- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Aug . 17, 2025 03:20 Back to list

Durable Crowd Control Barrier Types | Stanchions & Barricades

Understanding Diverse crowd control barrier types and Their Strategic Deployment

Effective crowd management is a critical facet of event planning, public safety, and infrastructure protection, necessitating the strategic deployment of robust and versatile barriers. The market offers a comprehensive range of crowd control barrier types, each designed to meet specific operational requirements, from guiding pedestrian traffic to establishing secure perimeters. Understanding the nuances of these barrier systems, including their material composition, structural integrity, and interlocking mechanisms, is paramount for B2B buyers seeking optimal solutions for large-scale gatherings, construction sites, or public access control. This in-depth analysis delves into the technical specifications, manufacturing processes, and diverse applications of these essential safety components. We explore the latest industry trends influencing barrier design, such as enhanced portability, modularity, and compliance with stringent international safety standards. Furthermore, we provide insights into how advancements in material science and fabrication techniques contribute to the extended lifespan and superior performance of modern crowd barriers, ensuring they withstand harsh environmental conditions and intense usage. Our focus extends to a detailed examination of the inherent advantages different barrier configurations offer, including their ease of assembly, dismantle-ability, and reusability, which collectively drive down operational costs and enhance logistical efficiency for organizations prioritizing both safety and sustainability.

The selection of appropriate crowd control barrier types is not merely about physical separation; it encompasses a complex evaluation of anticipated crowd density, potential security threats, and the specific dynamics of the environment in which they will be deployed. For instance, temporary event barricades differ significantly from permanent security installations, both in design and material choice. Key considerations for B2B procurement professionals include the barrier's resistance to tipping, its ability to withstand lateral pressure from crowds, and its compatibility with various ground surfaces. The integration of advanced interlocking systems, for example, is crucial for creating continuous, impenetrable lines, preventing unauthorized access or accidental breaches. Moreover, the evolving landscape of public safety demands barriers that can be rapidly deployed and reconfigured to adapt to changing crowd flow patterns or emergency situations. This adaptability is particularly vital in dynamic environments like music festivals, sporting events, and large-scale public demonstrations, where unforeseen circumstances can arise. We will also touch upon the economic benefits of investing in high-quality, durable crowd control barricades for sale, highlighting how their longevity and minimal maintenance requirements translate into a lower total cost of ownership over their operational lifespan.

Advanced Manufacturing Processes for Superior Crowd Control Barriers

The reliability and performance of crowd control barrier types are direct reflections of their manufacturing processes, which demand precision engineering and high-quality materials. Typically, these barriers are constructed from robust materials such as galvanized steel, aluminum, or high-density polyethylene (HDPE), chosen for their durability, corrosion resistance, and strength-to-weight ratio. The manufacturing journey for a high-grade crowd control barrier commences with the selection of raw materials, followed by cutting and shaping processes using advanced CNC machinery to ensure dimensional accuracy. For steel barriers, the key steps often include welding individual components – such as frames, infill bars, and feet – to form a rigid structure. Post-welding, a crucial stage is surface treatment, which significantly impacts the product's lifespan and resistance to environmental degradation. Hot-dip galvanization, a process where steel is immersed in molten zinc, provides a thick, metallurgically bonded coating that offers superior corrosion protection compared to conventional painting. Alternatively, powder coating, an electrostatic application of dry powder that is then cured under heat, creates a hard finish tougher than traditional paint. These surface treatments are critical for barriers deployed in diverse environments, from humid coastal regions to industrial zones where chemical exposure is a concern.

Following surface treatment, the assembly of modular components and the integration of specialized features like interlocking hooks or anti-trip feet are performed. Quality control is meticulously enforced at every stage, from raw material inspection to final product verification. This includes non-destructive testing (NDT) methods like ultrasonic testing for weld integrity and material thickness measurements. Performance testing, simulating real-world conditions, is also conducted to assess stability, load-bearing capacity, and resistance to impact. Compliance with international standards such as ISO 9001 for quality management and ANSI standards for safety and performance is non-negotiable for reputable manufacturers. A well-manufactured crowd control barrier is expected to have a service life exceeding 15-20 years, even under demanding conditions, thanks to these rigorous processes. Such longevity makes them ideal for a broad spectrum of industries, including petrochemical plants requiring secure perimeters, metallurgical facilities needing robust safety zones, and municipal water supply and drainage projects where public access must be restricted. The superior design and manufacturing lead to significant advantages in typical application scenarios, such as reduced maintenance costs due to enhanced anti-corrosion properties and improved safety due to greater structural stability, indirectly contributing to energy efficiency by preventing costly downtime and resource reallocation.

Technical Specifications and Performance Metrics

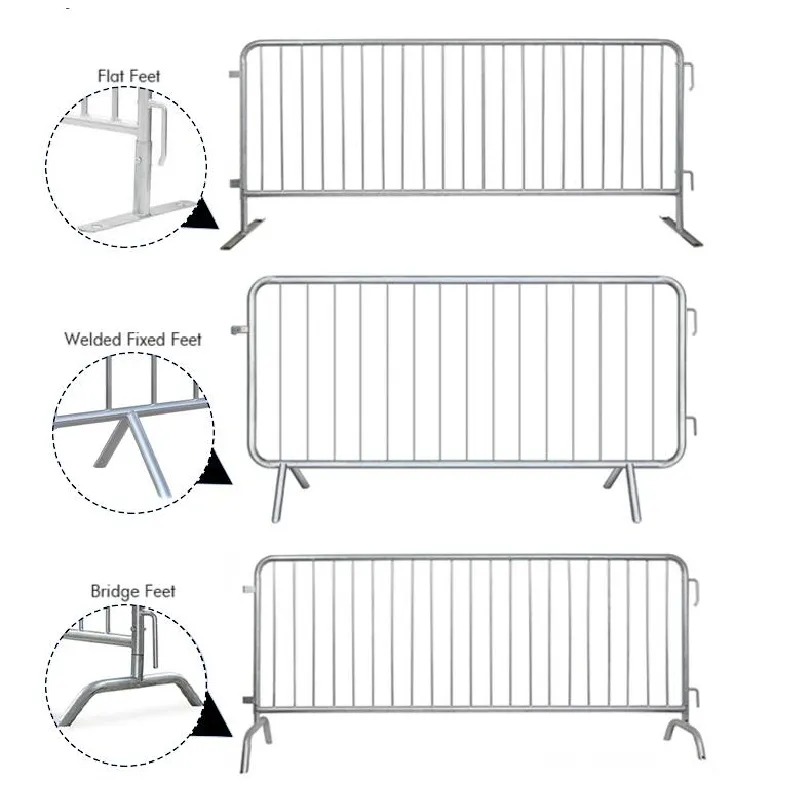

The performance of various crowd control barrier types is quantifiable through a series of technical parameters that guide procurement decisions. These specifications often include dimensions (length, height, width), weight, material grade (e.g., Q235 steel, T6061 aluminum, HDPE), and surface finish. For instance, standard steel pedestrian barriers typically measure around 2.3 to 2.5 meters in length and 1.1 meters in height, with frame pipe diameters ranging from 38mm to 48mm and infill picket diameters of 16mm to 20mm. The choice of feet – flat, bridge, or fixed – impacts stability and stackability. Bridge feet offer excellent stability on uneven terrain, while flat feet minimize tripping hazards and facilitate stacking. Load-bearing capacity, often measured in kN (kilonewtons) per linear meter, is a critical metric for assessing a barrier's ability to withstand crowd pressure. Durability, encompassing resistance to impact, abrasion, and UV radiation, is also a key factor, particularly for long-term outdoor deployments. The interlocking system, whether hook-and-loop, pin-and-hole, or a proprietary design, dictates the ease of assembly and the integrity of the barrier line. Advanced designs minimize gaps between units, preventing unauthorized passage.

Environmental resistance is another crucial technical parameter. Barriers designed for corrosive environments, such as those near coastal areas or industrial plants, will feature enhanced anti-corrosion treatments beyond standard galvanization, possibly involving specialized polymer coatings or marine-grade alloys. Temperature resistance is also vital, ensuring structural integrity in extreme hot or cold climates. For high-security applications, parameters like anti-climb features, typically achieved through closely spaced vertical infill bars or anti-climb mesh, become paramount. The ease of transportation and storage, often indicated by stackability ratios and compatibility with standard pallet sizes, directly influences logistics and operational costs for organizations requiring efficient deployment and recovery. When considering crowd control stanchions wholesale, these technical details become the cornerstone of value assessment, ensuring that the bulk purchase aligns with specific operational demands and long-term asset management strategies. Prospective buyers should always request detailed specification sheets and, where possible, independent test reports to verify claimed performance metrics, ensuring full compliance with project-specific safety and operational guidelines.

Key Technical Parameters of Common Crowd Control Barrier Types

| Parameter | Steel Pedestrian Barrier | Aluminum Crowd Barrier | HDPE Barrier |

|---|---|---|---|

| Material | Q235 Hot-Dip Galvanized Steel | 6061-T6 Aluminum Alloy | High-Density Polyethylene |

| Standard Dimensions (L x H) | 2.5m x 1.1m | 1m x 1.2m (Front stage) | 2m x 1m |

| Frame Pipe Diameter | 38mm - 48mm | 50mm - 60mm | Varies (Solid Mold) |

| Infill Picket Diameter | 16mm - 20mm | Not applicable (Panel design) | Not applicable (Solid Panel) |

| Weight (Approx.) | 15-20 kg/unit | 25-35 kg/unit | 10-15 kg/unit |

| Surface Finish | Hot-Dip Galvanized, Powder Coated | Anodized, Powder Coated | UV Stabilized Colors |

| Interlocking Mechanism | Hook & Loop | Pin & Hole, Gravity Lock | Male/Female Connectors |

| Typical Lifespan | 15-20+ years | 20-25+ years | 10-15 years |

Application Scenarios and Strategic Advantages

The versatility of various crowd control barrier types enables their deployment across a wide array of sectors and environments, each benefiting from specific design features. In the event management industry, from major concerts and sporting events to public festivals, portable steel barriers with their robust construction and ease of deployment are indispensable for creating pedestrian walkways, segmenting VIP areas, and managing ingress/egress points. Their strength makes them ideal for withstanding surges from large crowds. For more intimate or aesthetic settings, such as corporate events or art exhibitions, a more refined crowd control barrier might be preferred, often featuring sleek designs or branded panels that integrate seamlessly with the event's visual theme. In urban construction zones, heavy-duty steel barriers or water-filled plastic barriers serve to secure hazardous areas, protect workers, and guide traffic flow, providing a clear demarcation between active work sites and public access routes. The durability and high visibility of these barriers are crucial for enhancing safety and preventing accidental intrusion.

Beyond events and construction, crowd barriers find critical applications in emergency management, public safety, and infrastructure protection. During natural disasters or public emergencies, they can be rapidly deployed to establish exclusion zones, manage evacuation routes, and control access for first responders. In sensitive areas like airports, government buildings, or industrial facilities, high-security barrier solutions, including anti-climb and vehicle-rated options, are used to reinforce perimeter security and mitigate potential threats. These barriers often integrate with existing security systems and are designed to withstand significant impact. The strategic advantages of investing in high-quality crowd control barricades for sale include enhanced public safety, optimized logistical efficiency, and improved operational control. By effectively channeling pedestrian and vehicular traffic, these barriers reduce the risk of accidents, stampedes, and unauthorized access, thereby safeguarding both individuals and assets. Furthermore, their reusability and minimal maintenance requirements translate into significant long-term cost savings, offering an excellent return on investment for organizations prioritizing both security and fiscal prudence. The ability to quickly adapt layouts further reduces operational costs during events by minimizing setup and teardown times.

Choosing the Right Supplier: Manufacturer Comparison and Customization

Selecting the ideal manufacturer for crowd control barrier types requires a diligent evaluation process that extends beyond mere product specifications to encompass reputation, service, and the ability to deliver bespoke solutions. A reputable supplier, like DQ Fence, will demonstrate not only adherence to ISO 9001 quality management systems but also possess decades of experience in the industry, having served a diverse clientele ranging from small event organizers to large-scale infrastructure projects. Key differentiators include the consistency of material quality, the precision of manufacturing processes, and the robustness of the finishing treatments. For instance, comparing the thickness and evenness of galvanization, or the adhesion and durability of powder coatings, can reveal significant disparities in product longevity. Manufacturers who invest in advanced automation and rigorous quality control protocols typically produce superior barriers that offer greater resilience and a longer operational lifespan, minimizing the need for frequent replacements and maintenance. Furthermore, the ability of a manufacturer to provide comprehensive technical support, including site surveys and deployment recommendations, adds substantial value to the procurement process.

Customization options are increasingly vital for B2B clients seeking solutions tailored to their unique brand identity or specific operational challenges. Leading manufacturers offer a spectrum of customization capabilities for crowd barriers, including custom dimensions, specialized finishes, corporate branding (e.g., logos, specific color schemes), and integration with other security or signage elements. For example, a client requiring barriers for a high-profile sporting event might request specific team colors, integrated advertising panels, or unique interlocking mechanisms for enhanced security. For crowd control stanchions wholesale, the ability to order large volumes with consistent quality and competitive pricing, coupled with flexible delivery schedules, is paramount. Reputable suppliers provide clear lead times, often around 15-30 days for standard orders and slightly longer for customized solutions, ensuring projects stay on schedule. They also offer robust warranty policies, typically covering manufacturing defects for 5-10 years, reflecting their confidence in product durability. An excellent manufacturer will also provide dedicated account management and after-sales support, guaranteeing a seamless experience from initial consultation to post-installation service, which builds trust and fosters long-term partnerships.

Comparative Analysis: Standard vs. Premium Crowd Barriers

| Feature | Standard Barrier (e.g., Entry-Level Steel) | Premium Barrier (e.g., Heavy-Duty Galvanized Steel) |

|---|---|---|

| Material Quality | Commercial grade steel, lighter gauge | High-grade Q235/Q345 steel, thicker gauge |

| Corrosion Protection | Pre-galvanized or painted | Hot-dip galvanized (80+ microns) + optional powder coat |

| Weld Quality | Basic industrial welds | Precision robotic/manual welds, full penetration |

| Feet Design | Simple fixed feet, potential tripping hazard | Flat feet or removable bridge feet, optimized stability & safety |

| Interlocking Mechanism | Basic hook/loop, may have play | Robust, anti-tamper, tight-fitting connections |

| Lifespan (Est.) | 5-10 years | 15-25+ years |

| Load Bearing Capacity | Standard, sufficient for light crowd control | High, tested for dense crowds and impact resistance |

| Price Point | Lower initial investment | Higher initial investment, lower TCO |

Real-World Impact: Application Cases and Testimonials

The tangible benefits of deploying high-quality crowd control barrier types are best illustrated through real-world application cases and client testimonials, which underscore their practical effectiveness and long-term value. One notable instance involves a major international marathon in a metropolitan area. Faced with the challenge of managing hundreds of thousands of spectators along a 42-kilometer route, event organizers utilized thousands of galvanized steel pedestrian barriers. These barriers, chosen for their robust construction and effective interlocking system, successfully created secure viewing corridors, prevented spectator encroachment onto the race path, and facilitated smooth access for emergency services. The ease of deployment and subsequent dismantling, coupled with their stackability for efficient storage, significantly reduced logistical complexities and labor costs for the event management team. The project manager noted, "The durability and rapid deployment of these crowd barriers were instrumental in ensuring the safety of both participants and spectators, allowing us to focus on the event itself."

Another compelling case study involves a large-scale infrastructure project that required securing a multi-acre construction site adjacent to a bustling public park. Here, the use of heavy-duty, anti-climb crowd control barricades for sale, enhanced with specialized base plates for added stability on uneven ground, proved critical. These barriers not only deterred unauthorized entry but also protected the public from construction hazards, such as falling debris and heavy machinery operations. The robust hot-dip galvanization ensured the barriers withstood harsh weather conditions and corrosive elements typical of construction environments for years without degradation. A spokesperson for the construction firm stated, "Our commitment to safety is paramount, and these barriers have been a cornerstone of our site security strategy. Their resilience and minimal maintenance have provided immense value, proving to be a cost-effective solution over the project's multi-year timeline." These examples highlight how the right crowd control barrier types, supported by expert consultation and reliable product delivery, can provide measurable improvements in safety, efficiency, and operational success across diverse industries.

Ensuring Trust: FAQs, Delivery, Warranty, and Support

Building trust with B2B clients, particularly when sourcing essential safety equipment like crowd control barrier types, necessitates transparency in all aspects of procurement and after-sales service. A comprehensive FAQ section can proactively address common inquiries regarding product specifications, customization options, and installation procedures, providing immediate clarity for potential buyers. For example, frequently asked questions might include: "What is the typical lead time for large orders?" (Answer: Generally 15-30 working days, depending on quantity and customization, with expedited options available), or "Are your barriers compatible with other manufacturers' systems?" (Answer: While designed for seamless integration within our own product lines, we offer custom connectors for interoperability with specific existing systems upon request). Clarity on delivery logistics is also paramount. Reputable manufacturers provide detailed information on shipping methods, packaging standards to prevent damage during transit, and estimated delivery schedules, ensuring that crowd control stanchions wholesale orders arrive on time and in perfect condition, minimizing disruptions to client projects. This meticulous approach to logistics is a hallmark of a customer-centric supplier.

Beyond initial purchase and delivery, robust warranty policies and responsive customer support are critical for fostering long-term client relationships. A credible manufacturer will offer a comprehensive warranty, typically ranging from 5 to 10 years, covering manufacturing defects and material integrity under normal usage conditions. This commitment reflects confidence in the product's quality and provides peace of mind for buyers. Prompt and knowledgeable customer support, available through multiple channels such as phone, email, or dedicated online portals, ensures that any post-purchase queries, technical issues, or maintenance requirements are addressed efficiently. Furthermore, ongoing technical assistance, including advice on proper storage, maintenance, and repair, extends the product's lifespan and maximizes the return on investment for clients. Our commitment to excellence is reflected not only in the superior quality of our crowd barriers but also in our unwavering dedication to client satisfaction, ensuring that every interaction, from initial inquiry to long-term operational support, is characterized by professionalism, reliability, and unparalleled expertise.

Frequently Asked Questions (FAQs)

-

Q: What is the typical lead time for a bulk order of crowd barriers?

A: For standard crowd control barrier types, lead times typically range from 15 to 30 working days for production and preparation for shipment, depending on the order volume and current factory capacity. Customized orders may require slightly longer. -

Q: What kind of warranty do you offer on your crowd barriers?

A: We provide a comprehensive 5 to 10-year warranty on our crowd control barrier products, covering manufacturing defects and ensuring material integrity under normal operating conditions. -

Q: Can your barriers be customized with specific colors or branding?

A: Absolutely. We offer extensive customization options for crowd barriers, including specific RAL colors, powder coating finishes, integration of company logos, and custom dimensions to meet your precise project requirements. -

Q: How do your barriers handle extreme weather conditions?

A: Our crowd control barrier types are engineered with advanced corrosion protection, such as hot-dip galvanization and UV-resistant powder coatings, ensuring optimal performance and longevity in diverse environmental conditions, from harsh sunlight to heavy rain and extreme temperatures.

Authoritative References and Industry Standards

- International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems – Requirements.

- American National Standards Institute (ANSI). ANSI Z245.1-2017: Waste and Recyclable Materials Handling Equipment – Mobile & Stationary Compactors – Safety Requirements. (Referenced for general safety compliance framework)

- ASTM International. ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- National Fire Protection Association (NFPA). NFPA 101: Life Safety Code. (Referenced for crowd flow and safety principles)

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025