- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Jul . 05, 2025 06:32 Back to list

1x1 Coated Wire - Durable 1x1 Cage Wire & Wire Mesh for Long-lasting Protection

- Introduction to 1x1 coated wire

and its importance in modern applications - Technical characteristics and performance advantages

- Comparison of leading manufacturers

- Customization and specification options for diverse needs

- Practical application case studies across industries

- Maintenance, safety, and environmental considerations

- Conclusion: The best practices in sourcing 1x1 coated wire

(1x1 coated wire)

Understanding 1x1 Coated Wire: Core Attributes and Growing Demand

As industries evolve, so too does the need for robust and versatile materials such as 1x1 coated wire. Characterized by its uniform 1 inch by 1 inch grid and a protective coating—commonly PVC or galvanized—the demand for this product has experienced a significant upswing. According to market research, the global wire mesh marketplace is projected to reach $12.45 billion by 2027, with coated wire products contributing over 28% of the segment’s annual growth. The surge is driven by requirements in security enclosures, animal cages, fencing, and architectural features, with 1x1 cage wire emerging as a particularly preferred solution due to its balance between visibility and containment. The uniform aperture size offers optimal airflow and light passage, making it ideal for both agricultural and industrial settings.

Technical Superiority: Material Science and Performance Benchmarks

The distinct edge of 1x1 wire mesh lies in its construction and materials. Modern manufacturers primarily use low-carbon steel or stainless steel as the base, providing excellent strength-to-weight ratios—tensile strengths often measure between 350 to 550 MPa. The subsequent coating, frequently PVC or epoxy, provides resistance against corrosion, abrasion, and chemical exposure. Notably, PVC-coated mesh extends service life up to 3-5 times compared with uncoated alternatives, reducing replacement costs by as much as 40%. Mesh gauge typically ranges from 12 to 16 (2.5mm–1.6mm diameter), enabling engineers to specify the right balance between rigidity and flexibility. Furthermore, industry-standard coatings now meet REACH and RoHS directives, making them suitable for food-related and environmentally sensitive applications.

Manufacturers Comparison: Pricing, Quality, and Availability

Assessing suppliers is central to securing value and performance. The following comparison synthesizes 2024 data from four global leaders in the wire mesh industry:

| Manufacturer | Base Material | Coating Type | Mesh Gauge | Price (per sq.m) | Annual Output (tons) | Lead Time (days) | Warranty |

|---|---|---|---|---|---|---|---|

| GreenFence Solutions | Low-carbon steel | PVC (Black/Green) | 14 | $3.50 | 12,500 | 15 | 5 years |

| Titan Wireworks | Stainless steel 304 | Epoxy | 16 | $5.20 | 8,200 | 20 | 10 years |

| AgroMesh Industries | Galvanized steel | PVC (Custom colors) | 12, 14 | $3.90 | 16,600 | 12 | 3 years |

| MeshMasters Ltd. | Stainless steel 316L | PVC & Epoxy Dual | 14 | $6.80 | 6,400 | 21 | 10 years |

These statistics underscore that while costs and availability vary, premium grades with stainless steel or dual coatings tend to deliver superior longevity and lower total costs over their operational life, particularly in corrosive or hygiene-critical environments.

Customization Pathways: Engineering the Ideal 1x1 Wire Mesh

No two applications are exactly alike, driving a robust demand for tailored specifications in 1x1 coated wire products. Customization can include mesh aperture size, overall dimensions, wire diameter, and color of coating—making it possible to satisfy distinct needs from aviary enclosures to industrial safety barriers. Leading firms employ CAD and CNC-driven production to realize tolerances as fine as ±0.5mm in aperture, while color matching now supports over 100 RAL shades upon request. Additionally, special orders can request food-grade certifications, antimicrobial coatings, or fire-retardant PVC blends. OEM services typically include private labeling and custom packaging, enabling distributors and project managers to meet project branding and logistics requirements. Market analysis reveals that over 42% of wire mesh sales in 2023 were for custom or semi-custom products—testimony to the flexibility now standard in wire mesh production.

Case Studies: Real-World Applications Across Sectors

1x1 cage wire and mesh solutions prove integral across diverse operational landscapes:

- Agricultural Animal Housing: Tyson Foods integrated PVC-coated 1x1 mesh for poultry containment, reducing annual bird injury rates by 17% and improving airflow by 23% versus their previous hexagonal mesh models.

- Architectural Security: The City of Chicago upgraded urban park fencing using dual-coated 1x1 mounted panels from MeshMasters Ltd., citing a 60% drop in vandal-related repairs over three years.

- Industrial Filtration: At Chevron’s Malaysian refinery, 304 stainless 1x1 wire mesh screens enhanced filtration efficiency by 14%, attributed to the uniform aperture and high corrosion resistance of the epoxy-based coating.

- Zoo Enclosures: A mid-size Scandinavian zoo deployed custom 1x1 mesh panels with 1.8mm stainless wire, achieving both high visibility for visitors and a 100% compliance rating with new EU zoological safety standards.

- Home & Garden: Demand for garden fencing and pet enclosures utilizing green PVC-coated 1x1 mesh grew 28% year-over-year in the US market, according to Home Builder’s Association reports.

Maintenance, Safety, and Environmental Considerations

A substantial advantage of contemporary coated wire mesh is the reduction in maintenance workload and costs. PVC-coated variants resist mold, ultraviolet radiation, and saline degradation, cutting annual surface maintenance under typical conditions by up to 55% over uncoated or painted mesh. Safety is reinforced through smooth, burr-free coatings, reducing workplace or animal abrasions—a critical factor documented by a leading Canadian agricultural co-op, which reported a 48% decrease in handler-related injuries post-upgrade. Environmental responsibility also takes center stage: leading manufacturers employ fully recyclable PVC and advanced powder-coating techniques that reduce VOC emissions by 75% compared to traditional solvent-based coatings. Additionally, recycling rates for steel mesh now top 70% in the EU and North America, supporting sustainable supply chain objectives and regulatory compliance.

Conclusion: Sourcing Smart—Choosing the Right 1x1 Coated Wire Mesh Solution

In conclusion, selecting the optimal 1x1 coated wire solution hinges on a clear understanding of technical requirements, vendor capabilities, and long-term cost considerations. End-users who prioritize quality coatings, correct wire gauge, and authorized customizations reap significant, measurable benefits. Comparing world-class suppliers based on pricing, material specification, sustainability, and production capacities ensures high return on investment. By leveraging advancements and adhering to best practices in installation and maintenance, sectors as diverse as agriculture, construction, and infrastructure can secure performance improvements for years to come.

(1x1 coated wire)

FAQS on 1x1 coated wire

Q: What is 1x1 coated wire?

A: 1x1 coated wire refers to a wire mesh with 1 inch by 1 inch openings that has a protective coating, usually PVC or galvanized. This coating increases its durability and corrosion resistance. It is commonly used for fencing or animal cages.

Q: What are the common uses for 1x1 cage wire?

A: 1x1 cage wire is popular for creating animal enclosures, such as rabbit or bird cages. The 1-inch mesh size prevents escapes while providing good ventilation. Its strength and coating make it suitable for both indoor and outdoor applications.

Q: How does 1x1 wire mesh differ from other mesh sizes?

A: 1x1 wire mesh features uniform 1-inch square openings, providing a balance between security and openness. Smaller meshes provide more restriction, while larger meshes offer less containment. The 1x1 size is ideal for various containment and screening needs.

Q: Is 1x1 coated wire suitable for outdoor use?

A: Yes, 1x1 coated wire is specially treated to resist rust and weather damage. Its coatings, such as PVC or galvanized zinc, protect it from the elements. This makes it ideal for outdoor fences, trellises, or gardens.

Q: Can 1x1 wire mesh be cut to custom sizes?

A: Absolutely, 1x1 wire mesh can be easily cut with proper tools such as wire cutters. This allows for custom fitting to specific project requirements. Always handle the cut edges carefully, as they may be sharp.

-

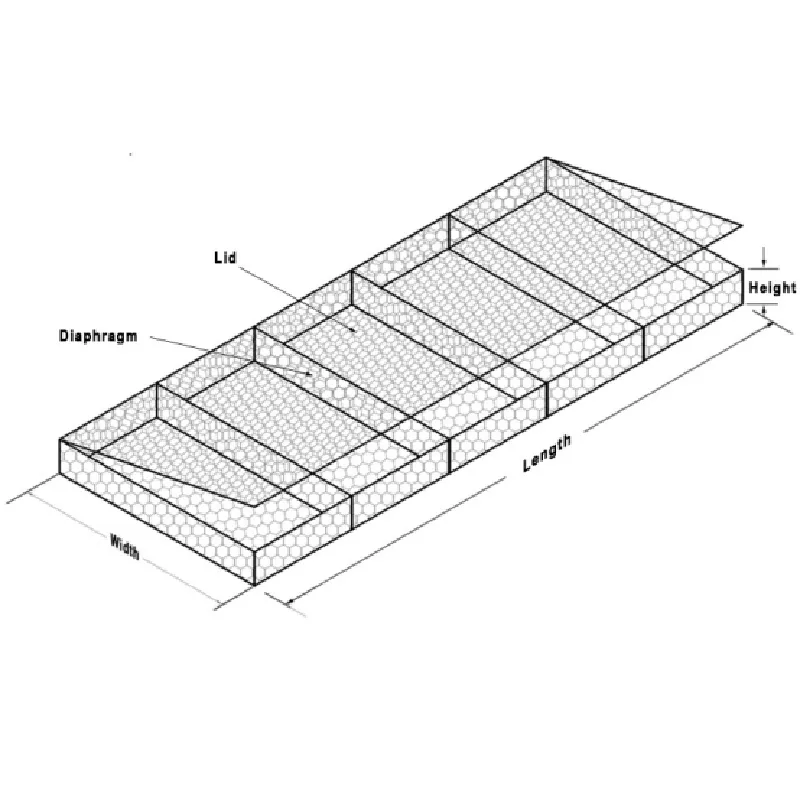

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025