- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

আগস্ট . 21, 2025 21:00 Back to list

Shop Bulk T Posts for Sale | Wholesale Metal & Steel Fence Posts

Strategic Procurement of Bulk T Posts: A Comprehensive Guide for Industrial Buyers

In large-scale infrastructure projects, agricultural developments, and various industrial applications, the demand for durable, cost-effective fencing solutions is paramount. Among the most widely adopted and reliable components are T-posts, known for their exceptional strength, longevity, and ease of installation. For organizations requiring substantial quantities, the strategic procurement of bulk t posts for sale represents a critical decision influencing project timelines, budget adherence, and long-term asset performance. This comprehensive guide delves into the technical intricacies, manufacturing processes, application scenarios, and key considerations for B2B buyers seeking to optimize their sourcing strategy for T-posts. We aim to provide an expert-level understanding, empowering informed decisions that align with stringent project requirements and sustainability goals.

Understanding the nuanced aspects of material composition, surface treatments, and structural integrity is vital for ensuring the chosen T-posts meet specific operational demands, from resisting harsh environmental conditions to supporting heavy-duty fencing systems. This article will navigate through industry standards, performance metrics, and the advantages of securing high-quality T-posts through reliable wholesale channels.

Understanding T-Posts: Materials, Types, and Structural Integrity

T-posts, also commonly referred to as studded T-posts or simply metal fence posts, derive their name from their distinctive T-shaped cross-section. This unique profile is engineered to provide superior strength-to-weight ratio, preventing bending and twisting under significant lateral loads, a common challenge in agricultural, industrial, and perimeter security fencing.

Core Materials and Their Properties

The primary material for high-quality T-posts is typically high-strength steel, often sourced from recycled rail steel, which inherently possesses excellent mechanical properties due to its prior application in demanding railway environments. Common material specifications include ASTM A702, which covers steel fence posts and assemblies. The choice of steel grade significantly impacts the post's yield strength and tensile strength, directly correlating with its ability to withstand external forces without permanent deformation or failure.

- High-Carbon Steel: Offers superior rigidity and strength, making it ideal for robust applications. Its inherent hardness contributes to excellent resistance against impact and bending.

- Rail Steel: Repurposed from railway tracks, this material is known for its exceptional durability and fatigue resistance, providing a sustainable and high-performance option for bulk t posts for sale.

- Low-Carbon Steel: While less strong, it offers better ductility and formability, though less common for structural T-posts unless specific applications require greater flexibility.

Surface Treatments and Corrosion Resistance

To extend the service life of T-posts, especially in challenging outdoor environments, various surface treatments are applied. These treatments are crucial for preventing corrosion, which can significantly compromise the structural integrity of steel over time.

- Green Paint (Enamel or Powder Coating): A common and cost-effective treatment, providing a basic level of protection against rust and often chosen for its aesthetic blend with natural landscapes. While offering initial protection, its longevity is less than metallic coatings.

- Hot-Dip Galvanization: This is the gold standard for corrosion protection. Posts are submerged in molten zinc, creating a metallurgically bonded coating that acts as a barrier and provides cathodic protection (sacrificial anode effect) if the coating is scratched. Hot-dip galvanized steel t posts for sale offer decades of maintenance-free service, even in harsh coastal or high-humidity environments. This process adheres to standards like ASTM A123/A123M for zinc coatings.

- PVC Coating: Less common but provides excellent chemical resistance and a smooth finish, often used in specific industrial or agricultural settings where aggressive chemicals might be present.

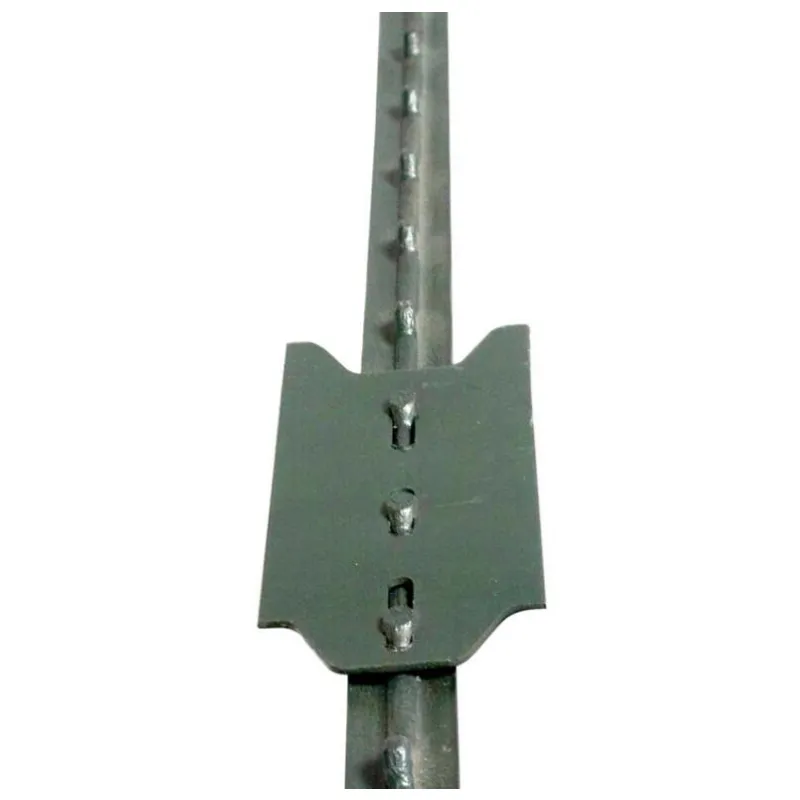

Figure 1: Diverse T-post options showcasing various lengths and protective coatings, including hot-dip galvanized and painted finishes.

Stud Design and Functionality

A defining feature of T-posts is the presence of evenly spaced studs or nubs along their length. These studs are not merely decorative; they serve a critical functional purpose: securely holding fencing materials (such as barbed wire, woven wire, or electric fence insulators) in place without the need for additional fasteners like staples, thus simplifying installation and reducing labor costs. The design ensures that the fence fabric remains taut and stable, even under environmental stresses like wind or animal pressure.

The Manufacturing Process: Precision Engineering for Durability

The production of high-quality T-posts involves a meticulously controlled manufacturing process, emphasizing material integrity, precise shaping, and robust surface treatments. While the prompt mentioned casting, forging, and CNC, T-posts are predominantly manufactured through a hot-rolling process, a highly efficient method for producing long, uniform steel sections. The precision achieved in this process, coupled with stringent quality control, rivals the accuracy expected from other advanced manufacturing techniques.

Detailed Manufacturing Workflow:

- 1. Raw Material Sourcing & Preparation: The process begins with selecting high-grade steel billets, often recycled rail steel or specific high-carbon steel alloys. These billets are inspected for metallurgical defects and cut to appropriate lengths for the rolling mill.

- 2. Heating & Hot Rolling: Steel billets are heated to extreme temperatures (typically 1,100-1,250°C or 2,000-2,280°F) in a re-heating furnace. This makes the steel ductile for shaping. The heated billets then pass through a series of rolling stands, each progressively shaping the steel into the characteristic T-profile. This multi-pass rolling ensures dimensional accuracy and enhances the steel's grain structure, contributing to its ultimate strength and resilience.

- 3. Punching & Studding: As the T-post cools slightly, specialized machinery punches the iconic studs or nubs along one flange. This operation requires precise timing and alignment to ensure uniform spacing and robust stud formation, critical for securely holding fence wire. In some cases, pre-punched holes for specific attachments might also be incorporated.

- 4. Cutting & Straightening: The continuous T-section is cut to specified lengths (e.g., 5 ft, 6 ft, 7 ft, 8 ft, 10 ft for 6 foot steel t posts for sale and other lengths). After cutting, posts may undergo a final straightening process to eliminate any minor warps or bends, ensuring they are perfectly plumb for installation.

- 5. Post-Rolling Treatment (Surface Finishing):

- Painting: Posts are typically cleaned and then sprayed with a weather-resistant enamel or powder coating, usually green or black, for basic protection and aesthetics.

- Hot-Dip Galvanization: For superior corrosion resistance, posts are meticulously cleaned (degreased, pickled in acid, fluxed) before being immersed in a bath of molten zinc (around 450°C or 850°F). The metallurgical bond formed between steel and zinc provides a durable, long-lasting protective layer conforming to ASTM A123/A123M standards, ideal for metal t post for sale that demand extended outdoor exposure.

- 6. Quality Control & Inspection: Each batch undergoes rigorous inspection. This includes dimensional checks (length, T-section dimensions), visual inspection for surface defects, and coating thickness measurements (for galvanized posts, using magnetic or eddy current gauges). Material samples may be subjected to mechanical testing (tensile strength, yield strength) to confirm compliance with industry standards like ISO 9001 for quality management and ASTM A702 for post specifications.

Figure 2: Advanced machinery involved in the precision manufacturing process of T-posts, ensuring consistency and quality.

The emphasis on precise hot-rolling and quality control measures at every stage ensures that each T-post meets stringent performance criteria, contributing to an extended service life often exceeding 20-30 years for galvanized variants, even in demanding environments.

Key Technical Parameters and Specifications for Bulk T Posts

Selecting the right T-post involves understanding a range of technical specifications that directly impact their suitability for specific applications and their long-term performance. For wholesale t posts, consistency in these parameters is paramount.

Standard T-Post Specifications Table

The following table provides common parameters for T-posts, derived from typical industry offerings and performance requirements. Actual specifications may vary slightly between manufacturers but generally adhere to these ranges.

| Parameter | Description / Range | Industry Standard (Example) |

|---|---|---|

| Material Grade | High-strength steel, often recycled rail steel. Carbon content typically 0.6-0.8%. | ASTM A702 (Standard Specification for Steel Fence Posts and Assemblies, Hot-Wrought) |

| Length Options | 5 ft (1.52m), 6 ft (1.83m), 7 ft (2.13m), 8 ft (2.44m), 10 ft (3.05m). Custom lengths available. | Manufacturer Specifications |

| Weight per Foot (Nominal) | 1.25 lbs/ft (1.86 kg/m), 1.33 lbs/ft (1.98 kg/m), 2.00 lbs/ft (2.98 kg/m). Higher weight implies greater strength. | ASTM A702 |

| Coating Type | Green Painted (Enamel), Hot-Dip Galvanized, PVC Coated. | ASTM A123/A123M (Galvanization), Manufacturer's Standards |

| Zinc Coating Weight (Galvanized) | Typically 1.8 oz/ft² (550 g/m²) for heavy galvanized. Lower for light galvanized. | ASTM A123/A123M |

| Yield Strength | Minimum 50,000 psi (345 MPa) up to 70,000 psi (480 MPa) depending on steel grade. | ASTM A702 |

| Tensile Strength | Minimum 80,000 psi (550 MPa) up to 100,000 psi (690 MPa). | ASTM A702 |

| Stud Spacing | Typically 2-3 inches (50-75 mm) apart, ensuring uniform wire attachment. | Manufacturer Specifications |

| Anchor Plate | Welded on for increased stability and resistance to uplift or lateral forces. Dimensions vary. | Manufacturer Specifications |

| Bundle Quantity | Typically 5 or 10 posts per bundle, with pallet quantities ranging from 200 to 500 posts. | Logistical Packaging Standards |

Understanding these parameters is crucial for project managers and procurement specialists. For instance, in soft soil conditions or areas prone to high winds, a higher weight per foot and a robust anchor plate are critical. Similarly, for projects in corrosive environments (e.g., coastal regions, industrial zones), hot-dip galvanized metal t post for sale are an absolute necessity to ensure long-term integrity and minimize maintenance costs.

Versatile Applications Across Diverse Industries

The robust design and adaptability of T-posts make them indispensable across a wide array of industries. Their utility spans from demarcation and security to supporting complex agricultural systems.

Key Application Scenarios and Advantages:

- Agriculture and Livestock Management: This is arguably the largest sector for T-posts. They are used for perimeter fencing, rotational grazing paddocks, animal enclosures (cattle, sheep, horses), and vineyard trellising. The ease of driving them into various soil types and the quick attachment of fence wires make them highly efficient. Hot-dip galvanized posts ensure longevity in pastures exposed to animal waste and harsh weather.

- Forestry and Wildlife Control: For establishing boundaries in timberlands, protecting young saplings from browsing animals, or creating controlled wildlife corridors. The strength of steel t posts for sale resists pressure from deer and other large animals.

- Construction Sites: Temporary site demarcation, security fencing, safety barrier support around excavations, and storage areas. Their reusability and quick installation are significant advantages.

- Infrastructure Projects (Roads, Railways, Utilities): Used for right-of-way demarcation, establishing property lines along highways and rail tracks, and protecting sensitive utility equipment. Their minimal footprint and high visibility are beneficial.

- Security and Perimeter Protection: For commercial properties, industrial parks, and correctional facilities, T-posts form the backbone of security fencing, supporting barbed wire, razor wire, or high-security mesh. The robust nature of a 6 foot steel t post for sale or taller posts deters unauthorized access.

- Landscaping and Garden Projects (Large Scale): For supporting large trellises, creating structured garden areas, or defining expansive property boundaries in commercial landscaping.

- Petrochemical and Industrial Facilities: While direct application as process equipment is limited, T-posts are crucial for perimeter security, internal demarcation of hazardous zones, and supporting temporary barriers during maintenance or expansion. Their inherent corrosion resistance (especially galvanized) is vital in environments with chemical exposure.

- Water Management (Dams, Canals, Reservoirs): Used for fencing off access to water bodies for safety, defining flood plain boundaries, and supporting erosion control measures. The anti-corrosion properties of galvanized metal t post for sale are essential in constantly damp or submerged conditions.

Figure 3: T-posts deployed in a large agricultural setting, demonstrating their utility in expansive perimeter fencing.

Technical Advantages in Application:

- Exceptional Strength-to-Weight Ratio: The T-shape provides significant bending resistance with less material compared to round or square posts, leading to efficient material usage.

- Ease of Installation: Can be driven directly into the ground using a manual post driver, pneumatic driver, or hydraulic machinery, significantly reducing installation time and labor costs compared to digging holes and setting concrete. The anchor plate at the bottom prevents rotation and increases stability.

- Corrosion Resistance: Hot-dip galvanized posts offer superior protection against rust and degradation from environmental exposure, saline conditions, and various chemicals, ensuring long-term structural integrity and minimal maintenance expenditure. This translates directly into energy savings by avoiding frequent repairs and replacements.

- Durability & Longevity: High-strength steel combined with robust coatings results in a product designed for decades of service, even under adverse conditions, making bulk t posts for sale a cost-effective long-term investment.

- Versatile Wire Attachment: The integrated studs allow for quick and secure attachment of various wire types without specialized tools or additional fasteners, streamlining the fencing process.

The Strategic Advantage of Bulk T Post Procurement

For large-scale projects, buying wholesale t posts offers compelling logistical and financial benefits that significantly impact the overall project budget and timeline.

Economic Efficiency and Cost Savings:

- Reduced Unit Cost: Manufacturers and distributors offer substantial discounts for bulk orders. This volume pricing is often the most significant financial advantage, as the per-unit cost drops considerably compared to smaller retail purchases.

- Lower Shipping Costs: Consolidating large quantities into single or fewer shipments dramatically reduces freight expenses. Full truckload (FTL) or full container111 load (FCL) shipping is far more cost-effective per unit than less-than-truckload (LTL) shipments. For example, shipping 10,000 T-posts in one FTL shipment can be 30-50% cheaper per post than shipping 1,000 posts in ten LTL shipments.

- Operational Efficiency: Fewer purchase orders, invoices, and supplier interactions streamline the procurement process, saving administrative time and resources.

Supply Chain Stability and Project Continuity:

- Guaranteed Supply: Securing a large order ensures a consistent and uninterrupted supply of materials throughout the project duration, mitigating risks associated with material shortages or price fluctuations in the spot market.

- Consistent Quality: A single large batch from one manufacturer typically guarantees uniform quality, appearance, and technical specifications across all posts. This consistency is vital for large-scale projects where variations can lead to installation issues or long-term performance disparities.

- Reduced Lead Times: Established relationships with bulk suppliers often lead to prioritized production slots and faster delivery schedules, crucial for time-sensitive projects.

Figure 4: Palletized bulk t posts for sale, illustrating efficient packaging for large-scale logistics and distribution.

Environmental and Sustainability Benefits:

Many high-quality steel t posts for sale are manufactured from recycled steel, contributing to a circular economy and reducing the carbon footprint associated with new steel production. Choosing a reputable supplier committed to sustainable practices further enhances a project's environmental profile. By opting for durable, long-lasting products like hot-dip galvanized T-posts, projects also reduce future material consumption and waste generation through extended service life.

Vendor Comparison and Selection Criteria for Bulk T Posts

Choosing the right supplier for bulk t posts for sale is as crucial as the product itself. A reliable vendor ensures not only product quality but also logistical efficiency and dependable customer support.

Key Factors for Vendor Evaluation:

- Quality Certifications and Compliance: Verify that the manufacturer adheres to international quality standards such as ISO 9001:2015 for quality management systems. Product-specific certifications (e.g., ASTM A702 for steel posts, ASTM A123/A123M for galvanization) are non-negotiable indicators of product integrity. Ask for material test reports (MTRs) for steel chemical composition and mechanical properties.

- Manufacturing Expertise and Facilities: A vendor with a long history and state-of-the-art manufacturing facilities is more likely to produce consistent, high-quality products. Inquire about their production capacity to ensure they can meet your bulk order demands.

- Material Sourcing Transparency: Understand where their raw materials come from. Suppliers using traceable, high-quality steel (e.g., recycled rail steel or certified virgin steel) often produce superior T-posts.

- Coating Quality and Longevity: For galvanized posts, inquire about the average zinc coating thickness and adherence, which directly correlate with the post's service life. Reputable suppliers will provide data sheets confirming zinc weight per unit area.

- Customization Capabilities: Can the supplier provide specific lengths, coatings, or punching patterns if your project has unique requirements? This flexibility is invaluable for specialized applications.

- Logistics and Delivery: Assess their ability to handle large-volume shipments efficiently. This includes packaging (e.g., secure bundling, palletization), lead times, and shipping reliability to your project site.

- After-Sales Support and Warranty: A strong warranty on their products and responsive customer support are indicators of a trustworthy partner. This includes assistance with technical queries, problem resolution, and claims processing.

- Reputation and References: Seek out client testimonials, case studies, and industry references. A proven track record with other B2B clients in similar sectors speaks volumes about a vendor's reliability.

Figure 5: Rigorous quality inspection of T-posts during the manufacturing process, ensuring adherence to technical specifications.

Pricing and Value Proposition:

While price is always a consideration, it should not be the sole determinant when purchasing bulk t posts for sale. A lower upfront cost for inferior products can lead to significantly higher long-term expenses due to premature failure, increased maintenance, and replacement costs. Evaluate the total cost of ownership (TCO) that includes product lifespan, installation efficiency, and environmental resilience. A slightly higher-priced galvanized T-post, for instance, may offer a 2-3x longer service life than a painted one, translating to substantial savings over decades.

Customization Solutions for Specific Project Needs

While standard T-posts meet most requirements, certain projects demand specific modifications to optimize performance or meet unique environmental or regulatory criteria. Leading manufacturers offering wholesale t posts understand these needs and provide customization options.

Tailoring T-Posts to Your Project:

- Custom Lengths: While standard lengths like 6 ft steel t posts for sale are common, specialized projects (e.g., very tall vineyard trellises, deep soil penetration for stability) may require non-standard lengths.

- Specific Coating Systems: Beyond standard painted or hot-dip galvanized, some applications might require specialized coatings for extreme chemical resistance, specific color requirements for aesthetic or safety coding, or dual-layer systems for enhanced durability.

- Pre-Punched Holes or Attachments: For complex fencing systems that require specific attachment points for sensors, security cameras, or specialized insulators, manufacturers can integrate pre-punched holes or even welded brackets during the production process, reducing on-site fabrication.

- Material Grade Adjustments: For applications demanding exceptionally high tensile strength or specific corrosion resistance (e.g., marine environments requiring stainless steel variants, though rare for T-posts), some manufacturers can source and process specialized steel alloys.

- Anchor Plate Modifications: The size and design of the anchor plate can be customized to provide greater stability in challenging soil conditions or to withstand unusual uplift forces.

- Branding and Marking: For large projects or distributors, the option to include custom branding or specific markings on the posts (e.g., project ID, company logo) can be valuable for inventory management and brand visibility.

Engaging with a manufacturer early in the project planning phase can facilitate these customizations, ensuring that the delivered bulk t posts for sale are perfectly aligned with the project's unique demands, thereby optimizing performance and installation efficiency.

Real-World Application Case Studies

The practical application of bulk t posts for sale demonstrates their versatility and critical role in large-scale endeavors. Here are two hypothetical but representative case studies.

Case Study 1: Large-Scale Solar Farm Perimeter Security

Client: "SunPeak Energy," a leading developer of utility-scale solar farms in the Southwestern United States.

Challenge: SunPeak Energy needed to secure a new 500-acre solar farm against trespassing, vandalism, and wildlife intrusion. The site was characterized by rocky, arid terrain and exposure to high UV radiation and occasional flash floods. Traditional fencing methods were proving too slow and costly.

Solution: After consulting with a specialized fence material supplier, SunPeak opted for bulk t posts for sale, specifically 8-foot, hot-dip galvanized T-posts (1.33 lbs/ft) with heavy-duty anchor plates. A total of 15,000 posts were ordered to establish a robust perimeter fence supporting 7-strand barbed wire and a ground-level anti-dig mesh.

Outcome:

- Installation Efficiency: Utilizing hydraulic post drivers, installation teams could set over 150 T-posts per day, significantly accelerating the project timeline compared to traditional concrete-set posts.

- Durability: The hot-dip galvanization proved highly effective against the corrosive desert environment and intense UV, showing no signs of rust after initial post-installation inspections. The robust T-profile and anchor plates ensured stability in varied soil conditions.

- Cost-Effectiveness: The bulk purchase reduced the unit cost by 18% and freight costs by 25% compared to previous projects using smaller orders, contributing to a 10% overall reduction in fencing expenditure for the farm's perimeter.

- Security Enhancement: The T-post system provided a formidable barrier, effectively deterring wildlife and unauthorized access, ensuring the safety and operational continuity of the solar assets.

Case Study 2: Vineyard Trellis System Expansion

Client: "VineBloom Estates," a vineyard expanding its cultivation by 200 acres in a temperate, high-rainfall region.

Challenge: The expansion required a reliable and durable trellis system to support new grapevines, needing posts that could withstand heavy fruit loads, strong winds, and pervasive moisture without degradation. Consistency in post height and strength was crucial for uniform vine growth.

Solution: VineBloom Estates chose 7-foot, hot-dip galvanized steel t posts for sale (1.25 lbs/ft) with specialized stud patterns optimized for vineyard wire attachment. A total of 10,000 posts were procured in bulk to standardize their trellis infrastructure.

Outcome:

- Longevity and Corrosion Resistance: The hot-dip galvanized coating provided exceptional protection against rust in the humid vineyard environment, ensuring a projected lifespan of over 30 years, significantly reducing future replacement needs.

- Structural Support: The inherent strength of the T-post design, combined with its high-strength steel, comfortably supported the increasing weight of the vines and fruit throughout the growing season, even during periods of heavy winds.

- Ease of Wire Management: The uniform stud spacing allowed for quick and efficient attachment of trellis wires, simplifying the training of young vines and maintenance of mature plants, contributing to streamlined vineyard management practices.

- Scalability: The ability to procure a large, consistent batch of high-quality posts facilitated the rapid and efficient expansion of the vineyard, keeping the project on schedule and within budget.

Quality Assurance, Compliance, and Trustworthiness

In the B2B landscape, trust is built on transparency, adherence to standards, and reliable support. When sourcing bulk t posts for sale, ensuring high standards of quality assurance and compliance is paramount.

Industry Certifications and Testing:

- ISO 9001:2015 Certification: A reputable manufacturer will possess this certification, indicating a robust Quality Management System (QMS) that ensures consistent product quality, processes, and continuous improvement.

- ASTM Standards: Compliance with American Society for Testing and Materials (ASTM) standards is crucial. For T-posts, key standards include:

- ASTM A702: Standard Specification for Steel Fence Posts and Assemblies, Hot-Wrought. This covers the material, mechanical properties (tensile strength, yield strength), and permissible variations in dimensions.

- ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. This ensures the quality and minimum thickness of the galvanized coating, directly influencing corrosion resistance and longevity.

- In-house Laboratory Testing: Leading manufacturers often operate their own accredited laboratories for continuous testing of raw materials and finished products. This includes:

- Chemical Composition Analysis: Using spectrometers to verify steel alloy elements.

- Mechanical Properties Testing: Tensile and yield strength tests ensure the steel can withstand design loads.

- Coating Adhesion Tests: (e.g., knife test, bend test) for galvanized layers to confirm durable bonding.

- Salt Spray Testing (ASTM B117): Accelerated corrosion testing for coatings, predicting long-term performance in corrosive environments.

Warranty and After-Sales Support:

A strong warranty reflects a manufacturer's confidence in their product. Look for warranties that clearly define coverage period and conditions, especially for coating performance. Reputable suppliers offer:

- Clear Warranty Statement: For instance, a 10-year warranty against red rust for galvanized metal t post for sale.

- Dedicated Technical Support: Access to engineering or technical specialists who can answer questions about product specifications, installation, or troubleshoot issues.

- Efficient Claims Process: A streamlined procedure for addressing any potential product defects or shipping damage.

Frequently Asked Questions (FAQ) about Bulk T Posts

Q1: What are the primary advantages of choosing hot-dip galvanized T-posts over painted ones for bulk orders?

A1: Hot-dip galvanized T-posts offer superior corrosion resistance and significantly longer service life, often exceeding 20-30 years in typical environments compared to 5-10 years for painted posts. The molten zinc coating provides both a barrier and cathodic protection, meaning it sacrificially corrodes to protect the underlying steel even if scratched. While the initial cost may be higher, the total cost of ownership (TCO) is generally much lower due to reduced maintenance, repair, and replacement expenses over the product's lifespan. This is especially critical for projects requiring bulk t posts for sale in harsh, humid, or chemically exposed environments.

Q2: How does the weight per foot of a T-post (e.g., 1.25 lbs/ft vs. 1.33 lbs/ft) impact its performance?

A2: The weight per foot is a direct indicator of the amount of steel used in the T-post's construction, and thus, its inherent strength and rigidity. A T-post with a higher weight per foot (e.g., 1.33 lbs/ft or 2.00 lbs/ft) contains more material, leading to increased bending resistance, greater stability, and enhanced durability. These heavier posts are preferred for applications requiring maximum strength, such as heavy-duty livestock fencing, high-security perimeters, or installations in soft soils prone to wind stress. For instance, a 6 foot steel t post for sale weighing 1.33 lbs/ft will be significantly more robust than a 1.25 lbs/ft post of the same length.

Q3: What specific data or certifications should I request from a supplier when buying bulk T-posts?

A3: For full transparency and quality assurance, request the following:

- ISO 9001 Certificate: To verify their Quality Management System.

- Material Test Reports (MTRs): For the steel, indicating chemical composition, yield strength, and tensile strength (e.g., conforming to ASTM A702).

- Galvanization Certificates/Reports: If applicable, confirming zinc coating thickness and weight per unit area (e.g., conforming to ASTM A123/A123M).

- Product Specification Sheets: Detailing dimensions, weight, stud spacing, and any specific features.

- Warranty Statement: Outlining coverage for product defects or coating performance.

- References/Case Studies: From other B2B clients who have purchased wholesale t posts.

Q4: What is the typical delivery lead time for large orders of T-posts?

A4: Delivery lead times for bulk t posts for sale can vary significantly based on order quantity, customization requirements, manufacturer's current production schedule, and shipping destination. For standard specifications, lead times might range from 2-4 weeks for domestic shipments (within the same continent) and 6-12 weeks for international sea freight. Custom orders or very large quantities may require longer lead times (e.g., 8-16 weeks). It's crucial to confirm the estimated delivery schedule with your supplier at the time of quotation and consider factors like port congestion or customs clearance for international orders.

Q5: How are T-posts packaged for bulk shipment, and what are the typical minimum order quantities (MOQ)?

A5: T-posts are typically bundled in quantities of 5 or 10 posts, secured with steel bands. These bundles are then usually palletized, with common pallet quantities ranging from 200 to 500 posts, depending on the post length and weight. Pallets are often wrapped for protection during transit. Minimum Order Quantities (MOQs) for wholesale t posts vary by manufacturer and can range from 1 full pallet (e.g., 200-500 posts) to a full 20-foot or 40-foot container111 (e.g., 10,000-25,000 posts). Larger MOQs generally unlock better unit pricing. It is advisable to clarify the specific MOQs and packaging details with your chosen supplier.

Conclusion: The Smart Investment in Bulk T Posts

The strategic procurement of bulk t posts for sale is a critical decision for any large-scale project requiring robust, long-lasting fencing solutions. From expansive agricultural developments to vital infrastructure and security perimeters, T-posts deliver an unparalleled combination of strength, ease of installation, and cost-effectiveness over their extensive service life. By focusing on key parameters such as high-strength steel material, advanced hot-dip galvanization, and adherence to international standards like ASTM and ISO, buyers can ensure they acquire products that not only meet immediate project requirements but also offer exceptional long-term value.

Partnering with a reputable manufacturer that demonstrates expertise in the complete manufacturing process—from raw material sourcing and precision hot-rolling to rigorous quality control and comprehensive after-sales support—is paramount. Such a partnership guarantees consistent quality, timely delivery, and the availability of customization options crucial for specialized applications. The economic benefits of wholesale t posts, including reduced unit costs and optimized logistics, further underscore the strategic advantage of bulk purchasing. Ultimately, investing in high-quality steel t posts for sale through a trusted supplier translates into projects that are more durable, more efficient, and more sustainable for decades to come.

References

- American Society for Testing and Materials (ASTM). ASTM A702/A702M, Standard Specification for Steel Fence Posts and Assemblies, Hot-Wrought, and Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- International Organization for Standardization (ISO). ISO 9001:2015, Quality Management Systems - Requirements.

- National Association of Steel Pipe Distributors (NASPD). White Paper: The Role of Recycled Steel in Sustainable Infrastructure Development.

- Galvanizers Association. Technical Guide: Durability and Service Life of Hot Dip Galvanized Coatings.

- Fence Industry Association Journal. Article: Advancements in Steel Fence Post Manufacturing and Coating Technologies.

-

Why Welded Gabions Are Redefining Modern Landscape

NewsAug.18,2025

-

Padel Court for Sale

NewsAug.18,2025

-

Modern Open Gable Trellis System

NewsAug.18,2025

-

Guide to Durable and Efficient Fence Post Solutions

NewsAug.18,2025

-

Durable and Affordable Y Post Fence Solutions

NewsAug.18,2025

-

Construction Projects with Reliable Gabion Solutions

NewsAug.18,2025