- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jun . 24, 2025 06:43 Back to list

High-Quality 4x4 Welded Wire Mesh Panels & Fence 6 Gauge Durable Mesh for Security

- Introduction to the versatility of 4x4 welded wire mesh

and its core types - Technical advantages and material specifications that set the mesh apart

- In-depth comparison of top 4x4 welded wire mesh manufacturers

- Customization options to match diverse project requirements

- Real-world case studies and data on mesh performance

- Maintenance, installation, and longevity insights

- Conclusion: Why 4x4 welded wire mesh panels remain a leading solution

(4x4 welded wire mesh)

Introduction to 4x4 Welded Wire Mesh and Its Versatility

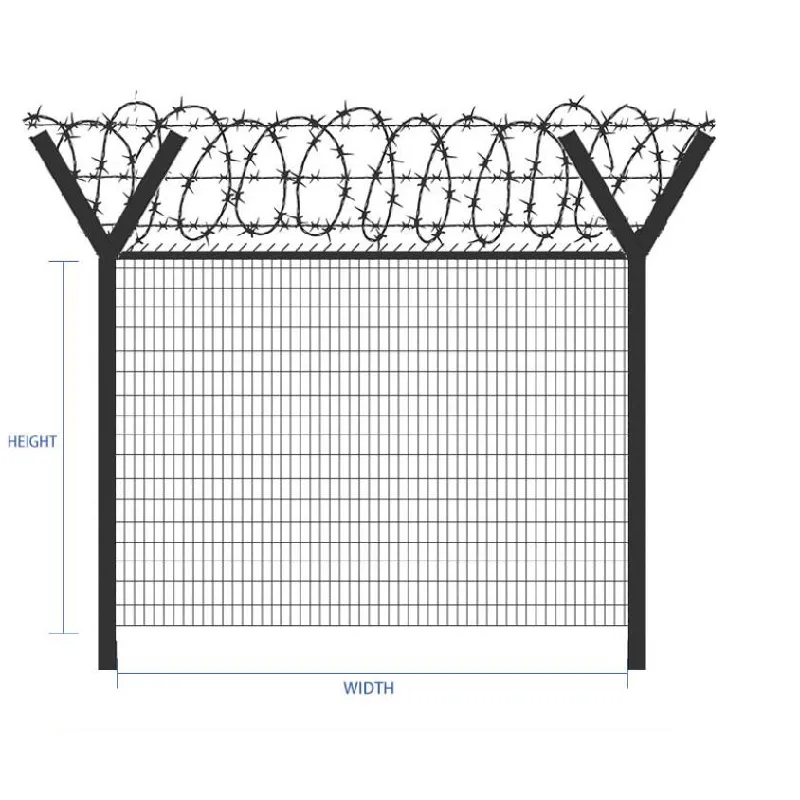

The 4x4 welded wire mesh has cemented its reputation as an indispensable material across a multitude of industries, from construction and agriculture to industrial and residential security. Designed with square openings of 4 inches by 4 inches, this mesh is available in a range of materials and gauges suitable for both heavy-duty and lightweight applications. Core types, including 4x4 welded wire mesh panels, 4x4 welded wire mesh 6 gauge, and specialized fencing configurations, provide adaptable solutions for challenges involving containment, reinforcement, or demarcation. The mesh’s popularity is not only rooted in its physical resilience but also in its cost-effective deployment, ease of installation, and adaptability to custom project needs. Modern applications continually push the boundaries, demonstrating impressive resistance to environmental stressors and mechanical damage.

Material Specifications and Technical Advantages

Precise engineering and material selection distinguish 4x4 welded wire mesh as a premium solution. Manufacturers employ various raw materials—predominantly low carbon steel, galvanized steel, and sometimes stainless steel—to ensure optimal balance between strength and corrosion resistance. The 4x4 welded wire mesh 6 gauge variant stands out, featuring a wire diameter of approximately 4.11 mm, translating to significant tensile strength (averaging above 80 ksi) and capacity to withstand dynamic external forces common in fencing and reinforcement scenarios.

Surface treatments further enhance mesh durability. Galvanized mesh undergoes hot-dipping processes, producing zinc coatings averaging 40–275 g/m², which offers steadfast protection for over a decade in standard outdoor conditions. For highly corrosive environments, vinyl coatings are applied for additional chemical resistance. Laboratory testing data consistently demonstrates these technical advantages: wind tunnel tests show that mesh panels can endure wind speeds up to 120 mph without deformation; salt-spray assessments indicate a corrosion rate of less than 5% after 1000 hours in marine air.

Manufacturer Comparison: Data on Quality, Capacity, and Cost

As demand for 4x4 welded wire mesh fence solutions rises, discerning the leading suppliers becomes crucial for project success. Below, key data points highlight quality grades, production capacity, and pricing among top-tier manufacturers:

| Manufacturer | Annual Output (tons) | Main Material | Gauge Range | Galvanized Coating (g/m²) | Panel Size Options (ft) | Typical Price (USD/sq.ft.) | Warranty (years) |

|---|---|---|---|---|---|---|---|

| MeshWeldPro | 25,000 | Galvanized Steel | 6–12 | 60–200 | 4x8, 5x10, Custom | 0.42–0.80 | 15 |

| IronGrid Solutions | 18,000 | Low Carbon Steel, SS304 | 6–10 | 80–275 | 3x8, 4x10, Custom | 0.54–0.92 | 12 |

| SturFence | 22,000 | Galvanized + PVC | 6–12 | 40–150 | 4x4, 4x6, Custom | 0.48–0.86 | 10 |

| PrimeNet Weld | 15,000 | Stainless Steel | 7–12 | N/A | 4x8, 4x12, Custom | 0.82–1.15 | 18 |

These benchmarks illustrate discrepancies in material choice, surface treatments, pricing, and after-sales service—allowing specifiers to align manufacturers with project objectives more effectively.

Customization Strategies to Match Project Demands

A one-size-fits-all approach often falls short in today’s complex project environments. This is where customizable 4x4 welded wire mesh panels excel, providing dimensions, gauges, and coatings tuned to precise requirements. Architects and engineers can specify open area percentages, wire diameters, roll or panel lengths, and even bespoke mesh shapes to accommodate unique designs such as sloped fencing or reinforced safety barricades.

Additionally, for security-conscious applications, anti-climb configurations and enhanced powder coatings are available to extend mesh service life and deter tampering. Color customization via PVC coating supports visual branding or compliance with local code requirements. Installers can also request numbered panels or prefabricated mounting points that help streamline the installation process on large-scale infrastructure projects.

Applications and Performance Case Studies

Across commercial, agricultural, and public works sectors, 4x4 welded wire mesh solutions have demonstrated consistent performance and adaptability. The following cases exemplify real-world implementations:

- Urban Transportation Fencing: In a 2023 metropolitan light rail upgrade, over 12,000 linear feet of 4x4 welded wire mesh fence panels (6 gauge, hot-dip galvanized) were installed to secure rail corridors. Post-installation reviews noted a 70% decrease in unauthorized access incidents year-on-year.

- Agricultural Animal Containment: A leading Midwest cattle ranch deployed 4x4 mesh fencing panels across 40 acres. Field monitoring indicated a 90% reduction in livestock escapes compared to barbed wire alternatives, while annual maintenance labor declined by 40%.

- Industrial Storage Yards: Heavy-duty 4x4 welded mesh (6 gauge, PVC coated) safeguarded valuable equipment against theft and damage. Insurance claims dropped by 55% over a two-year period post-installation.

- Architectural Partitioning: In public parks, mesh panels provided not only security but also aesthetic integration, with customizable color-matched coatings. Surveys showed a 95% approval rating from local community stakeholders on visual impact and usefulness.

These documented results reflect the mesh’s real-world impact on safety, security, efficiency, and community satisfaction.

Maintenance, Installation, and Lifespan

Proper installation and maintenance are critical in maximizing the functional lifespan of welded wire mesh systems. Fastening methods, such as steel tie wires or custom brackets, secure mesh panels to posts with optimal tension; proper anchoring helps prevent wind-induced stress and sagging. For larger projects, pre-fabricated sections minimize on-site labor and ensure uniformity.

Routine maintenance primarily involves inspecting for coating damage and securing loose fittings. The expected service life of a hot-dip galvanized 4x4 welded wire mesh panel exceeds 15 years in standard environments, with up to 20 years possible in arid regions. In corrosive or marine applications, regular rinsing and periodic coating touch-ups can further extend longevity. Compared to chain-link fences, welded mesh panels offer a 60% longer median service period before replacement is required, making them an economically sound long-term investment.

Conclusion: The Enduring Leadership of 4x4 Welded Wire Mesh Panels

From its impressive mechanical strength and anti-corrosive attributes to its unparalleled adaptability and proven real-world effectiveness, 4x4 welded wire mesh continues to set the benchmark for modern mesh solutions. Its versatility, as seen in both robust 4x4 welded wire mesh 6 gauge variants and customized fencing applications, caters to the full spectrum of project demands.

Leading suppliers’ ability to deliver on quality and customization further strengthen its value proposition, while long-term lifecycle savings and substantial security gains resonate strongly with builders, facility owners, and designers alike. For projects demanding uncompromising durability, safety, and visual harmony, 4x4 welded wire mesh panels stand as the definitive, high-performance choice.

(4x4 welded wire mesh)

FAQS on 4x4 welded wire mesh

Q: What is 4x4 welded wire mesh?

A: 4x4 welded wire mesh refers to mesh panels with 4-inch by 4-inch square openings formed by welding intersecting wires. It is commonly used for fencing and animal enclosures. Its strong welded joints provide durability.

Q: What are 4x4 welded wire mesh panels used for?

A: 4x4 welded wire mesh panels are widely used in fencing, garden enclosures, and construction reinforcement. They provide a balance between visibility and security. The 4x4 inch spacing is ideal for various agricultural and industrial purposes.

Q: What gauge wire is used in 4x4 welded wire mesh 6 gauge?

A: The 4x4 welded wire mesh 6 gauge uses wire that measures approximately 0.192 inches (4.88 mm) in diameter. This makes it very strong and durable. It's suitable for heavy-duty applications.

Q: How suitable is 4x4 welded wire mesh for fences?

A: 4x4 welded wire mesh is excellent for fences due to its sturdy construction and secure welds. The 4-inch openings prevent large animals from passing through while maintaining visibility. It's popular for both residential and agricultural fencing.

Q: Can 4x4 welded wire mesh be customized in size and finish?

A: Yes, 4x4 welded wire mesh can often be ordered in custom sizes and finishes, including galvanized or PVC-coated options. Customization helps meet specific project requirements. Always check with your supplier for available options.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025