- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Srp . 19, 2025 03:40 Back to list

Wholesale 358 Anti-Climb Fence | High Security & Durable

Redefining Perimeter Security: An In-depth Look at 358 Anti-Climb Fence Technology

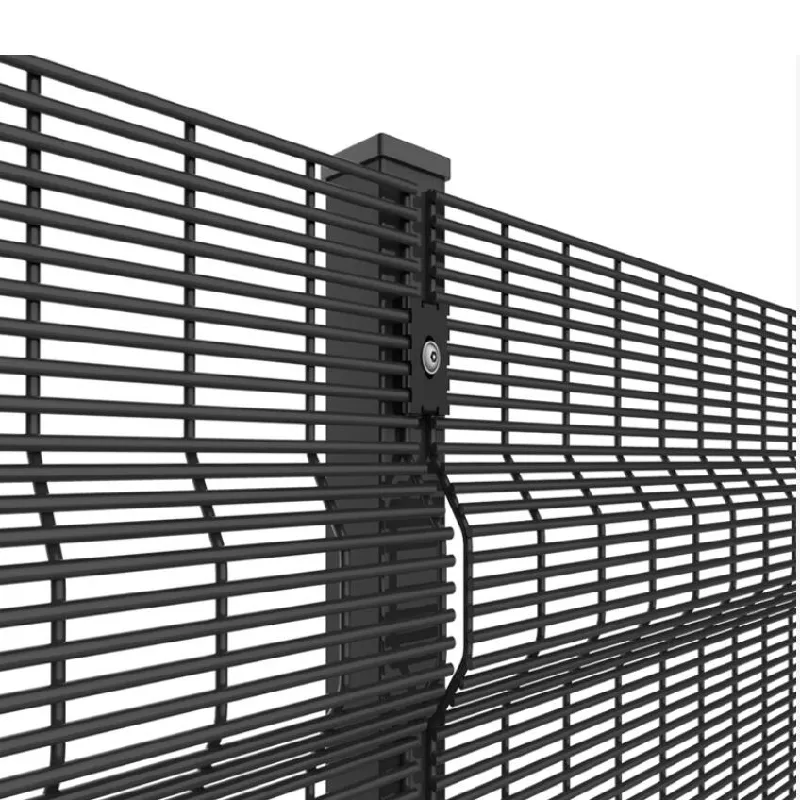

In today's complex security landscape, the demand for robust, reliable, and impenetrable perimeter solutions is paramount for critical infrastructure, correctional facilities, and high-value commercial sites. Among the myriad of security fencing options available, the wholesale 358 anti-climb fence stands out as a superior choice, widely recognized for its exceptional deterrent capabilities and structural integrity. Often referred to simply as "prison mesh" or "anti-climb fence," this innovative fencing system derives its name from its precise mesh aperture dimensions: 3 inches by 0.5 inches, with an 8-gauge wire diameter (approximately 76.2mm x 12.7mm x 4mm). This extremely tight mesh configuration effectively prevents human finger and toe holds, making it virtually impossible to climb or cut with standard hand tools, thus providing an unparalleled level of security. Its unique design offers clear visibility for surveillance systems while maintaining formidable physical security, a critical balance for modern security applications. The adoption of 358 anti climb fence solutions reflects a global shift towards proactive and preventive security measures, ensuring assets and personnel are safeguarded against unauthorized access and vandalism. This segment of the market continues to expand, driven by increased security threats and the need for durable, low-maintenance barriers in sectors such as petrochemical, metallurgy, and water treatment.

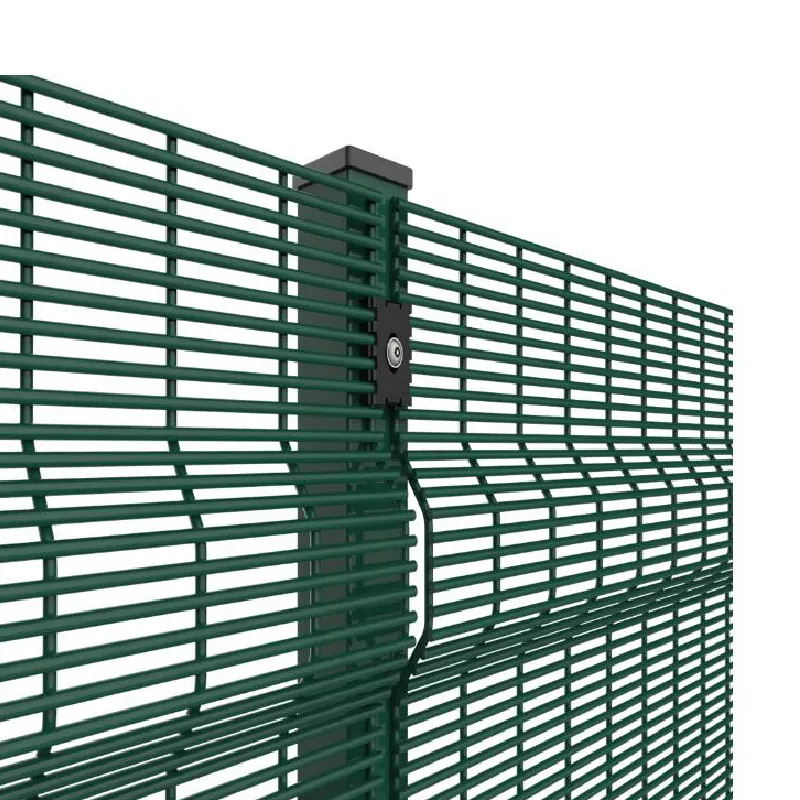

The technological advancements in fencing materials and coating processes have further elevated the performance of the 358 anti climb fence. Modern iterations incorporate high-tensile steel wire, often galvanized, and then optionally powder-coated or pvc coated 358 anti climb fence for enhanced corrosion resistance and aesthetic integration into diverse environments. These coatings not only prolong the service life of the fence, extending it well beyond two decades in many cases, but also contribute to its visual appeal, making it suitable for both high-security and public-facing installations. Understanding the intricate technical parameters and manufacturing precision involved in producing a high-quality 358 anti climb fence is crucial for B2B buyers seeking to procure reliable perimeter security solutions. This article delves into the core aspects of this advanced fencing system, exploring its technical specifications, manufacturing prowess, diverse applications, and critical factors for sourcing from reputable manufacturers to ensure compliance with international standards such as ISO 9001 and ASTM F2781. We aim to provide a comprehensive guide for procurement specialists, project managers, and security professionals, empowering them to make informed decisions when investing in state-of-the-art security barriers that offer advantages like energy efficiency in lighting integrations and superior anti-corrosion properties.

Technical Specifications and Unrivaled Advantages of 358 Mesh

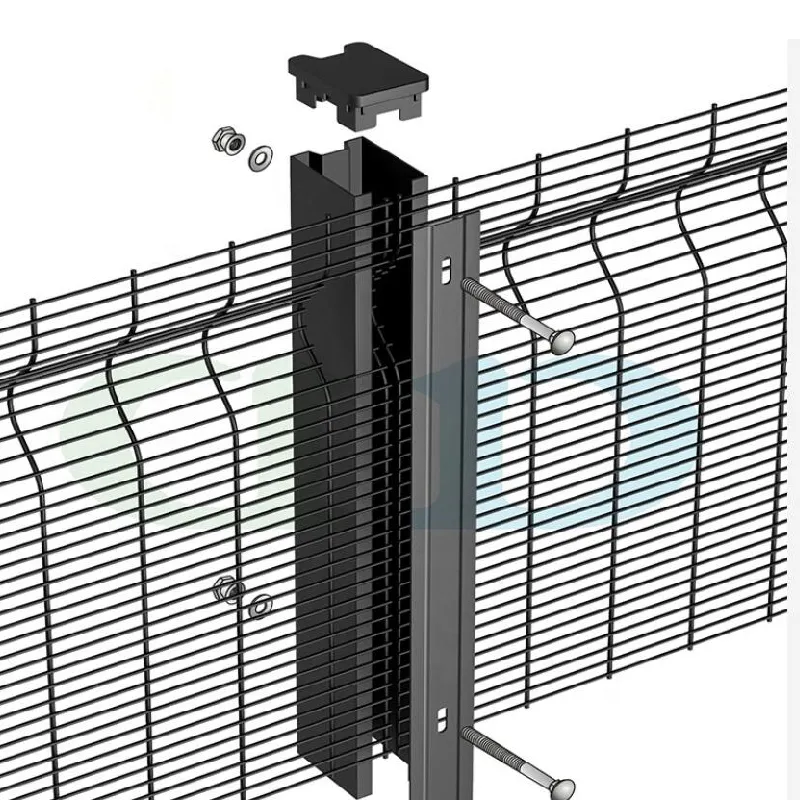

The effectiveness of a 358 anti climb fence hinges on its meticulously engineered technical specifications, which are designed to offer maximum security while maintaining visual permeability. The designation "358" itself refers to the mesh opening size: 3" x 0.5" (approximately 76.2mm x 12.7mm) and 8 gauge wire (4mm diameter). This specific configuration ensures that no foot or finger holds can be gained, and the small apertures prevent the passage of tools such as bolt cutters, thereby thwarting cutting attempts. The strength of the fence is further augmented by the high-quality carbon steel wire used, typically with a minimum tensile strength of 500-700 MPa, ensuring resistance to impact and deformation. Panel heights typically range from 1.8 meters to 5.2 meters, with widths around 2.5 meters, though custom dimensions are readily available to meet specific project requirements. Posts, usually square hollow sections (SHS) or rectangular hollow sections (RHS), are specified to match the fence height and wind load requirements, often ranging from 60x60mm to 100x100mm, with wall thicknesses of 2.5mm to 5.0mm.

Surface treatment is a critical factor determining the longevity and aesthetic appeal of the fence. Hot-dip galvanization, conforming to ASTM A123 or ISO 1461 standards, provides a robust zinc coating of typically 60-80 g/m², offering superior corrosion protection, especially in harsh coastal or industrial environments. For enhanced durability and color customization, a subsequent polyester powder coating or PVC coating is applied over the galvanized layer. This dual-layer protection system, particularly for a pvc coated 358 anti climb fence, can extend the fence's lifespan to over 25 years under normal conditions, significantly reducing maintenance costs over its operational period. Industries such as petrochemicals, power generation, public utilities, and transportation infrastructure widely adopt 358 mesh due to its intrinsic anti-climb properties and resistance to sabotage. Its advantages extend beyond mere physical deterrence; the clear sightlines it provides are invaluable for CCTV surveillance, allowing security personnel unobstructed views of the perimeter. This combination of physical barrier and surveillance support makes the wholesale 358 anti-climb fence an intelligent investment for long-term security infrastructure.

The Precision Manufacturing Process of 358 Anti Climb Fence

The production of a high-quality 358 anti climb fence involves a meticulous, multi-stage manufacturing process that prioritizes precision, material integrity, and coating excellence. It begins with the selection of high-grade steel wire, typically low-carbon steel or galvanized steel wire, which must meet stringent quality criteria for tensile strength and ductility. The wire coils are fed into automated welding machines, which precisely resistance-weld the horizontal and vertical wires at their intersections. This process, unlike traditional weaving, creates an incredibly strong and rigid mesh panel that is difficult to deform or cut. The specific welding parameters are critically controlled to ensure consistent mesh aperture (76.2mm x 12.7mm) and strong weld points, which are paramount to the fence's anti-climb and anti-cut properties. Post-welding, the panels undergo a rigorous inspection for weld integrity, dimensional accuracy, and surface imperfections, ensuring compliance with internal quality controls and international standards like ASTM F2781 and ISO 9001.

Following the initial fabrication, the panels proceed to the surface treatment stage, which is crucial for corrosion resistance and durability. For hot-dip galvanized fences, panels are thoroughly cleaned and degreased before immersion in a molten zinc bath, ensuring uniform coating thickness. For pvc coated 358 anti climb fence, panels are often first galvanized and then pre-treated with a chemical wash to ensure maximum adhesion of the subsequent powder coating or PVC layer. The powder coating process involves electrostatically applying a fine polymer powder, which is then cured in an oven at high temperatures (typically 180-200°C) to form a hard, durable, and aesthetically pleasing finish. PVC coating involves a similar process where the galvanized fence is dipped into a fluidized bed of PVC powder or liquid PVC, creating a thick, protective layer that offers exceptional corrosion and UV resistance. Each finished panel undergoes a final inspection for coating thickness, adhesion, and overall finish quality before packaging. This multi-layered protection system ensures that the wholesale 358 anti-climb fence not only meets but often exceeds the expected service life, providing long-term value and security for demanding applications in sectors such as corrections, border security, military installations, and high-security data centers.

Diverse Applications and Industry Adoption of 358 Mesh

The versatility and high-security attributes of the 358 mesh make it an ideal solution for a wide array of applications across various industries. Its primary use is in environments where preventing unauthorized access and deterring intrusion is critical. Correctional facilities, prisons, and mental health institutions rely heavily on 358 anti climb fence systems due to their non-climbable and anti-cut characteristics, which significantly enhance inmate containment and public safety. Similarly, military bases and government installations, requiring robust perimeter security against potential threats, extensively deploy these fences. Beyond these high-security applications, the wholesale 358 anti-climb fence is increasingly specified for critical national infrastructure projects. This includes power stations, substations, water treatment plants, gas pipelines, and communication centers, where asset protection and continuity of service are paramount. The fence's design allows for excellent visibility, crucial for surveillance systems, without compromising physical security, making it a preferred choice for integrated security solutions.

Furthermore, the aesthetic adaptability of the 358 anti climb fence, especially when provided as a pvc coated 358 anti climb fence in various colors, allows it to be integrated into commercial and public spaces without appearing overly imposing. Airports, railway lines, bridges, schools, and even high-end residential estates are adopting 358 mesh for its balance of security and discreet presence. Its ability to maintain clear sightlines is also beneficial for wildlife exclusion along highways or sensitive ecological zones. The longevity of a well-manufactured wholesale 358 anti-climb fence, coupled with its minimal maintenance requirements, offers a compelling total cost of ownership (TCO) advantage over its lifespan. This long-term economic benefit, combined with its superior security performance, positions 358 mesh as a strategic investment for organizations seeking to future-proof their security infrastructure against evolving threats. Client feedback consistently highlights the peace of mind and operational efficiency gained from deploying these advanced fencing solutions, affirming their indispensable role in modern security strategies.

Sourcing Excellence: A Comparative Analysis for Wholesale 358 Anti-Climb Fence

Selecting the right supplier for wholesale 358 anti-climb fence is a critical decision that impacts not only the initial investment but also the long-term performance and reliability of your security infrastructure. Manufacturers vary significantly in their production capabilities, quality control protocols, and adherence to international standards. When evaluating potential suppliers, it is imperative to look beyond just unit cost and consider factors such as material traceability, manufacturing precision, coating quality, and post-sales support. Reputable manufacturers will provide clear documentation of their raw material sourcing, often specifying high-tensile steel that meets or exceeds ASTM A641 or equivalent standards. Their production facilities should ideally be ISO 9001 certified, demonstrating a commitment to consistent quality management processes. Furthermore, the expertise of a manufacturer in handling large-scale B2B orders, offering flexible customization options, and ensuring timely delivery is paramount for seamless project execution.

A key differentiator among suppliers is their coating technology. While hot-dip galvanization is standard, the quality and thickness of the zinc coating can vary, directly impacting corrosion resistance. For projects requiring extreme durability, a pvc coated 358 anti climb fence or a dual-layer powder-coated system over galvanization offers superior protection against environmental degradation and UV exposure. Suppliers should provide verifiable test data, such as salt spray tests (ASTM B117), UV resistance tests, and coating adhesion tests, to substantiate their claims. Experience matters; manufacturers with a long service history (e.g., over 15-20 years in the industry) and a robust portfolio of successful projects globally often possess the necessary expertise to handle complex security requirements. They are more likely to offer comprehensive technical support, installation guidance, and warranty commitments that reflect confidence in their product's longevity and performance. Partnering with such a provider ensures not only a high-quality product but also a reliable supply chain and ongoing support, crucial for large-scale procurement of 358 anti climb fence systems.

Essential Parameters for Wholesale 358 Anti-Climb Fence Procurement

When procuring wholesale 358 anti-climb fence, a detailed understanding of key product parameters is essential for making informed decisions that align with project specifications and security objectives. The following table summarizes critical specifications, typical ranges, and relevant industry standards, providing a clear benchmark for evaluation. These parameters directly influence the fence's performance, durability, and suitability for various applications, from high-security correctional facilities to sensitive industrial sites. Factors such as wire diameter and mesh aperture determine the anti-climb and anti-cut efficacy, while coating type and thickness dictate the fence's longevity and resistance to environmental factors. Manufacturers should be able to provide detailed data sheets and certification for each of these parameters, ensuring transparency and compliance.

| Parameter | Typical Range/Value | Industry Standard/Requirement | Impact on Performance |

|---|---|---|---|

| Mesh Aperture (H x W) | 76.2mm x 12.7mm (3" x 0.5") | Fixed for 358 standard | Prevents finger/toe holds and tool access. Critical for anti-climb feature. |

| Wire Diameter | 4.0mm (8 Gauge) | ASTM A641, ISO 16120 | Resistance to cutting and impact deformation. |

| Tensile Strength | 500-700 MPa | ASTM A641, EN 10218 | Overall strength, resistance to bending/breaking. |

| Panel Height | 1.8m to 5.2m (custom available) | Project Specific | Level of perimeter deterrence. |

| Panel Width | 2.0m to 3.0m (typically 2.5m) | Project Specific | Ease of installation, modularity. |

| Coating Type | Hot-dip Galvanized, PVC Coated, Powder Coated | ASTM A123/A641, ISO 1461, ASTM D3359 | Corrosion resistance, UV protection, aesthetic. |

| Coating Thickness (Galvanized) | 60-80 g/m² minimum | ASTM A123, ISO 1461 | Corrosion protection, service life. |

| Coating Thickness (PVC/Powder) | 80-120 microns | ASTM D3359, EN 13438 | Enhanced corrosion, UV resistance, color retention. |

| Post Dimensions | 60x60mm to 100x100mm (SHS/RHS) | Project Specific, Structural Calc. | Structural stability, wind load resistance. |

This table serves as a guide for preliminary selection and detailed inquiry. For a comprehensive proposal, it is always recommended to consult with the manufacturer, providing specific project parameters such as environmental conditions, required security level (e.g., CPNI classification for critical national infrastructure in the UK), local building codes, and desired accessories like razor wire, barbed wire, or electronic detection systems. Reputable manufacturers of 358 mesh will offer full technical support to help integrate these parameters into a customized fencing solution, ensuring optimal performance and cost-efficiency for your specific needs.

Customization and Project-Specific Solutions for 358 Anti-Climb Fence

While standard panels and specifications for 358 anti climb fence cater to a broad range of security needs, many large-scale or specialized projects require bespoke solutions. Leading manufacturers understand this necessity and offer extensive customization options to ensure the fencing system integrates seamlessly with existing infrastructure and meets unique site challenges. Customization can encompass various aspects, including non-standard panel heights and widths to fit unusual perimeters or to accommodate specific topographical features. For instance, projects requiring extended heights for enhanced deterrence around highly sensitive zones, or narrower panels to navigate complex architectural layouts, can be precisely fabricated. The ability to specify precise post dimensions, base plates for concrete mounting, or specific anchoring systems for various ground conditions is also crucial for ensuring structural integrity and ease of installation.

Beyond physical dimensions, aesthetic customization, particularly for a pvc coated 358 anti climb fence, allows clients to select specific RAL colors to match brand guidelines, environmental aesthetics, or local planning requirements. This is particularly relevant for commercial properties, schools, or public amenities where functionality must coexist with visual appeal. Furthermore, integrated security features such as pre-installed razor wire or barbed wire extensions, specialized gate systems (e.g., sliding gates, swing gates, automated access control gates), and mounting points for CCTV cameras or lighting can be incorporated during the manufacturing phase. This holistic approach ensures that the wholesale 358 anti-climb fence system is not merely a barrier but a fully integrated security solution. Partnering with a manufacturer capable of delivering these tailored solutions, often demonstrated through successful case studies in diverse sectors like airports, correctional facilities, and large industrial parks, is vital for realizing optimal security outcomes and long-term operational efficiency. This collaborative approach minimizes on-site modifications, reduces installation time, and ensures that the final product perfectly aligns with the project's demanding specifications.

Quality Assurance, Certifications, and Trustworthiness

The trustworthiness of a supplier for wholesale 358 anti-climb fence is built upon a foundation of rigorous quality assurance and adherence to international certifications. For B2B clients, verifying these credentials is not just a formality but a critical step in de-risking procurement and ensuring product reliability. Look for manufacturers who hold ISO 9001 certification, which signifies a robust quality management system covering design, development, production, installation, and service. This certification provides an independent assurance that the company consistently meets customer and regulatory requirements. Beyond general quality management, specific product certifications and adherence to industry standards are paramount. For steel wire and fencing products, compliance with ASTM (American Society for Testing and Materials) standards such as ASTM A641 (Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire) and ASTM F2781 (Standard Specification for 358 Mesh Anti-Climb Security Fence System) is essential. European standards like EN 10218 for steel wire and EN 13438 for powder coatings are also strong indicators of quality.

A transparent manufacturer will readily provide material test reports, mill certificates, and third-party inspection reports for their 358 anti climb fence products. These documents detail the chemical composition, mechanical properties (e.g., tensile strength, yield strength), and coating thickness, providing objective data to support claims of product quality. Longevity and performance are also underpinned by comprehensive warranty commitments, typically ranging from 10 to 25 years for corrosion resistance, depending on the coating type (e.g., hot-dip galvanized vs. pvc coated 358 anti climb fence). A clear delivery schedule and logistics plan, especially for large volume orders, reflect a manufacturer's commitment to timely project completion. Moreover, responsive customer support, including technical assistance before, during, and after installation, signifies a reliable partner. Companies with a long track record (e.g., 20+ years of operation) and a global client base often demonstrate this level of authoritativeness and trustworthiness through consistent service and product excellence, making them ideal partners for critical security infrastructure projects requiring wholesale 358 anti-climb fence solutions.

Frequently Asked Questions (FAQ)

Q1: What makes a 358 anti climb fence 'anti-climb' and 'anti-cut'?

The anti-climb characteristic stems from its extremely tight mesh aperture, typically 76.2mm x 12.7mm (3" x 0.5"). This dimension is too small to allow human fingers or toes to gain purchase, effectively preventing climbing. The 'anti-cut' feature is due to the small mesh openings, which deny access to standard cutting tools like bolt cutters or wire cutters, making it incredibly difficult and time-consuming to breach. Furthermore, the high tensile strength of the 4mm (8 gauge) wire contributes significantly to its resistance against cutting and deformation, providing a formidable physical barrier against intrusion attempts.

Q2: What is the typical service life of a wholesale 358 anti-climb fence?

The service life of a 358 anti climb fence largely depends on its surface treatment. A hot-dip galvanized fence can typically last 15-20 years in most environments. However, a pvc coated 358 anti climb fence, which benefits from an additional layer of durable polymer coating over the galvanization, can extend its lifespan to 20-25 years or even longer, especially in corrosive environments or areas with high UV exposure. Regular inspection and minimal maintenance can help maximize its operational longevity, ensuring a long-term return on investment for your security infrastructure.

Q3: Can 358 mesh be customized for specific project requirements?

Absolutely. Reputable manufacturers offer extensive customization for 358 mesh. This includes custom panel heights and widths, specific post dimensions and mounting options, and a wide range of RAL colors for powder or PVC coating to match aesthetic or environmental requirements. Additionally, integration of advanced security features such as razor wire, barbed wire extensions, CCTV camera mounts, and various gate types (swing, sliding, automated) can be incorporated during the manufacturing process to provide a comprehensive, tailored security solution.

Q4: What certifications should I look for when sourcing a wholesale 358 anti-climb fence?

When sourcing, prioritize manufacturers with ISO 9001 certification for quality management. For the product itself, look for compliance with relevant material and performance standards such as ASTM A641 (for galvanized wire), ASTM F2781 (for 358 mesh systems), ISO 1461 (for hot-dip galvanization), and ASTM D3359 (for coating adhesion). These certifications and standards ensure that the product meets high-quality benchmarks for materials, manufacturing processes, and protective coatings, guaranteeing reliability and performance.

Q5: What are the typical lead times for a large order of 358 anti climb fence?

Lead times for wholesale orders of 358 anti climb fence can vary significantly based on order volume, customization requirements, and the manufacturer's current production schedule. Typically, for standard configurations and moderate volumes, lead times might range from 3 to 6 weeks. For very large or highly customized orders, this could extend to 8-12 weeks or more. It is crucial to communicate your project timelines clearly with the manufacturer at the outset to establish a realistic delivery schedule. Reputable suppliers will provide a transparent production and logistics plan, ensuring timely delivery and minimal project delays.

Conclusion: Strategic Investment in Advanced Perimeter Security

The deployment of a wholesale 358 anti-climb fence represents a strategic and forward-thinking investment in advanced perimeter security. Its unparalleled anti-climb and anti-cut properties, combined with excellent visibility for surveillance, make it the preferred choice for a multitude of high-security and critical infrastructure applications. From correctional facilities and military installations to power plants and data centers, the 358 anti climb fence consistently delivers robust protection against intrusion and vandalism. The meticulous manufacturing process, involving high-grade materials and advanced coating technologies like hot-dip galvanization and PVC coating, ensures exceptional durability and a prolonged service life, offering a superior total cost of ownership.

For B2B buyers, understanding the technical specifications, evaluating manufacturing capabilities, and verifying certifications are crucial steps in sourcing high-quality 358 mesh. Partnering with experienced and authoritative manufacturers who offer customization, comprehensive technical support, and solid warranty commitments will ensure that your security infrastructure meets the highest standards of reliability and effectiveness. As security threats continue to evolve, investing in proven, technologically advanced solutions like the wholesale 358 anti-climb fence is not merely a defensive measure but a proactive strategy to safeguard critical assets and ensure operational continuity. DQ Fence, with its extensive expertise and commitment to quality, stands as a reliable partner in delivering these essential security solutions.

References

- ASTM International. "ASTM F2781/F2781M-19 - Standard Specification for 358 Mesh Anti-Climb Security Fence System."

- International Organization for Standardization. "ISO 9001:2015 - Quality management systems – Requirements."

- British Standards Institution. "BS EN 10218-1:2012 - Steel wire and wire products. General. Test methods for wire."

- ASTM International. "ASTM A123/A123M-17 - Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products."

- The Powder Coating Institute. "Powder Coating: The Definitive Guide for Specifiers and Users."

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025