- Afrikaans

- Albanian

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Galician

- Georgian

- German

- Greek

- hawaiian

- Hindi

- Hungarian

- Indonesian

- irish

- Italian

- Lao

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Maltese

- Myanmar

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Somali

- Spanish

- Swedish

- Thai

- Turkish

- Turkmen

- Vietnamese

Dek . 11, 2024 10:19 Back to list

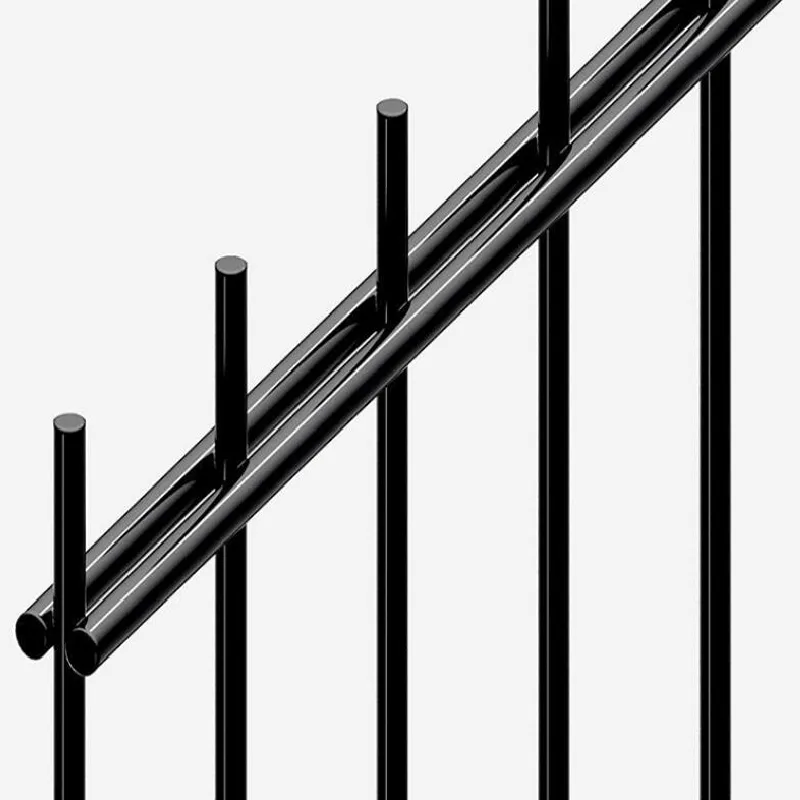

Welded Wire Mesh Panels for Versatile Construction and Industrial Applications

Understanding Welded Metal Mesh Panels Applications, Advantages, and Considerations

Welded metal mesh panels have gained significant popularity across various industries due to their versatility and strength. These panels, constructed by welding together wire strands at cross-sections, create a robust grid structure that can be tailored to fit various needs. This article will explore the applications, advantages, and considerations associated with welded metal mesh panels.

Applications of Welded Metal Mesh Panels

Welded metal mesh panels are used in a multitude of applications, catering to diverse industries such as construction, agriculture, security, and even automotive manufacturing.

1. Construction and Architecture In the construction industry, these panels serve a critical role in reinforcing concrete structures. The mesh is often embedded in concrete to improve structural integrity and prevent cracking. Additionally, they can be used as temporary fencing on construction sites for safety and access control.

2. Agriculture Farmers frequently utilize welded metal mesh panels to create enclosures for livestock or to support crops. These panels provide a reliable barrier against predators while allowing adequate ventilation and sunlight. They can also be used to build trellises for climbing plants, contributing to efficient space utilization.

3. Security From fencing to window guards, welded metal mesh panels are a popular choice for security applications. Their sturdy construction makes them difficult to breach, providing an effective deterrent against intruders. These panels can be coated with various finishes to enhance corrosion resistance, making them suitable for outdoor use.

4. Automotive and Manufacturing In automotive manufacturing, welded metal mesh panels are instrumental in creating specialized racks for parts and tools. They ensure that components are stored securely and organized efficiently, which is crucial for operational productivity.

Advantages of Welded Metal Mesh Panels

1. Strength and Durability One of the primary advantages of welded metal mesh panels is their strength. The welding process creates a solid junction between wire strands, resulting in a product that can withstand significant forces without failing. This durability makes them ideal for harsh environments.

2. Customizability Welded metal mesh panels can be produced in various sizes, shapes, and wire gauges, allowing for customization according to specific application requirements. This flexibility makes them an attractive option for a wide range of uses.

welded metal mesh panels

3. Cost-Effectiveness Compared to other materials, welded metal mesh panels often represent a cost-effective solution. Their longevity and low maintenance requirements translate to reduced overall operational costs.

4. Aesthetic Appeal Many industries are beginning to appreciate the aesthetic value of welded metal mesh panels. They can be used creatively in architectural designs, providing a modern and industrial look that appeals to contemporary tastes.

5. Ease of Installation Generally, welded metal mesh panels are easy to transport and install. Their lightweight nature, combined with pre-fabricated designs, makes them a practical choice for rapid construction and installation processes.

Considerations When Choosing Welded Metal Mesh Panels

While welded metal mesh panels offer numerous benefits, there are certain considerations to keep in mind when selecting the right type for your project

1. Material Selection The material used for the panels should be chosen based on the intended application. Common materials include stainless steel, galvanized steel, and vinyl-coated options, each offering different levels of corrosion resistance and aesthetic appeal.

2. Wire Gauge and Space The gauge of the wire and the spacing of the mesh should align with the specific needs of your application. Thicker gauges and smaller spaces provide greater security but may also increase weight and cost.

3. Environmental Factors Consider the environment in which the panels will be used. Panels exposed to moisture or corrosive elements may require additional coatings or treatments to enhance durability.

4. Compliance and Standards Ensure that the welded metal mesh panels meet relevant industry standards and regulations for safety and performance, particularly in applications related to construction and security.

Conclusion

Welded metal mesh panels represent a highly versatile and robust solution for a variety of applications, from construction and agriculture to security. Their strength, customizability, and cost-effectiveness make them an attractive choice for many industries. However, careful consideration must be given to material choice, wire gauge, and environmental conditions to ensure optimal performance and longevity. As industries continue to evolve, the demand for welded metal mesh panels is likely to grow, solidifying their place as a fundamental component in modern design and functionality.

-

Versatile Sheep and Livestock Hurdles for Sale

NewsApr.14,2025

-

The Rise of BRC Fencing

NewsApr.14,2025

-

High-Quality Cattle and Horse Panels for Sale

NewsApr.14,2025

-

Durable Cattle Fencing Solutions

NewsApr.14,2025

-

Double Wire Fencing Solutions

NewsApr.14,2025

-

360 Degree Protection with 358 Anti-Climb Fences

NewsApr.14,2025