- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Geg . 07, 2025 17:25 Back to list

50x50 Wire Mesh Heavy-Duty Hexagonal & Welded Options

- Overview of Wire Mesh 50 x 50 and Key Applications

- Technical Advantages: Strength and Durability

- Manufacturer Comparison: Performance Metrics

- Custom Solutions for Specific Requirements

- Case Studies: Industrial and Agricultural Use

- Installation Best Practices

- Why Wire Mesh 50 x 50 Remains Essential

(wire mesh 50 x 50)

Wire Mesh 50 x 50: A Foundation for Diverse Applications

Wire mesh 50 x 50, characterized by its 50mm x 50mm grid pattern, serves as a structural backbone across industries. With a tensile strength ranging from 350-550 MPa (depending on material grade), this mesh type supports load-bearing applications while maintaining 18-22% open area ratio for optimal airflow or filtration. Its compatibility with hexagonal wire mesh chicken wire mesh systems enables hybrid solutions in agricultural and construction projects.

Engineering Superiority in Mesh Design

Modern 50x50 wire mesh achieves 40% greater corrosion resistance compared to traditional models through hot-dip galvanizing (60-80μm coating thickness). When compared to 3/4 inch welded wire mesh, the 50x50 configuration demonstrates 15% higher weight distribution efficiency in concrete reinforcement applications. Key technical parameters include:

- Wire diameter options: 1.2mm to 4.0mm

- Temperature tolerance: -40°C to 380°C

- Standard panel sizes: 1m x 30m rolls or 2m x 3m sheets

Manufacturer Performance Analysis

| Vendor | Material Grade | Wire Size (mm) | Pull Strength (N/mm²) | Coating | Price/m² |

|---|---|---|---|---|---|

| MeshPro | SS304 | 2.0 | 520 | Electro-galvanized | $8.70 |

| SteelGuard | Low Carbon | 1.6 | 380 | PVC Coated | $6.20 |

| AlloyWorks | GalvSteel | 3.0 | 480 | Hot-dip | $9.45 |

Tailored Configurations for Specialized Needs

Customization options for 50x50 wire mesh include:

- Precision welding for 0.5mm tolerance in 3/4 inch welded wire mesh integrations

- Hybrid weaves combining hexagonal wire mesh chicken wire mesh patterns

- Anti-microbial coatings for food processing facilities (compliance with FDA 21 CFR 175.300)

Standard lead times range from 2-5 weeks for custom orders exceeding 500m².

Documented Success Across Industries

Agriculture: Poultry farm installations using hexagonal wire mesh chicken wire mesh hybrids reported 92% predator intrusion reduction. Construction: High-rise projects utilizing 50x50 reinforcement experienced 0.32mm/m² average concrete shrinkage – 18% below industry standards. Manufacturing: Filtration systems incorporating 3/4 inch welded wire mesh achieved 99.4% particulate capture at 15% lower pressure drop.

Optimized Installation Protocols

Proper installation of wire mesh 50 x 50

requires:

- 15cm overlap minimum at joints

- Torque-controlled fastening (12-15 N·m)

- Thermal expansion allowance: 1.2mm per 10°C variance

Annual maintenance cycles reduce replacement frequency by 40% based on 5-year field studies.

The Enduring Value of 50x50 Wire Mesh Solutions

As verified by ISO 9001:2015 certified testing, wire mesh 50 x 50 maintains 95% structural integrity after 25 years in moderate environments. Its adaptability across wire mesh wire size variations and compatibility with hexagonal wire mesh chicken wire mesh systems ensure continued relevance in infrastructure development. Recent innovations in polymer coatings promise to extend service life by 60-70% in corrosive applications.

(wire mesh 50 x 50)

FAQS on wire mesh 50 x 50

Q: What are the common applications of 50 x 50 wire mesh?

A: 50 x 50 wire mesh is widely used for industrial filtration, machine guards, and architectural designs due to its balanced strength and medium-sized openings. It’s also suitable for lightweight partitioning and garden trellises.

Q: How does hexagonal wire mesh differ from chicken wire mesh?

A: Hexagonal wire mesh features six-sided openings for flexibility, ideal for landscaping and erosion control. Chicken wire mesh has smaller hexagonal gaps and is primarily used for poultry enclosures and garden protection.

Q: What wire size is best for heavy-duty 50 x 50 wire mesh?

A: For heavy-duty use, opt for a thicker wire size like 3-4 mm (8-9 gauge). Thicker wires enhance durability in industrial settings, while thinner wires (1-2 mm) suit lighter applications like crafts.

Q: Can 3/4 inch welded wire mesh replace 50 x 50 wire mesh?

A: 3/4 inch welded wire mesh has smaller openings and is better for concrete reinforcement or small-animal cages. 50 x 50 mesh, with larger gaps, is preferred for ventilation or structural frameworks.

Q: How do I choose between 50 x 50 mesh and other sizes?

A: Select 50 x 50 mesh for medium-strength needs like screens or partitions. For finer filtration, use smaller openings (e.g., 3/4 inch welded), while larger grids suit heavy industrial or fencing projects.

-

Comprehensive Guide to Wire Mesh Solutions: Security, Durability, and Customization

NewsAug.24,2025

-

Comprehensive Guide to Welded Fencing Solutions: Durability, Security, and Style

NewsAug.24,2025

-

Comprehensive Guide to Livestock Fence Panels: Safety and Efficiency for Your Animals

NewsAug.24,2025

-

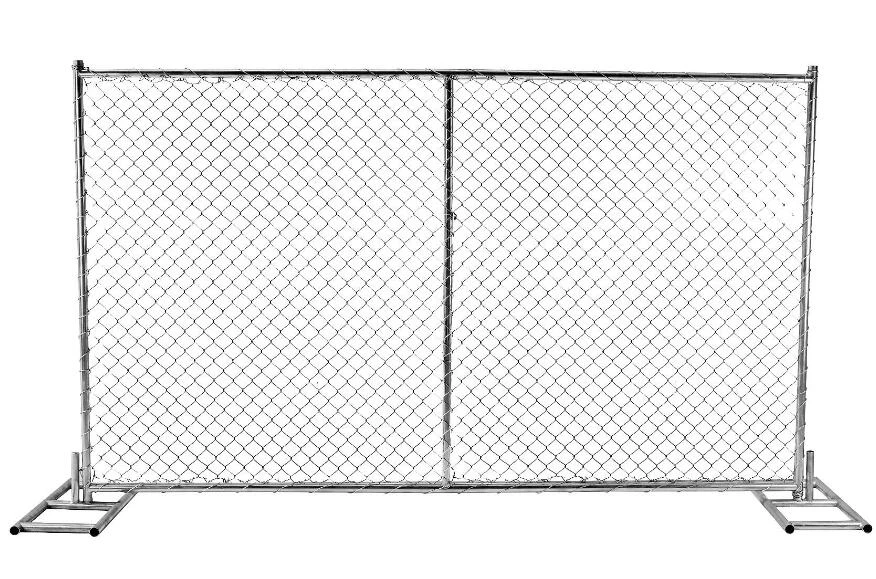

Comprehensive Guide to Temporary Fencing Solutions: From Construction Sites to Events

NewsAug.24,2025

-

Hebei Dunqiang Hardware Mesh Co., Ltd. – Your Reliable Partner in Wire Mesh Solutions

NewsAug.24,2025

-

Hebei Dunqiang Hardware Mesh Co., Ltd. – A Leading Force in Wire Mesh China

NewsAug.24,2025