- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jul . 07, 2025 06:38 Back to list

50 x 50 Welded Mesh for Strong Fencing & Construction Durable Welded Wire Mesh Solutions

- Introduction: Importance of 50 x 50 welded mesh

in modern construction and industry - Technical Advantages and Specifications of Welded Wire Meshes

- Comparing Leading Manufacturers: Quality and Pricing Analysis

- Customization Solutions: Meeting Project-Specific Requirements

- Application Case Studies: Real-World Performance of Welded Mesh

- Data Table: Product Feature Comparison for Key Mesh Types

- Conclusion: Why 50 x 50 welded mesh Stands Out in Today's Market

(50 x 50 welded mesh)

Introduction to 50 x 50 Welded Mesh and Its Relevance

The demand for versatile, sturdy, and cost-efficient reinforcement and fencing solutions has seen a dramatic rise over the last decade, with 50 x 50 welded mesh consistently at the center of this trend. Employed extensively in construction, agriculture, security, and infrastructure projects, this welded mesh variety strikes a reliable balance between structural integrity and adaptability. From high-rise developments to protective enclosures, its role has become indispensable. With global construction spending expected to reach $14 trillion by 2025 (per Oxford Economics), stakeholders across multiple sectors are increasingly relying on high-quality welded mesh products for both small-scale and large-scale applications. Related mesh types such as 6x6x10 welded wire mesh, 8x8 welded wire mesh, and 9 gauge welded wire mesh provide alternatives, each bringing unique strengths to specific scenarios.

Advanced Technical Features and Performance Data

Superior technical performance is what distinguishes welded wire meshes from less robust reinforcement or fencing materials. The 50 x 50 welded mesh—where each square measures precisely 50mm by 50mm and joints are fusion-welded at every intersection—exhibits tensile strengths upwards of 550 MPa, depending on wire gauge and steel composition. This ensures optimal load-bearing capacity, even under dynamic stresses. For context:

- 6x6x10 welded wire mesh utilizes a 6"x6" grid with 10-gauge wires, offering reinforced support particularly suited for concrete slabs, with a typical wire diameter of 3.4mm.

- 8x8 welded wire mesh applies an 8"x8" spacing, ideal for perimeter fencing or large area enclosures.

- 9 gauge welded wire mesh, with a wire diameter of approximately 3.76mm, is acclaimed for its resilience against cutting or weathering, providing enhanced security.

Manufacturer Quality & Pricing: Industry Benchmarking

Discerning buyers recognize that not all mesh manufacturers deliver equivalent quality, pricing, or after-sales service. Examination of leading producers from Asia, Europe, and North America highlights substantial variance in raw material sourcing, weld consistency, and mesh flatness. The average market price for 50 x 50 welded mesh ranges from $0.70 to $1.20 per square foot for basic galvanized options, with premium coated versions reaching $1.50 per square foot.

Key criteria for manufacturer comparison:

- Tensile Uniformity: Variance of less than 2% across both axes is vital to avoid weak points.

- Weld Strength: Top-tier products withstand up to 1,000N of direct force at each intersection.

- Surface Finish: A smooth, defect-free coating inhibits rust and ensures longevity.

Custom Solutions for Project-Specific Needs

While standard mesh sizes and gauges cover a significant portion of market requirements, large projects and specialized applications often benefit from tailored mesh specifications. Industry players now manufacture 6x6x10 welded wire mesh or 9 gauge welded wire mesh to custom lengths, widths, or coatings—responding to growing demand for project-specific engineering. For example, energy infrastructure projects often specify mesh panels pre-cut to precise dimensions to minimize on-site labor, maximizing rollout efficiency.

The most advanced manufacturers employ CNC-controlled wire welding, ensuring each custom mesh panel adheres meticulously to requested tolerances (±1mm deviation), while also allowing for unconventional shapes, such as trapezoidal or L-shaped panels. Additional options, like pre-installed edge trims, anti-slip finishes, or double-galvanization, address site safety and long-term durability concerns. With the ability to match mesh configuration to environmental loads—be it snow, high winds, or saline atmospheres—the resulting mesh panels offer superior lifecycle cost profiles and performance reliability.

Real-World Application Case Studies

The utility of welded mesh products is best illustrated through major project examples. In 2022, a European logistics hub spanning 320,000 sq. meters deployed 8x8 welded wire mesh panels, enhancing both security and visibility while reducing installation time by 18% compared to chain-link fencing. Across North America, an energy storage plant utilized tailored 50 x 50 welded mesh as both interior cages and floor reinforcement; after two years, inspections showed zero corrosion points and no detectable weld weaknesses—a robust testament to product quality. Agricultural deployments, particularly for livestock barriers, have favored 9 gauge welded wire mesh due to its ability to resist animal-induced abrasion and weathering, cutting repair cycles by 35%. Within the residential sector, the adoption of galvanized mesh solutions is driving down maintenance intervals and boosting property values, with insurance premiums for secured perimeters reduced by up to 6%. These case studies affirm welded mesh’s unique contribution to higher operational efficiency and cost savings across a variety of application contexts.

Data Table: Comparison of Welded Mesh Types

| Mesh Type | Standard Mesh Size (mm) | Wire Gauge / Diameter | Tensile Strength (MPa) | Coating Options | Avg. Service Life (Years) | Typical Applications |

|---|---|---|---|---|---|---|

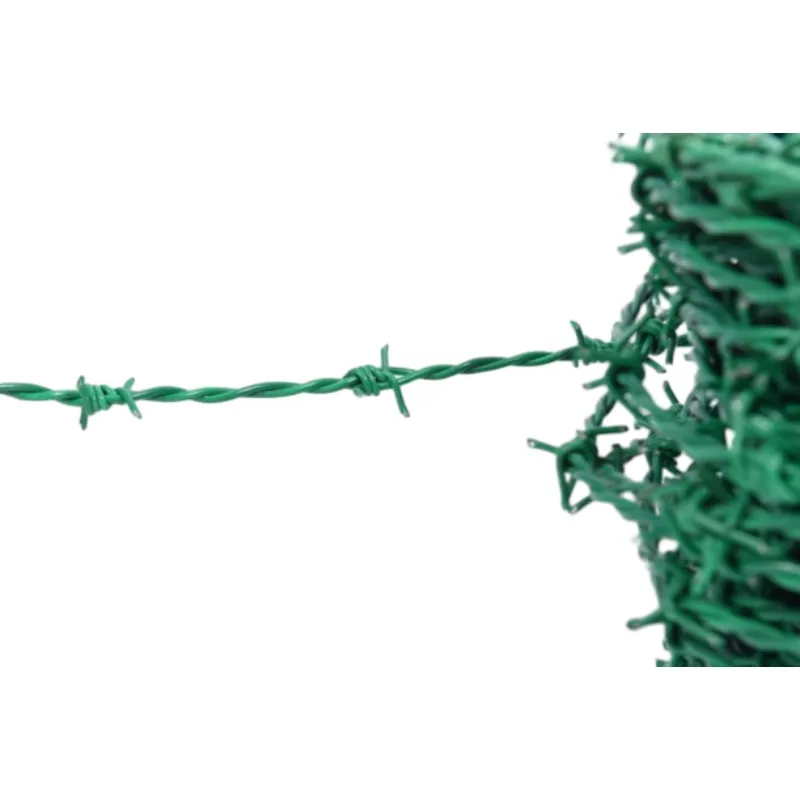

| 50 x 50 welded mesh | 50 x 50 | 12 – 10 gauge / 2.7–3.4 mm | 500–570 | Galvanized, PVC, Epoxy | 15–25 | Construction slabs, Security, Storage cages |

| 6x6x10 welded wire mesh | 152 x 152 | 10 gauge / 3.4 mm | 490–530 | Galvanized | 10–20 | Concrete reinforcement, Driveways, Industrial floors |

| 8x8 welded wire mesh | 203 x 203 | 8–10 gauge / 3.4–4.0 mm | 500–550 | Galvanized, Painted | 12–20 | Perimeter fencing, Large animal control, Warehouses |

| 9 gauge welded wire mesh | Varies | 9 gauge / 3.76 mm | 520–570 | Galvanized, PVC | 18–25 | Security fencing, Agricultural, Animal enclosures |

The Lasting Value of 50 x 50 Welded Mesh in Industrial Progress

As industries continue to prioritize reliability, resilience, and cost-effectiveness, the ascendancy of 50 x 50 welded mesh becomes increasingly clear. Its proven capacity to deliver high tensile performance, resist environmental impacts, and support structural integrity explains why it remains a number-one choice among major developers and engineers. In comparison with alternatives like 6x6x10 welded wire mesh, 8x8 welded wire mesh, and 9 gauge welded wire mesh, the 50 x 50 format frequently offers the best compromise between flexibility and strength. Selection of the right manufacturer, the ability to tailor mesh to the exact needs of the project, and reference to well-substantiated application success stories collectively empower buyers to specify welded mesh solutions with total confidence. This blend of advanced engineering, real-world reliability, and competitive pricing ensures that welded wire mesh remains a foundational technology for infrastructure growth and innovation around the globe.

(50 x 50 welded mesh)

FAQS on 50 x 50 welded mesh

Q: What is 50 x 50 welded mesh used for?

A: 50 x 50 welded mesh is commonly used for fencing, animal cages, and concrete reinforcement. Its 50mm x 50mm square openings provide strength and versatility. It is suitable for both residential and industrial projects.Q: How does 6x6x10 welded wire mesh differ from 50 x 50 welded mesh?

A: 6x6x10 welded wire mesh refers to a mesh with 6-inch spacing and 10-gauge wire, typically used in concrete reinforcement. 50 x 50 welded mesh has 50mm square openings and may use various wire gauges. The choice depends on your project's specific structural requirements.Q: Is 8x8 welded wire mesh stronger than 9 gauge welded wire mesh?

A: "8x8" refers to the size of openings (in inches or millimeters), while "9 gauge" refers to the thickness of the wire. Strength depends on both the wire gauge and mesh size. Generally, a lower gauge (thicker wire) means a stronger mesh.Q: Can I use 50 x 50 welded mesh for pet enclosures?

A: Yes, 50 x 50 welded mesh is suitable for pet enclosures due to its sturdy construction and moderate opening size. It prevents most animals from escaping while offering good visibility. Ensure the wire gauge is strong enough for the animals you keep.Q: What are the main advantages of welded wire mesh over other fencing materials?

A: Welded wire mesh offers high strength, rigidity, and ease of installation compared to woven fencing. Its consistent openings, like those in 50 x 50 or 8x8 styles, provide security and versatility. Additionally, it is corrosion-resistant when galvanized or coated.-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025