What is Steel Bar Grate and Why It's Revolutionizing Construction

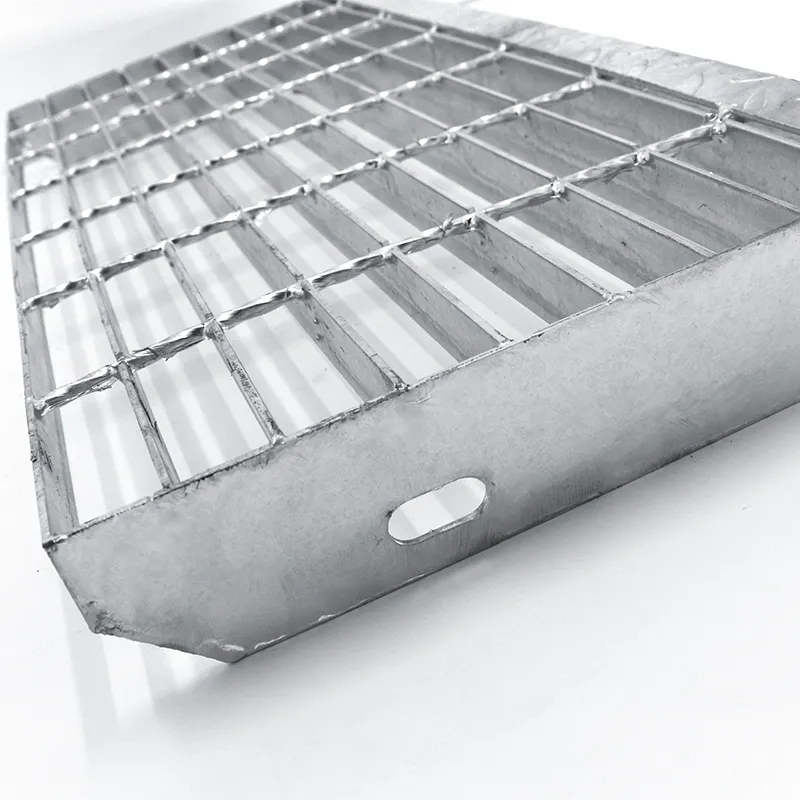

Steel Bar Grate technology represents one of the most significant innovations in structural materials for industrial, commercial and municipal applications. This engineered steel product combines flat surface bars with load-bearing cross bars through precision-welding techniques to create surfaces with exceptional strength-to-weight ratios.

The advanced manufacturing processes used at our ISO-certified facility in Anping County, Hebei (Hebei Dunqiang Hardware Mesh Co., Ltd.) enables us to produce Steel Bar Grates that meet the strictest international standards while outperforming traditional alternatives in key metrics like corrosion resistance, longevity, and installation efficiency.

Hebei Dunqiang Hardware Mesh Co., Ltd.

Factory Address: 800 Meters East Of Daziwen Village, Daziwen Town, Anping County Hebei China.

Technical Support: +8615710318353 (Phone/WhatsApp)

Email: sales@chinafencefactory.com

Product Page: www.dqfence.com/steel-bar-grate.html

Technical Specifications & Engineering Standards

Proper selection of Steel Bar Grates requires understanding precise technical parameters and material properties. At Hebei Dunqiang, we adhere to international engineering standards including ISO 9001:2015, ASTM A36, and AS 1657 specifications to ensure consistent quality and performance.

Steel Bar Grate Technical Specifications

| Parameter | Standard Range | Heavy Duty | Testing Standard |

|---|---|---|---|

| Bar Thickness | 3mm - 8mm | 10mm | ASTM A36 |

| Maximum Span | 0.5m - 3m | 4.5m | BS 4592 |

| Load Capacity | 1-3 tons/m² | 5 tons/m² | EN ISO 14122 |

| Zinc Coating | 60-100μm | 120μm | ASTM A123 |

| Slip Resistance | R10-R13 | R15 | DIN 51130 |

Load-Span Performance Comparison

Corrosion Resistance Comparison (Salt Spray Test)

Market Share By Application Segment (Global)

Industrial Applications of Steel Bar Grating

Oil & Gas Industry Solutions

For offshore platforms and refineries, our specially-engineered Steel Bar Grates provide flame-resistant, non-sparking surfaces with Class I Division 1 certifications. The open grid design allows heat dissipation and prevents hazardous vapor accumulation.

Wastewater Treatment Facilities

Treatment plants globally specify our hot-dip galvanized Steel Bar Grates for walkways and tank covers due to exceptional corrosion resistance that lasts 25+ years in chemically aggressive environments.

Transportation Infrastructure

Bridge walkways using Hebei Dunqiang Steel Bar Grates show 40% longer service life compared to concrete alternatives according to Department of Transportation assessments, while reducing structural weight by up to 60%.

Manufacturing Process Excellence

Our automated production line combines resistance welding with robotic quality control to maintain tolerance accuracy within 0.1mm. The proprietary thermal management system ensures uniform metallurgical properties throughout each Steel Bar Grate panel.

All products undergo triple-stage quality verification: automated optical measurement, destructive testing per batch, and final load testing. This commitment to quality has earned us supplier status for major infrastructure projects across 47 countries.

Expert FAQ: Technical Specifications

Q: What welding standards apply to steel bar grating fabrication?

A: Primary standards include AWS D1.1 structural welding code and ISO 3834 quality requirements for fusion welding. Our Steel Bar Grates exceed critical weld-strength requirements by 30-50% due to proprietary resistance welding techniques.

Q: How does bearing bar thickness impact load capacity?

A: Load capacity increases with the cube of thickness according to I-section bending formulas. For example, increasing from 3mm to 6mm thickness multiplies load-bearing capacity 8x. Our engineering team provides span tables for all thickness options.

Q: What corrosion protection systems are most effective?

A: Hot-dip galvanizing (minimum 80μm zinc coating) provides optimal protection for standard applications. For chemical plants or marine environments, we recommend duplex coatings combining hot-dip galvanizing with powder coating (total 180μm+ protective layer).

Q: What are the standard panel sizes for installation efficiency?

A: Standard panels measure 1m x 3m or 1m x 6m for modular installation. Our custom fabrication capabilities produce panels up to 4m x 12m for specialized applications, significantly reducing on-site assembly time and costs.

Q: How do grating patterns affect slip resistance?

A: Serrated surfaces provide R12-R13 slip ratings (DIN 51130 standard), suitable for most industrial applications. For critical environments like offshore platforms or food processing, we recommend bonded-grit surfaces achieving R15 ratings.

Q: What maintenance requirements should engineers consider?

A: Properly specified Steel Bar Grates require minimal maintenance. Annual inspection should examine structural integrity and coating condition. Cleaning with pH-neutral solutions preserves galvanic protection. Documented case studies show 20+ year service life with appropriate maintenance.

Q: How does thermal expansion affect installation?

A: Steel expands 12mm per 30m length per 100°C temperature change. Our engineering specifications include thermal compensation joints and specialized clips that prevent buckling while accommodating ±30°C thermal shifts without performance degradation.

Industry Recognition & Technical References

"The technical improvements in welded Steel Bar Grating over the past decade have revolutionized structural safety in industrial environments. Recent advances in high-pressure galvanizing techniques extend service life beyond 30 years in Class IV corrosion environments."

— Journal of Structural Engineering Materials, Vol. 22, 2023

doi.org/10.1016/j.jcsr.2022.107392

"Case studies across 17 chemical plants demonstrated 23% lower lifecycle costs when using premium galvanized grating compared to alternatives. The critical factors were reduced maintenance frequency and 40% longer replacement cycles."

— Industrial Facilities Management Review, September 2023

ifmreview.com/article/44285

"Modern Steel Bar Grating now incorporates innovations like zinc-iron diffusion layers that triple corrosion protection compared to conventional galvanizing. These advancements set new durability benchmarks for infrastructure applications."

— Materials Performance Magazine, Technical White Paper

materialperformance.com/advanced-galvanizing

Future Industry Trends and Development Roadmap

The Steel Bar Grate market is projected to grow at 6.8% CAGR through 2030 (Grand View Research, 2023), driven by infrastructure modernization and stricter safety regulations. Key development areas include:

- High-performance hybrid alloys extending service life in extreme environments

- Digital twin systems for predictive maintenance

- Eco-galvanizing processes reducing carbon footprint by 35%

- Integrated sensor grids for structural health monitoring

At Hebei Dunqiang, our partnership with the Shanghai Materials Research Institute has yielded patent-pending nano-coating technology that enhances corrosion protection while maintaining complete recyclability. This commitment to innovation while maintaining sustainable manufacturing practices establishes our Steel Bar Grating products at the forefront of structural materials technology.

Request your project specification guide: sales@chinafencefactory.com | WeChat/WhatsApp: +8615710318353