- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

nov. . 15, 2024 04:38 Back to list

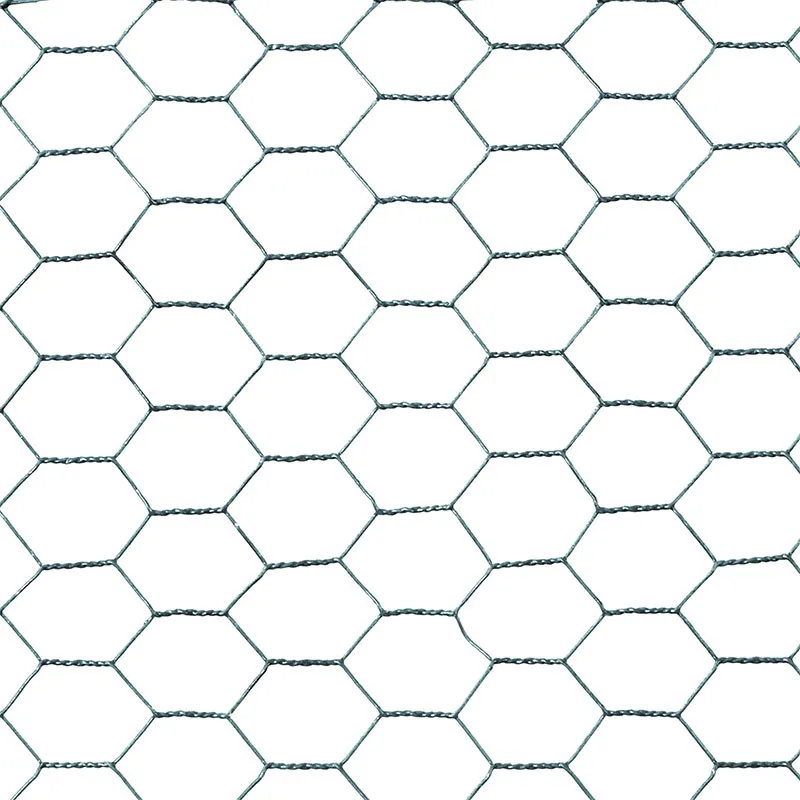

epoxy coated wire mesh for concrete

Epoxy Coated Wire Mesh for Concrete Enhancing Strength and Durability

In the construction industry, the need for materials that enhance the strength and durability of concrete structures cannot be overstated. One such innovative solution is epoxy coated wire mesh, which has gained popularity for its unique properties and advantages. This article explores the features, benefits, applications, and installation of epoxy coated wire mesh for concrete, highlighting its significance in modern construction.

Understanding Epoxy Coated Wire Mesh

Epoxy coated wire mesh is essentially steel wire mesh that has been coated with a layer of epoxy resin. This dual-layer construction not only strengthens the wire mesh itself but also provides an additional protective barrier against environmental factors. The epoxy coating effectively prevents corrosion, rusting, and wear, which can significantly compromise the integrity of the steel.

Key Benefits of Epoxy Coated Wire Mesh

1. Corrosion Resistance One of the primary benefits of epoxy coated wire mesh is its resistance to corrosion. Unlike uncoated steel that can easily succumb to moisture and autooxidation, the epoxy coating acts as a protective shield, extending the lifespan of the wire mesh. This is particularly crucial in environments exposed to harsh weather conditions, chemicals, and moisture.

2. Enhanced Bonding The textured surface of epoxy coated wire meshing allows for better adhesion with concrete. This enhances the bond between the mesh and the concrete, leading to improved structural integrity. As a result, projects using epoxy coated mesh can achieve higher load-bearing capacities.

3. Versatility Epoxy coated wire mesh is versatile and can be used in various construction applications. It is ideal for reinforcing concrete in slabs, walls, pavements, and precast concrete products. Its adaptability to different structural requirements makes it a preferred choice among engineers and architects.

4. Reduced Maintenance Costs Thanks to its durability and resistance to environmental wear, structures reinforced with epoxy coated wire mesh typically require less maintenance over time. This translates to cost savings for construction firms and property owners alike, as they are less likely to encounter issues related to rust or structural failure.

epoxy coated wire mesh for concrete

5. Environmentally Friendly With growing environmental concerns, using epoxy coated wire mesh represents a step towards greener construction practices. The longevity and reduced need for repairs contribute to sustainability by minimizing waste and resource consumption over the structure's life cycle.

Applications in Construction

Epoxy coated wire mesh is widely utilized across various sectors in the construction industry. It plays a critical role in

- Residential Construction For reinforcing floors, walkways, and driveways, providing enhanced load capacity and durability. - Commercial Buildings Used in concrete slabs and foundations, contributing to the longevity of commercial structures. - Infrastructure Projects Essential in roads, bridges, and tunnels, where high strength and corrosion resistance are paramount. - Industrial Applications Ideal for reinforcing concrete bins, silos, and tanks in industrial settings where durability is critical.

Installation Process

The installation of epoxy coated wire mesh is relatively straightforward. The process typically involves

1. Preparation of the Site Ensure the area where the mesh will be installed is clean and free of debris. 2. Cutting and Shaping the Mesh Depending on the specifications of the project, the wire mesh may need to be cut to fit the dimensions required. 3. Laying the Mesh Place the mesh at the designated height required for reinforcement. 4. Securing the Mesh Use appropriate methods, such as tying or welding, to secure the mesh in position. 5. Pouring Concrete Finally, the concrete mix is poured over the reinforced area, ensuring that the mesh is adequately covered.

Conclusion

In conclusion, epoxy coated wire mesh represents a significant advancement in construction technology. Its corrosion resistance, enhanced bonding capabilities, versatility, and reduced maintenance costs make it an excellent choice for reinforcing concrete structures. As the construction industry continues to focus on durability and sustainability, the adoption of epoxy coated wire mesh is likely to increase, contributing to stronger and longer-lasting infrastructures. Whether in residential, commercial, or industrial applications, the benefits it offers position it as a crucial material in the modern construction landscape.

-

Versatile Sheep and Livestock Hurdles for Sale

NewsApr.14,2025

-

The Rise of BRC Fencing

NewsApr.14,2025

-

High-Quality Cattle and Horse Panels for Sale

NewsApr.14,2025

-

Durable Cattle Fencing Solutions

NewsApr.14,2025

-

Double Wire Fencing Solutions

NewsApr.14,2025

-

360 Degree Protection with 358 Anti-Climb Fences

NewsApr.14,2025