- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Dec . 14, 2024 07:52 Back to list

Best Practices for Welding Stainless Steel Wire Mesh in Various Applications

Welding Stainless Steel Mesh Techniques and Applications

Welding stainless steel mesh is a fundamental process in various industries due to its exceptional properties and versatility. Stainless steel, known for its resistance to corrosion, high strength, and durability, is a preferred material for many applications. In this article, we will explore the methods of welding stainless steel mesh, its benefits, and its wide-ranging applications.

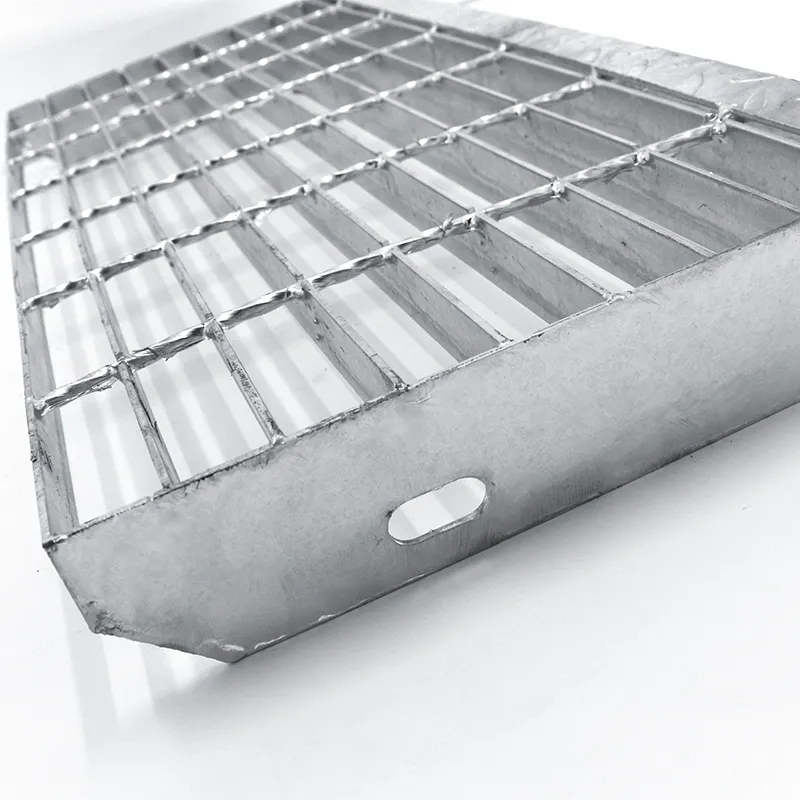

Understanding Stainless Steel Mesh

Stainless steel mesh is composed of woven wire or expanded metal, manufactured from stainless steel grades such as 304, 316, and 430. The selection of the grade depends on the specific application requirements, such as strength, resistance to oxidation, and exposure to different environmental conditions. The mesh is commonly used in filtration processes, architectural features, and various industrial applications.

Welding Techniques

1. TIG Welding (Tungsten Inert Gas Welding) TIG welding is one of the most commonly used methods for welding stainless steel mesh. This technique uses a non-consumable tungsten electrode to produce the weld. The process is controlled and precise, making it ideal for thin materials. The use of an inert gas shield (usually argon) prevents oxidation, helping to maintain the integrity of the stainless steel during the welding process.

2. MIG Welding (Metal Inert Gas Welding) MIG welding is another effective method for welding stainless steel mesh. This technique uses a continuous wire feed as the electrode and an inert gas to protect the weld zone from contamination. MIG welding is faster than TIG welding and is suitable for larger projects or thicker meshes. It offers high productivity and can create strong welds quickly.

3. Spot Welding Spot welding is frequently employed when working with stainless steel mesh, especially in manufacturing applications. It involves the use of two electrodes to generate heat at specific points, causing the mesh wires to fuse together. This technique is efficient for joining discrete sections of mesh and allows for high-speed production.

welding stainless steel mesh

4. Laser Welding For high-precision applications, laser welding provides an advanced solution. This technique uses a concentrated laser beam to melt the edges of the stainless steel mesh. It is suitable for delicate and intricate designs, offering minimal heat-affected zones, which is crucial when preserving the material properties.

Benefits of Welding Stainless Steel Mesh

- Corrosion Resistance Welding improves the structural integrity of stainless steel mesh while retaining its excellent resistance to rust and corrosion. - Strength and Durability Properly welded stainless steel mesh can withstand significant stress and last for years, making it an economically sound choice. - Versatility Welded stainless steel mesh is adaptable to various applications, from architecture to food processing and mining. - Aesthetic Appeal The smooth finish achieved through welding enhances the visual aspects of stainless steel mesh, making it suitable for decorative applications.

Applications of Welded Stainless Steel Mesh

Welded stainless steel mesh finds a wide array of applications across different sectors

- Industrial Filtration Used as filters in the food and beverage industry to prevent contamination while allowing for efficient liquid flow. - Security Fencing Provides a robust protective barrier in residential and commercial properties, enhancing security without compromising visibility. - Architectural Design Applied in decorative screens, railings, and facades, offering both function and style. - Mining and Construction Used to create sturdy barriers and screens for safety and operational efficiency.

In summary, welding stainless steel mesh is a critical process that combines technical expertise with practical application. Whether utilizing TIG, MIG, spot, or laser welding, the result is a material that is not only durable and versatile but also aesthetically pleasing. As industries continue to evolve, the demand for high-quality welded stainless steel mesh will remain strong, illustrating its enduring relevance in modern manufacturing and construction.

-

Versatile Sheep and Livestock Hurdles for Sale

NewsApr.14,2025

-

The Rise of BRC Fencing

NewsApr.14,2025

-

High-Quality Cattle and Horse Panels for Sale

NewsApr.14,2025

-

Durable Cattle Fencing Solutions

NewsApr.14,2025

-

Double Wire Fencing Solutions

NewsApr.14,2025

-

360 Degree Protection with 358 Anti-Climb Fences

NewsApr.14,2025