistics | Global Fast Shipping | Domestic Only |

| Compliance | ICAO, ASTM, ANSI | Basic |

| After-sales | 7×24h, Dedicated Team | Worktime Only |

DQFence partners with leading airports in Europe, Southeast Asia, and Africa, is recognized by government procurement authorities, and frequently participates in industry standardization panels.

- Design Proposal: Engineers propose custom airport fence solutions (3D CAD drawing, wind-resistance, anti-intrusion level calculations).

- Technical Support: Pre-installation site survey, compliance consulting, technical documentation in line with local regulations.

- Bidding Support: Complete technical submittals, samples, and past project datasheets for bidding/tender process.

- Material Branding: Embossed logos, serialized tagging, or RFID-enabled asset management optional.

- Turnkey Installation: Installation training, on-site support, multilingual assembly guides.

- Smart Security: Integration with perimeter sensors (vibro-cable, LIDAR, thermal imaging), real-time alerts.

- Specification: 3.0m H, 4.5mm wire, Y-top, double razor wire, anti-rust epoxy powder coat, 8km length.

- Performance: Zero theft/intrusion events in 24 months, reduced maintenance cost by 65% versus old fence.

- Client feedback: "DQFence's airport fence system delivered reliability and peace of mind. Post-sale support has been exceptional."

- Extremely high salt, heat, and dust resistance (tested at 1000+ hours per ISO 9227).

- Custom color scheme, integrated access smart gate, and branded panels.

- Coated 304 stainless mesh ensures no corrosion after 18 months in operation.

- Smart fence integration—vibration sensors and fiber cables for 24/7 intrusion detection.

- Lead Time: 18–25 days (bulk), customs documentation, and worldwide shipping.

- Warranty: 5 years on materials, 2 years on accessories.

- Quality: Every airport fence batch inspected per ISO 9001:2015, with SGS/CE certificates attached to shipment.

- Customer Support: Dedicated support team, bilingual technical consultants, cloud-based project tracking.

- Free samples & BIM/CAD drawings provided for approved projects/bids.

The evolution of airport fence technology is driving rapid upgrades in global perimeter and aviation security. Through continuous innovation in materials science, anti-intrusion design, and smart system integration, top-tier solutions such as those from DQFence are now safeguarding critical infrastructure worldwide.

Further reading:

[1] “Best Practices for Airport Perimeter Security” (ACI Official Guide)

[2] “Perimeter Intrusion Detection for Airports” (SecurityInfoWatch Industry Analysis)

[3] “Airport Security Fencing Standards and Innovations, 2024” (IFSEC Global)

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025