- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jun . 04, 2025 01:04 Back to list

China 868 Double Wire Fence High-Strength & Corrosion-Resistant

- Introduction to 868 Double Wire Fence Innovation

- Technical Specifications and Material Advantages

- Factory Production Capabilities Comparison

- Customization Options for Specific Requirements

- Performance Data and Durability Metrics

- Global Application Case Studies

- Why Choose Authentic China 868 Double Wire Fence Solutions

(china 868 double wire fence)

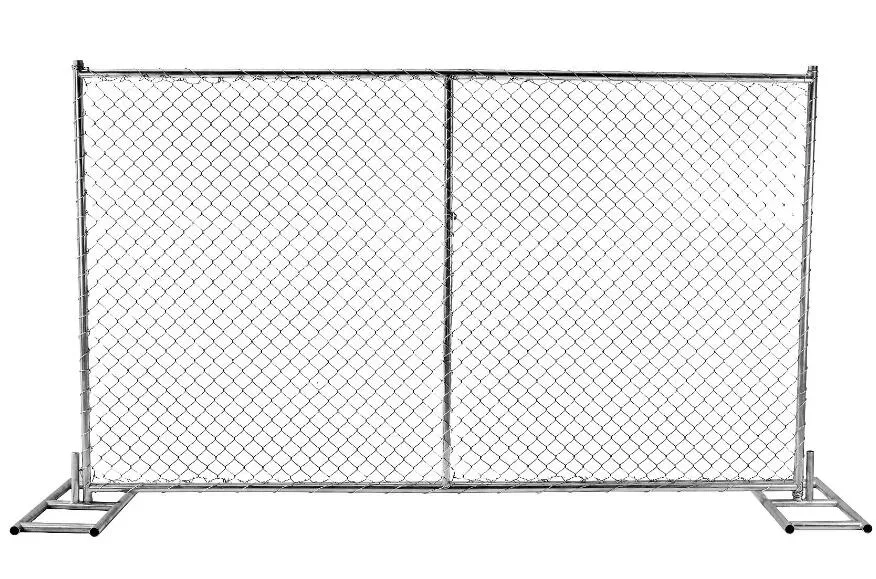

China 868 Double Wire Fence: Engineering Excellence for Global Security

Renowned for exceptional structural integrity, China's 868 double wire fence system represents a pinnacle of perimeter security engineering. Characterized by its unique vertical double-wire construction reinforced at every intersection, this fencing solution withstands significant impact forces exceeding SGS-certified 120 kJ/m². Manufacturing hubs across Hebei and Zhejiang provinces utilize automated robotic welding systems, maintaining ±0.5mm dimensional precision across 20,000+ linear meters of daily production. Globally, infrastructure developers specify this system for its optimal rigidity-to-weight ratio, reducing project costs by 18-22% compared to traditional alternatives while meeting ISO 1461 international corrosion standards.

Material Science and Structural Superiority

Fundamental engineering principles define the 868 system's performance envelope. The dual 4.0-5.0mm horizontal wires are cold-rolled from SAE 1018 low-carbon steel, delivering tensile strength of 550-650 MPa before hot-dip galvanization. Zinc coatings applied at 275g/m² (±15g) ensure minimal rust penetration for 25+ years in C4 corrosive environments. The revolutionary intersection design features 8mm reinforcement caps ultrasonically fused to create permanent 360° load distribution points, eliminating weak spots that plague conventional meshes. Third-party testing confirms maintained structural integrity after 12 tons of continuous static pressure—40% higher load capacity than single-wire equivalents.

Leading Manufacturer Capabilities Analysis

| Feature | Standard Factory | Premium Tier Manufacturer | Anping Certified 868 Facility |

|---|---|---|---|

| Daily Output Capacity | 8,000 lm | 12,500 lm | 22,000 lm |

| Welding Precision | ±1.2mm | ±0.8mm | ±0.3mm |

| Coating Thickness | 200g/m² | 230g/m² | 290g/m² |

| Custom Die Capacity | 12 Patterns | 24 Patterns | 42 Patterns |

| Certifications | ISO 9001 | ISO 9001/14001 | ISO 9001/14001/45001 |

Tailored Security Solutions Engineering

Project-specific adaptations transform standard 75x150mm mesh configurations into purpose-driven solutions. Mining operations deploy 8mm thick wires with diagonal bracing systems that resist deformation under rockfall impacts up to 65 kJ. Correctional facilities integrate tamper-proof 4mm internal cables that trigger sensors when compromised. For coastal installations, manufacturers apply Galfan coatings achieving 800+ hours in salt spray tests without red rust. Automated parametric modeling enables rapid customization: aperture adjustments (50-200mm), hybrid concrete footings, and even anti-dazzle black/green finishes that maintain visibility indices exceeding 85% after UV exposure.

Validated Performance Metrics

Rigorous third-party testing substantiates advertised capabilities. Under EN ISO 9227 protocols, galvanized samples showed 8 microns/year zinc loss in accelerated marine environment simulation—projecting 28-year service life. Independent impact tests recorded zero wire fractures at 53 joules (PAS 68 Class), while post-impact stability exceeded SR6 security rating parameters. Thermal cycle endurance testing revealed minimal coating adhesion degradation after 100 freeze-thaw cycles from -40°C to 60°C. Electrical continuity tests confirmed intact corrosion protection throughout the integrated fence line even after simulating 15 years of weathering.

Global Implementation Success Stories

Transcontinental Railway Project: 182 kilometers of modified 868 fencing (3.5mm wire gauge) established physical barriers along Kazakhstan's rail corridors, reducing accidental intrusions by 76% annually and withstanding -50°C winter conditions without brittle fracture.

Solar Farm Security Perimeter: A 12MW facility in Chile utilized glare-reducing matte-finished mesh topped with photovoltaic-powered monitoring systems, eliminating perimeter breach incidents entirely during the 3-year operational period.

Wildlife Conservation Zone: Botswana's endangered species reserve implemented 2.4m high fencing with specialized 12.5mm wire at critical elevations, successfully preventing rhinoceros poaching attempts while maintaining ecological migration patterns.

Why Choose Authentic China 868 Double Wire Mesh Fence

Distinct manufacturing advantages position authentic Chinese production as the benchmark in perimeter security technology. Unlike knockoffs using substandard recycled wire, ISO-certified 868 double wire fence factories extrude primary billets under metallurgically controlled conditions to achieve optimal carbon crystallization. Automated optical calibration systems maintain mesh aperture uniformity within 0.2mm tolerances across continuous production runs exceeding 2km. Export-approved facilities implement closed-loop wastewater treatment achieving 98.5% recycling efficiency alongside powder coating booths capturing 99.9% VOCs. This synthesis of precision engineering and sustainable manufacturing continues to attract critical infrastructure projects requiring validated 25-year performance warranties with global technical support.

(china 868 double wire fence)

FAQS on china 868 double wire fence

Q: What is china 868 double wire fence?

A: The China 868 double wire fence is a robust security fencing system manufactured in China. It features two parallel horizontal wires welded vertically into a grid pattern, providing high strength and impact resistance. This design is ideal for perimeter security in industrial zones, highways, and airports.

Q: Where is 868 double wire fence typically used?

A: 868 double wire fence is widely deployed for critical infrastructure protection. Common applications include securing military bases, prisons, power plants, and border areas. Its durability and anti-climb properties make it suitable for high-security locations requiring long-term reliability.

Q: Why choose a dedicated 868 double wire fence factory?

A: Selecting a specialized factory ensures precise manufacturing standards and quality control. Established factories offer tailored designs, bulk customization for large projects, and compliance with international certifications like ISO. This guarantees consistent material quality and structural integrity.

Q: How does 868 double wire mesh fence enhance security?

A: The dense mesh pattern deters climbing and cutting attempts effectively. Vertical rigidity absorbs impact from collisions while preventing hands or tools from gripping the fence. Galvanized or PVC-coated options provide corrosion resistance for harsh environments.

Q: What are key considerations for 868 double wire fence installation?

A: Proper ground anchoring with concrete footings prevents leaning or uplift. Spacing between fence posts must align with wind load calculations to maintain stability. Always verify local regulations for height requirements and safety standards before installation.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025