- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Aug . 14, 2025 03:20 Back to list

Crowd Control Barrier Types: Stanchions, Barricades & More!

The Imperative of Crowd Management: Exploring crowd control barrier types

Effective crowd management is paramount in ensuring safety, order, and operational efficiency across a myriad of sectors. From bustling public events and construction zones to industrial sites and emergency response areas, the controlled movement and segregation of people are critical. This article delves into the diverse crowd control barrier types available, their technical specifications, manufacturing intricacies, and strategic applications. We aim to provide B2B decision-makers and technical personnel with a comprehensive understanding of these essential tools, highlighting their role in enhancing security, streamlining operations, and mitigating risks. The global market for physical security equipment, including crowd control solutions, continues to expand, driven by increasing public safety concerns and the demand for robust, deployable infrastructure.

Understanding the nuances of each barrier type, from material composition to interlocking mechanisms, is vital for selecting the optimal solution for specific environmental demands. We will also explore the prevailing industry trends that influence barrier design and deployment, such as modularity, rapid deployment capabilities, and enhanced durability. Our focus remains on equipping you with the knowledge to make informed procurement decisions, ensuring your investment aligns with the highest standards of safety, efficiency, and longevity. The emphasis on engineering precision and adherence to international standards distinguishes superior crowd control barrier types in a competitive market.

Deconstructing Different Crowd Control Barrier Types and Their Applications

The array of crowd control barrier types is designed to meet varied operational requirements, each offering distinct advantages in specific scenarios. Common types include:

- Steel Barricades (Pedestrian Barriers): These are perhaps the most ubiquitous, constructed from galvanized steel for maximum durability and corrosion resistance. Featuring interlocking systems, they form continuous, robust lines ideal for perimeter control, queue management, and directing foot traffic at large events, construction sites, and public gatherings. Their inherent strength provides a high level of security.

- Water-Filled Barriers (Plastic Barricades): Made from high-density polyethylene (HDPE), these barriers are lightweight when empty, facilitating easy transport and deployment. Once filled with water or sand, they become substantial and stable, offering a significant deterrent. They are often used for temporary road closures, construction zones, and delineation of sensitive areas. Their bright colors (often red or orange) enhance visibility.

- Event Barriers (Concert Barriers/Bike Rack Barriers): Specifically designed for high-stress environments like concerts and rallies, these heavy-duty barriers feature wider bases and anti-climb designs. They are engineered to withstand significant pressure from large crowds, ensuring performer and public safety. Their modularity allows for flexible configurations.

- Retractable Belt Barriers (Stanchions): Commonly seen in airports, banks, and retail environments, these are primarily for queue management and creating temporary pathways. They consist of a post with a retractable belt, offering flexibility and ease of re-configuration for light-duty crowd direction. Providers often offer crowd control stanchions wholesale for bulk procurement.

- Vehicle Barriers (K-Rails/Jersey Barriers): While heavier and more permanent, these are crucial for vehicle control and critical infrastructure protection. They can be made from concrete or water-filled plastic, designed to redirect or stop vehicles. They are integral to security planning in high-risk zones.

The selection of the appropriate barrier type hinges on factors such as anticipated crowd density, duration of deployment, environmental conditions, and the specific security objectives. Each type serves a unique purpose in the comprehensive strategy of crowd management and security.

Manufacturing Precision: The Crafting of Durable Crowd Control Barriers

The production of high-quality crowd control barricades for sale involves a rigorous multi-stage manufacturing process, ensuring durability, functionality, and compliance with international safety standards. For steel barriers, the primary material is typically high-grade galvanized steel, renowned for its strength-to-weight ratio and inherent resistance to corrosion. The typical manufacturing flow includes:

- Material Procurement & Inspection: Sourcing high-tensile steel tubing and sheet metal, followed by rigorous quality checks to ensure compliance with material specifications (e.g., ASTM A500 for structural tubing).

- Cutting & Forming: Precision cutting of steel components using automated CNC laser or plasma cutters ensures accurate dimensions. Bending and forming processes, often utilizing hydraulic press brakes, shape the steel into frames, vertical uprights, and interlocking hooks/loops.

- Welding: Components are then meticulously welded together using advanced MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding techniques. This ensures strong, durable joints capable of withstanding significant lateral forces and repeated use. All welds undergo visual and sometimes ultrasonic inspection.

- Surface Treatment (Galvanization): This is a critical step for steel barriers. Hot-dip galvanization, conforming to standards like ISO 1461 or ASTM A123, applies a protective zinc coating. This sacrificial layer provides superior corrosion resistance, significantly extending the barrier's service life, especially in harsh outdoor environments or coastal areas.

- Optional Powder Coating: For enhanced aesthetics and additional corrosion protection, barriers may undergo electrostatic powder coating. This provides a durable, chip-resistant finish in various colors.

- Assembly & Quality Control: Final assembly of components, including feet and interlocking mechanisms. Each barrier undergoes a comprehensive quality inspection, checking dimensions, weld integrity, coating thickness, and functionality of interlocking systems. Compliance with ISO 9001 quality management standards is crucial.

For HDPE barriers, the process involves rotational molding or blow molding of UV-stabilized virgin polyethylene, ensuring colorfastness and resistance to environmental degradation. Strict adherence to ISO and ANSI standards across all manufacturing stages guarantees a product with an extended service life, typically exceeding 10-15 years for galvanized steel barriers even in challenging industrial sectors like petrochemical facilities, metallurgy plants, or municipal water supply and drainage projects, where anti-corrosion properties are paramount. This meticulous process ensures the longevity and reliability of all crowd control barrier types.

Technical Parameters & Performance Metrics of Crowd Control Barrier Types

The performance and suitability of crowd barriers are directly tied to their technical specifications. Below is a comparative table outlining common parameters for typical crowd control barrier types, providing insights into their structural integrity and operational characteristics. These metrics are crucial for engineers and procurement specialists to assess compliance and functional efficacy.

| Parameter | Steel Pedestrian Barrier | Water-Filled HDPE Barrier | Heavy-Duty Event Barrier |

|---|---|---|---|

| Material | Hot-Dip Galvanized Steel (Q235) | UV-Stabilized High-Density Polyethylene (HDPE) | Heavy Gauge Steel (Q345) |

| Standard Dimensions (L x H) | 2.5m x 1.1m (8.2ft x 3.6ft) | 2.0m x 1.0m (6.6ft x 3.3ft) | 2.0m x 1.2m (6.6ft x 3.9ft) |

| Frame Pipe Diameter | 38mm - 42mm (1.5" - 1.65") | N/A (Molded Structure) | 48mm - 60mm (1.9" - 2.36") |

| Infill Picket Diameter | 16mm - 20mm (0.63" - 0.79") | N/A (Solid Body) | 25mm - 32mm (0.98" - 1.26") |

| Weight (Empty/Filled) | 16-22 kg (35-48 lbs) | 10-15 kg (empty) / 200-300 kg (filled) | 30-45 kg (66-99 lbs) |

| Interlocking System | Hook & Loop / Pin & Hole | Male & Female Ends | Heavy-Duty Pin & Receiver |

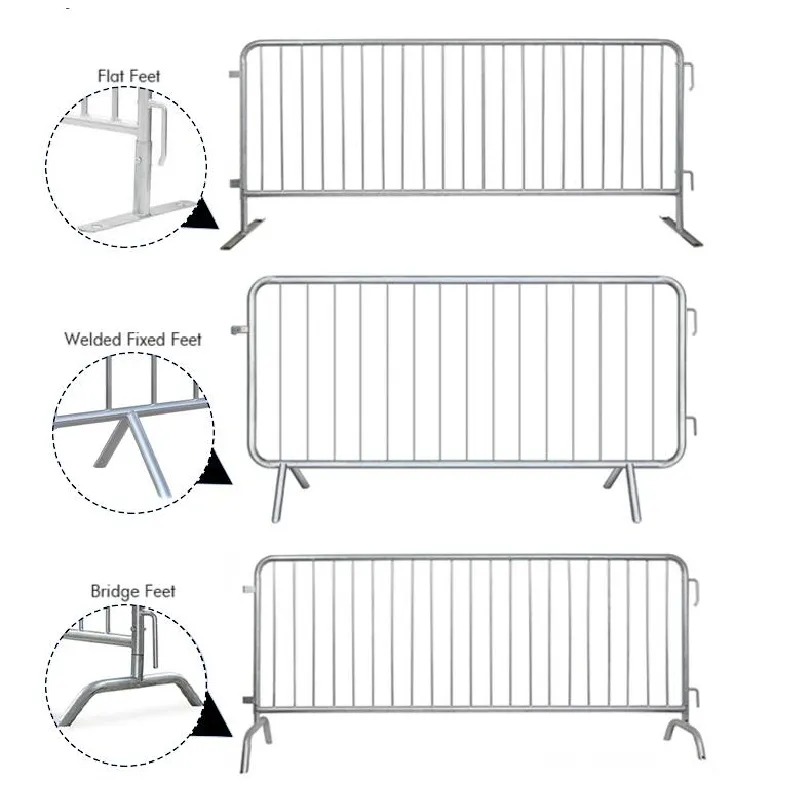

| Foot Type | Flat / Bridge / Detachable | Integrated / Stackable | Heavy-Duty Fixed / Detachable |

| Lifespan (Estimated) | 10-15+ years (Galvanized) | 5-10 years (UV-Protected) | 15-20+ years (Heavy-Duty Galvanized) |

These parameters highlight the engineering design choices made to optimize each barrier type for its intended use, from ease of handling to resistance against environmental stressors and crowd pressure. The longevity and anti-corrosion properties, especially of galvanized steel options, offer significant long-term value and reduce replacement costs, contributing indirectly to operational energy savings by providing a durable, reusable solution. Manufacturers often provide detailed technical data sheets and certifications (e.g., ISO 17025 for testing labs) validating these specifications.

Versatile Applications and Technical Advantages in Diverse Sectors

The versatility of crowd control barrier types makes them indispensable across a broad spectrum of industries, providing critical infrastructure for safety and operational flow. Their technical advantages translate directly into tangible benefits for organizations. For instance, in event management, from concerts and festivals to sporting events, barriers are crucial for establishing perimeters, managing queues, segmenting VIP areas, and ensuring emergency egress routes remain clear. The robust interlocking systems of steel barriers prevent unauthorized dismantling, maintaining crowd order and security.

In the construction industry, crowd control barricades for sale serve to secure dangerous zones, guide pedestrian and vehicle traffic safely around work areas, and delineate site boundaries. Their durability, especially against impacts and harsh weather, ensures long-term reliability on dynamic construction sites. Similarly, in public safety and law enforcement, barriers are deployed for crowd containment during demonstrations, securing high-profile areas, and managing disaster response efforts. The quick deployment capability of lightweight plastic barriers or readily interlocked steel barriers is a significant operational advantage in emergency scenarios.

For critical industrial applications, such as petrochemical refineries, metallurgy plants, or extensive water supply and drainage infrastructure projects, the anti-corrosion properties of galvanized steel barriers are paramount. These environments often expose equipment to corrosive chemicals, high humidity, or extreme temperatures. Barriers used here must maintain structural integrity to define restricted zones, protect hazardous equipment, and ensure worker safety, directly contributing to compliance with OSHA and local safety regulations. The long service life of these specialized barriers contributes to indirect energy savings by reducing the frequency of replacement and associated manufacturing energy consumption. Furthermore, their stability and resistance to tipping, particularly with features like bridge feet or wide bases, enhance overall safety and minimize potential liabilities. This comprehensive utility underscores the essential nature of high-quality crowd barriers.

Optimizing Procurement: Choosing the Right Manufacturer and Custom Solutions

Selecting a reliable manufacturer for crowd control barrier types is as crucial as understanding the products themselves. A reputable manufacturer, such as DQFence, is distinguished not only by their product range but also by their commitment to quality, adherence to international standards, and capacity for customization. When evaluating potential suppliers, consider their experience in the B2B sector, track record of delivering consistent product quality, and their certifications (e.g., ISO 9001 for quality management, ISO 14001 for environmental management). Transparency in material sourcing and manufacturing processes is also key.

A significant advantage offered by leading manufacturers is the provision of customized solutions. While standard crowd control barrier types suffice for many applications, specific projects may require unique modifications. This could include barriers with custom heights or lengths for particular venue requirements, specialized branding and colors for corporate events, or unique foot designs for uneven terrain. For example, a stadium might require barriers integrated with digital signage capabilities, or a critical infrastructure site might need enhanced anti-climb features and additional anchoring points. A manufacturer capable of bespoke design and fabrication can deliver solutions precisely tailored to your operational needs, optimizing efficiency and safety.

Beyond product customization, a strong manufacturer also offers comprehensive logistical support, competitive crowd control stanchions wholesale pricing, and reliable after-sales service. Their ability to manage large-volume orders and ensure timely delivery is paramount for large-scale projects or continuous supply chain needs. Companies like DQFence leverage decades of experience and robust manufacturing capabilities to provide solutions that meet stringent performance criteria and budget requirements. This partnership approach ensures that your crowd control strategy is not just about purchasing barriers, but about implementing a reliable, long-term safety and operational solution.

Real-World Impact: Application Cases and Customer Success

The true testament to the efficacy of crowd control barrier types lies in their successful deployment in real-world scenarios. Consider a large-scale music festival attracting hundreds of thousands of attendees. Here, heavy-duty event barriers are strategically deployed around stages, VIP sections, and entry/exit points to manage crowd flow, prevent surge incidents, and provide emergency access corridors. The interlocking design ensures these barriers form an impenetrable line, crucial for maintaining safety in high-pressure environments. Client feedback consistently highlights the ease of deployment and the robust stability of these barriers as key factors in seamless event execution, significantly reducing the potential for bottlenecks and security breaches.

Another compelling case involves a major municipal infrastructure project, specifically the upgrading of a city's main water supply network. Given the inherent risks associated with deep excavations and heavy machinery, crowd control barricades for sale, particularly galvanized steel and water-filled plastic barriers, were extensively used. The galvanized steel barriers provided long-term perimeter security for exposed pipelines and construction zones, benefiting from their anti-corrosion properties against ground moisture and urban pollutants. Water-filled barriers, with their high visibility, were deployed to safely redirect pedestrian traffic away from active construction areas, especially during temporary street closures. The feedback from the project management team emphasized the barriers' rapid deployment capability and their resilience to adverse weather conditions, ensuring site safety remained uncompromised throughout the multi-year project duration.

Furthermore, in the context of commercial retail, crowd control stanchions wholesale orders have facilitated organized queue management during peak shopping seasons or product launches. Businesses report improved customer experience, reduced waiting times, and enhanced security against shoplifting by creating clear pathways. These success stories underscore the critical role of well-designed and properly deployed crowd control barriers in maintaining public order, enhancing safety, and optimizing operational efficiency across diverse and demanding applications.

Ensuring Trust and Support: FAQs, Delivery, and Warranty

Establishing trust with B2B clients goes beyond product specifications; it encompasses transparent communication, reliable logistics, and unwavering after-sales support. As a professional supplier of crowd control barrier types, we prioritize these aspects to build long-term partnerships. Below are some frequently asked questions (FAQs) and essential information regarding procurement and support:

Frequently Asked Questions (FAQs)

- Q1: What is the typical lead time for a bulk order of crowd barriers?

A1: Standard bulk orders typically have a lead time of 3-4 weeks from order confirmation, depending on the volume and specific barrier type. For customized solutions, this may extend slightly. We provide precise timelines upon quotation. - Q2: Are your barriers compliant with international safety standards?

A2: Absolutely. Our manufacturing processes and products adhere to strict international standards such as ISO 9001 for quality management, and relevant ASTM/ANSI specifications for material strength and design. We can provide compliance certificates upon request. - Q3: Can crowd control barriers be branded or customized?

A3: Yes, we offer extensive customization options, including powder coating in specific colors (based on RAL codes), adding company logos via decals or laser cutting, and modifying dimensions or foot designs to meet unique project requirements. - Q4: What is the expected lifespan of your galvanized steel barriers?

A4: With proper care and maintenance, our hot-dip galvanized steel barriers are designed for a service life of 10-15 years or more, even in challenging outdoor environments, thanks to superior corrosion resistance.

Delivery and Logistics

We manage a robust global supply chain to ensure efficient and timely delivery of crowd control barricades for sale to your specified location. Our logistics team handles all aspects, including packaging, freight forwarding (sea, air, or land), and customs documentation, providing end-to-end support to minimize your administrative burden. Delivery schedules are meticulously planned and communicated, offering full transparency from order placement to arrival.

Quality Assurance and Warranty Commitment

Every crowd control barrier from our facility undergoes stringent quality control checks to ensure it meets our high standards and your specifications. We stand behind the durability and performance of our products with a comprehensive warranty. Typically, our galvanized steel barriers come with a 5-year limited warranty against manufacturing defects and structural integrity issues. Detailed warranty terms are provided with each quotation, underscoring our commitment to product reliability and customer satisfaction. Our dedicated customer support team is available to assist with any queries or concerns post-delivery, ensuring a seamless experience.

Conclusion: Strategic Investment in Crowd Control Infrastructure

The strategic deployment of appropriate crowd control barrier types is an indispensable component of modern safety and operational management across numerous industries. From the meticulous manufacturing processes that ensure durability and anti-corrosion properties to their versatile applications in event management, construction, and critical industrial sites, these barriers are more than just physical dividers—they are fundamental tools for risk mitigation, public safety, and logistical efficiency. Understanding the technical parameters, industry trends, and the value of custom solutions enables B2B decision-makers to make informed investments that yield significant long-term benefits.

By partnering with a reputable manufacturer committed to quality, compliance, and customer support, organizations can secure high-performance crowd control barricades for sale that meet precise requirements. The longevity, ease of deployment, and robust construction of these barriers contribute directly to operational continuity and reduced maintenance costs, indirectly enhancing energy efficiency through their sustainable design and reusability. Ultimately, investing in high-quality crowd barriers is an investment in safety, order, and the seamless execution of any operation involving human traffic and potential hazards.

References

- International Organization for Standardization (ISO) Official Publications.

- American National Standards Institute (ANSI) Standards Documents.

- ASTM International Standards.

- Occupational Safety and Health Administration (OSHA) Guidelines.

- Journal of Safety Research, Elsevier.

- National Fire Protection Association (NFPA) Codes and Standards.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025