- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Дек . 16, 2024 16:32 Back to list

High-Quality Welded Wire Mesh Specifications and Applications for Various Industries

The Benefits and Applications of 3% 208% Welded Wire Mesh

Welded wire mesh is a versatile construction material widely used in various applications ranging from civil engineering to intricate decorative designs. One specific variant that has garnered attention is the 3% 208% welded wire mesh, known for its strength, durability, and design flexibility. This article delves into what this type of welded wire mesh is, its manufacturing process, applications, and the benefits it offers.

Understanding 3% 208% Welded Wire Mesh

The term 3% 208% refers to specific characteristics of the welded wire mesh. The 3% can denote the proportion of carbon content in the steel used to manufacture the mesh, which directly affects the mesh's tensile strength and flexibility. A 208% refers to the particular gauge or wire thickness, signifying its robustness and capability to withstand various loads.

Welded wire mesh is constructed by welding intersecting steel wires together in a grid pattern. This method of manufacturing enhances the structural integrity of the mesh, making it less likely to deform or rupture under stress. The welded intersections create a stable framework that ensures uniform distribution of loads across the surface.

Manufacturing Process

The manufacturing process of 3% 208% welded wire mesh is meticulous, maintaining strict quality controls to ensure a reliable end product. First, high-quality steel wires are drawn to the required gauge, incorporating a 3% carbon content for optimal performance. These wires are then arranged in a grid layout, typically with specified spacing, and welded at their intersections using advanced welding techniques.

The resulting mesh is then subjected to various treatments, such as galvanization or coating, to enhance its resistance to corrosion and weathering. This treatment is particularly vital for applications exposed to the elements, as it significantly extends the lifespan of the mesh.

Applications

The versatility of 3% 208% welded wire mesh makes it suitable for a wide range of applications

1. Construction It is widely used in reinforcing concrete for slabs, walls, and foundations, providing enhanced tensile strength and durability.

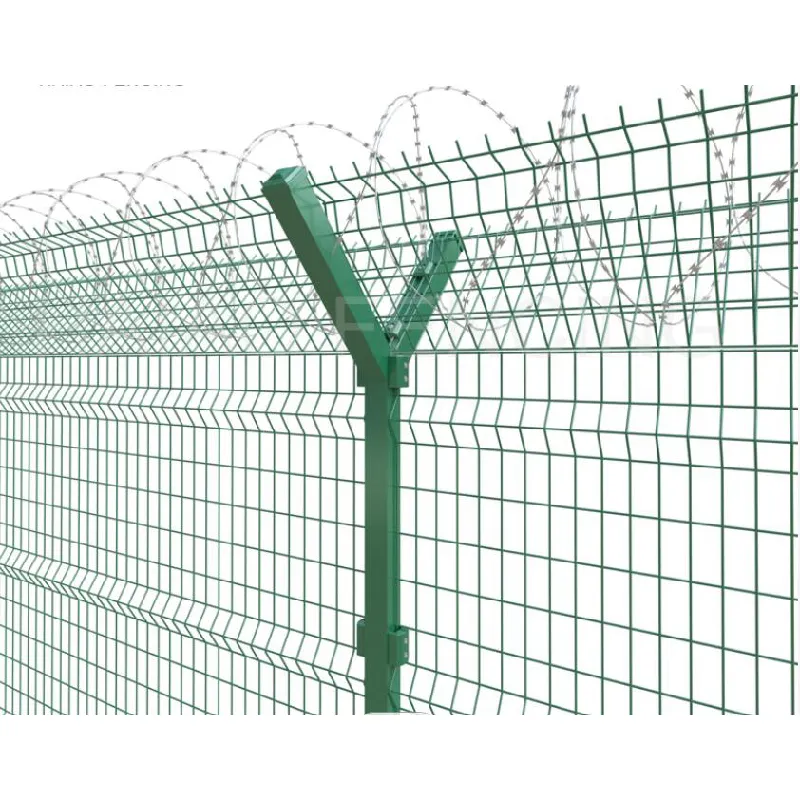

2. Fencing Due to its rigidity, this type of mesh is often employed in fencing applications, serving as a barrier for livestock, wildlife conservation areas, and construction sites.

3 8 welded wire mesh

4. Agricultural Settings Farmers utilize welded wire mesh for livestock enclosures, garden fencing, and supports for climbing plants.

5. Architectural Features The aesthetic appeal of this mesh also allows it to be used in decorative applications, such as railings, partitions, and even art installations.

Benefits

The benefits of using 3% 208% welded wire mesh are numerous and significant

- Strength and Durability The structural integrity of welded wire mesh makes it an ideal choice for load-bearing applications, ensuring long-lasting performance.

- Cost-Effectiveness Given its ability to enhance the strength of concrete structures, this mesh can contribute to reduced material costs and overall project expenses.

- Ease of Installation The mesh is generally lightweight and manageable, simplifying the installation process for construction workers.

- Versatility Its varied applications demonstrate its adaptability, making it suitable for both residential and industrial projects.

- Environmental Resistance With proper treatment, welded wire mesh is highly resistant to corrosion and weathering, enabling extended lifespan even under challenging conditions.

Conclusion

3% 208% welded wire mesh represents a powerful tool in the construction and design industries, combining strength, versatility, and cost-effectiveness. Its broad range of applications—from reinforcing concrete to providing safety barriers—illustrates its importance in various sectors. By understanding the characteristics and benefits of this type of mesh, builders, designers, and farmers can make informed choices that enhance their projects and operations. As industries continue to evolve, the demand for such innovative materials is likely to grow, paving the way for more advanced applications in the future.

-

Your Ultimate Solution for Australian Temporary Fencing

NewsMay.14,2025

-

The Ultimate Guide to Crowd Control Barriers: Secure Your Events with Ease

NewsMay.14,2025

-

Secure Your Livestock with High-Quality Livestock Fence Panels

NewsMay.14,2025

-

Enhance Your Livestock Management with Top-Quality Cattle Fences

NewsMay.14,2025

-

Enhance Security and Safety with Temporary Fencing Solutions

NewsMay.14,2025

-

Corral Gates

NewsMay.14,2025