- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Mar . 05, 2025 07:25 Back to list

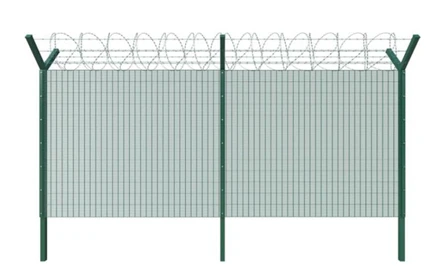

welded wire fence mesh

In terms of expertise, manufacturers of welded wire fence mesh are continually innovating to meet stringent industry standards and cater to the specific needs of different applications. The processes involved in creating these meshes, such as galvanization and coating, ensure that each panel withstands environmental pressures while maintaining structural integrity. This commitment to quality assures end-users of a product that performs reliably over extended periods, thus reducing maintenance costs and increasing the overall value derived from the purchase. Authoritativeness is reinforced through compliance with international standards. Many manufacturers adhere to protocols such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) which govern the quality and production processes of welded wire fence mesh. These standards guarantee that the product not only meets but often exceeds global expectations of performance and safety, making it a trusted choice for engineers and architects worldwide. Trustworthiness of welded wire fence mesh is further established through rigorous testing and field applications that validate its efficacy. The long-term use of this fencing material in diverse conditions—from temperate climates to harsh, corrosive environments—demonstrates its reliability and efficiency. Customer testimonials and case studies often highlight reduced life-cycle costs and heightened security outcomes, cementing their trust in the product. In essence, welded wire fence mesh embodies the ideal fusion of function and form, serving a wide array of purposes from protecting assets and ensuring safety to contributing to modern architectural designs. Its comprehensive advantages in durability, flexibility, and cost-efficiency position it as an indispensable choice for discerning stakeholders across various industries.

-

Comprehensive Guide to Wire Mesh Solutions: Security, Durability, and Customization

NewsAug.24,2025

-

Comprehensive Guide to Welded Fencing Solutions: Durability, Security, and Style

NewsAug.24,2025

-

Comprehensive Guide to Livestock Fence Panels: Safety and Efficiency for Your Animals

NewsAug.24,2025

-

Comprehensive Guide to Temporary Fencing Solutions: From Construction Sites to Events

NewsAug.24,2025

-

Hebei Dunqiang Hardware Mesh Co., Ltd. – Your Reliable Partner in Wire Mesh Solutions

NewsAug.24,2025

-

Hebei Dunqiang Hardware Mesh Co., Ltd. – A Leading Force in Wire Mesh China

NewsAug.24,2025