- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

ডিসে. . 05, 2024 15:01 Back to list

metal grating sizes

Understanding Metal Grating Sizes A Comprehensive Guide

Metal grating has become an essential component in various industries, offering robust solutions for flooring, walkways, and safety applications. Its versatility stems from its design, functionality, and the materials from which it is made. Among these properties, the size and specifications of metal grating are critical factors that influence its effectiveness and suitability for different applications. This article delves into metal grating sizes, providing insights into types, functions, and considerations for selecting the right grating for your needs.

What is Metal Grating?

Metal grating is a framework made of metal bars or sheets, typically arranged in a grid-like pattern and used for a range of purposes. This includes creating elevated walkways, providing drainage, supporting loads, and enhancing safety in environments such as construction sites, industrial facilities, and even residential areas. The materials commonly used for grating include stainless steel, aluminum, and carbon steel, each offering various properties such as corrosion resistance and strength.

Types of Metal Grating

When discussing metal grating sizes, it is important to differentiate between various types of grating. The most common types include

1. Bar Grating This type consists of parallel bars spaced out to allow for drainage and airflow. Bar grating is typically measured by the width, depth, and spacing of the bars. 2. Expanded Metal Grating Made from sheets of metal that have been cut and stretched to form a mesh pattern, this type can be used for flooring and fencing, allowing for visibility while maintaining structural integrity.

3. Woven Wire Grating This type involves a series of wires that are woven together, often used for decorative purposes as well as functional applications in lightweight environments.

4. Safety Grating Often coated or designed with anti-slip surfaces, safety grating is essential in industrial settings where worker safety is paramount.

Size Specifications

The size of metal grating is dictated by several key factors

- Bar Thickness The thickness of the individual bars affects load capacity and durability. Thicker bars can support heavier loads, while thinner bars are lighter and easier to handle.

metal grating sizes

- Width and Spacing The width of the bars and the spacing between them are crucial for determining the overall weight-bearing capabilities of the grating. Standard widths can vary but typically range from 12 to 36 inches. Spacing between bars is often specified to allow for foot traffic and drainage.

- Length Metal grating sections are commonly available in standard lengths, which can be easily fabricated to meet specific project requirements. Standard lengths are often around 10 feet, though custom sizes can be requested.

- Load Ratings Grating is often classified based on its load rating, indicating how much weight it can safely support. Load ratings are determined through testing and certification by relevant standards, such as those set by the American National Standards Institute (ANSI).

Considerations for Choosing the Right Grating Size

When selecting the appropriate metal grating size for a project, several factors need to be considered

1. Application Identify where and how the grating will be used. For instance, grating in areas subject to heavy traffic or machinery use should be chosen to withstand higher loads.

2. Environmental Conditions Corrosion resistance is vital in environments with exposure to moisture or chemicals. Stainless steel or aluminum may be preferred in such scenarios.

3. Safety Standards Always comply with local safety regulations and industry standards when selecting grating, especially for walkways and floors.

4. Aesthetic Considerations In some projects, visual appearance may be important. Choose grating that complements the design and functionality of the area.

Conclusion

Metal grating sizes play a significant role in ensuring the safety and effectiveness of applications across various industries. By understanding the different types of grating, their specifications, and how to select the right size for specific needs, stakeholders can make informed decisions that enhance productivity and safety. As technology and materials advance, the options for metal grating will continue to evolve, offering even more possibilities for innovation and efficiency in design.

-

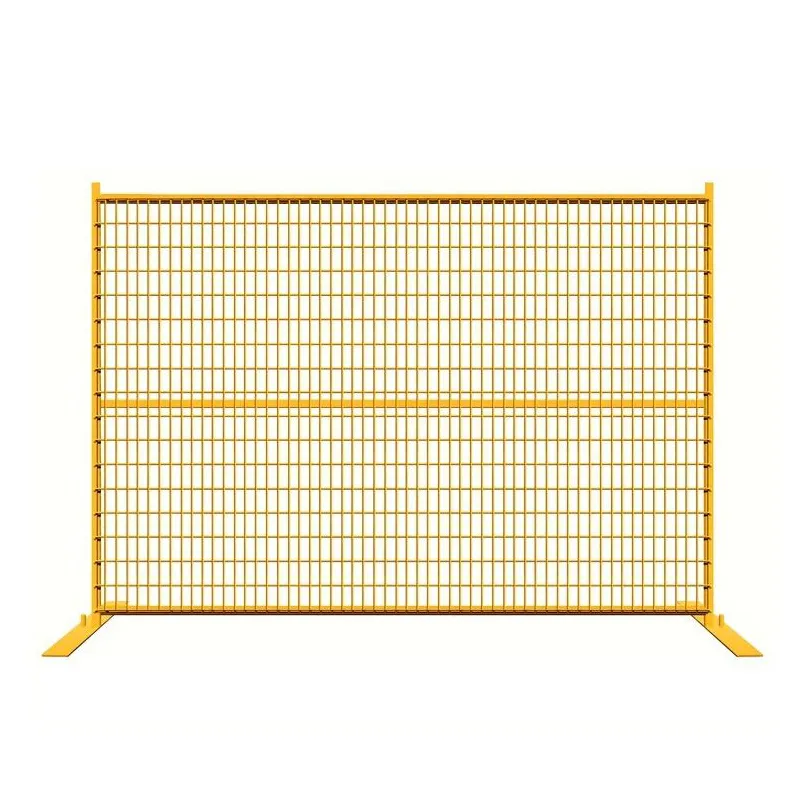

Your Ultimate Solution for Australian Temporary Fencing

NewsMay.14,2025

-

The Ultimate Guide to Crowd Control Barriers: Secure Your Events with Ease

NewsMay.14,2025

-

Secure Your Livestock with High-Quality Livestock Fence Panels

NewsMay.14,2025

-

Enhance Your Livestock Management with Top-Quality Cattle Fences

NewsMay.14,2025

-

Enhance Security and Safety with Temporary Fencing Solutions

NewsMay.14,2025

-

Corral Gates

NewsMay.14,2025