- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Дек . 17, 2024 16:52 Back to list

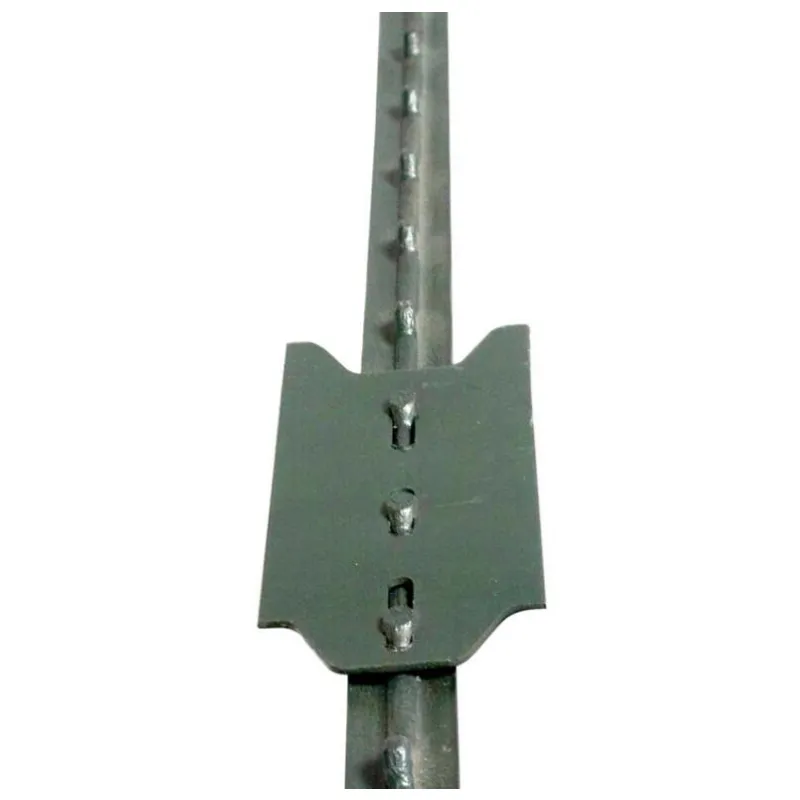

1 2 x 1 x 36 welded wire

Understanding 1% 202% x 1% x 36 Welded Wire Applications and Benefits

Welded wire has become an essential component in various industries due to its strength, durability, and versatility. Among the myriad of options available in the market, the “1% 202% x 1% x 36 welded wire” stands out. In this article, we will explore what this specific type of welded wire is, its composition, applications, and the benefits it brings to various sectors.

What is 1% 202% x 1% x 36 Welded Wire?

At its core, welded wire is made from steel wires that are electrically welded at their intersections, creating a grid-like structure. The designation “1% 202% x 1% x 36” refers to specific measurements and materials that define the wire’s characteristics.

- 1% and 202% These figures can indicate the wire gauge and tensile strength. A 1% measurement often refers to a specific percentage of carbon in the wire, which significantly affects its hardness and flexibility. The 202% could indicate the yield strength, meaning how much stress the wire can withstand before deforming. - 1% x 36 These are dimensions that specify the width and length of the wire mesh. In practical terms, this sets the physical size of the completed welded wire panel, making it critical for various applications, from fencing to reinforcement in construction.

Applications

Welded wire is utilized across numerous applications, thanks to its adaptability. Below are some of the most common uses

1. Construction In the building industry, welded wire is often used as reinforcement in concrete structures, providing necessary tensile strength to support heavy loads and resist cracking.

2. Fencing Given its robust construction, 1% 202% x 1% x 36 welded wire is frequently employed in the creation of fences for residential, agricultural, and commercial properties. Its strength is vital for maintaining security and keeping livestock contained.

3. Agriculture Farmers use welded wire for various purposes, including creating animal enclosures, reinforcing structures such as silos, and developing trellises for climbing plants.

4. Industrial Applications The durability and resistance to corrosion make welded wire an ideal choice for industrial applications, including the construction of cages, racks, and storage bins in warehouses and manufacturing facilities.

1 2 x 1 x 36 welded wire

5. DIY Projects Homeowners and hobbyists also benefit from the versatility of welded wire. It can be utilized in crafts, garden projects, and constructing customized fencing solutions.

Benefits of 1% 202% x 1% x 36 Welded Wire

The advantages of adopting this type of welded wire in various fields go beyond its mere structural benefits. Here are some key points to consider

1. Strength and Durability One of the main benefits of welded wire is its high tensile strength, which can withstand significant loads and stress. This ensures longevity and reliability in construction and fencing applications.

2. Cost-Effectiveness Compared to other forms of wire or fencing systems, welded wire is often more economical. Its durability means less frequent replacement, contributing to lower overall costs.

3. Versatility With its various applications, welded wire can adapt to multiple needs, making it an excellent investment for both industrial and residential projects.

4. Ease of Installation Typically, welded wire panels come ready to use, which means they can be quickly installed, saving time and labor costs.

5. Environmental Resistance Many welded wire products are coated or treated to resist rust and corrosion, making them suitable for outdoor and harsh environments.

Conclusion

The 1% 202% x 1% x 36 welded wire is more than just a building material; it is an essential component contributing to safety, security, and efficiency across various industries. Understanding its composition, applications, and inherent benefits can help businesses and individuals make informed decisions about the materials they choose for their projects. As industries continue to evolve, the demand for robust solutions like welded wire will only grow, making it a timeless choice in construction, agriculture, and beyond.

-

Versatile Sheep and Livestock Hurdles for Sale

NewsApr.14,2025

-

The Rise of BRC Fencing

NewsApr.14,2025

-

High-Quality Cattle and Horse Panels for Sale

NewsApr.14,2025

-

Durable Cattle Fencing Solutions

NewsApr.14,2025

-

Double Wire Fencing Solutions

NewsApr.14,2025

-

360 Degree Protection with 358 Anti-Climb Fences

NewsApr.14,2025